This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3024040 Water Transfer Tube, a component manufactured by Cummins, is integral to the operation of commercial trucks, particularly within the engine cooling system. Understanding its role and functionality is key to maintaining optimal truck performance and longevity.

Basic Concepts and Functionality

Water transfer tubes facilitate the movement of coolant within a truck’s cooling system, connecting various parts of the system to ensure efficient coolant circulation for engine temperature regulation. The 3024040 model by Cummins is designed to enhance the cooling process by providing a reliable pathway for coolant flow, constructed to withstand the pressures and temperatures inherent in a truck’s engine compartment 1.

Purpose of the 3024040 Water Transfer Tube

This Cummins part ensures coolant is effectively distributed throughout the engine, maintaining engine temperature within optimal ranges. This distribution is vital for engine performance and longevity, preventing engine overheating which can lead to significant damage and reduced engine life 2.

Key Features

The 3024040 is characterized by several features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and high temperatures, ensuring longevity and reliable operation. Its design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature unique elements such as reinforced sections or specialized coatings to further improve its durability and efficiency 3.

Benefits

The advantages of the 3024040 include improved cooling efficiency, contributing to maintaining engine temperature within optimal ranges. This efficient cooling can reduce the risk of engine overheating, potentially leading to improved fuel efficiency and reduced emissions. The tube’s durable construction and reliable performance also contribute to overall engine reliability and longevity.

Installation and Integration

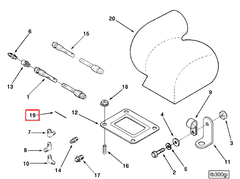

Proper installation of the 3024040 is crucial for its effective operation within a truck’s cooling system. It is designed to be compatible with various components within the system, ensuring seamless integration. Specific guidelines should be followed to ensure the tube is correctly positioned and securely connected, which is vital for optimal performance and to prevent leaks or inefficiencies in the cooling system.

Troubleshooting and Maintenance

Common issues with the 3024040 may include leaks, blockages, or damage due to wear and tear. Diagnostic procedures for identifying these problems involve inspecting the tube for visible signs of damage or wear, checking for leaks in the cooling system, and ensuring all connections are secure. Recommended maintenance practices include regular inspections for signs of wear or damage, cleaning the tube and its connections to prevent blockages, and replacing the tube if significant wear or damage is detected.

Performance and Efficiency

The 3024040 contributes to the overall performance and efficiency of a truck’s engine by ensuring efficient coolant distribution. This efficient cooling helps maintain engine temperature within optimal ranges, which can lead to improved engine reliability and potentially enhance fuel efficiency and reduce emissions. The tube’s role in the cooling system is a key factor in achieving these performance and efficiency benefits.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and excellence, Cummins has established a strong reputation for producing reliable and efficient components. This background underscores the company’s expertise in manufacturing parts like the 3024040, ensuring they meet the high standards required for commercial truck applications.

Role of the 3024040 Water Transfer Tube in Engine Systems

The 3024040 is an essential component in the efficient operation of various engine systems, particularly in marine and industrial applications where cooling and heat management are vital.

Integration with Sea Water Pipe

The Water Transfer Tube is instrumental in the cooling system, where it interfaces with the sea water pipe. This tube facilitates the transfer of cooling water from the sea water pipe to other critical engine components. The efficient flow of cooling water is maintained, ensuring that engine parts remain within optimal temperature ranges, thereby enhancing engine performance and longevity.

Interaction with Turbocharger Mounting

In turbocharged engine systems, the Water Transfer Tube plays a significant role in managing the heat generated by the turbocharger. It ensures that cooling water is effectively circulated around the turbocharger mounting area. This helps in dissipating the heat produced during high-performance operations, thus protecting the turbocharger from overheating and potential damage. The consistent and reliable transfer of cooling water contributes to the overall efficiency and durability of the turbocharger.

The Water Transfer Tube’s design and placement are meticulously engineered to ensure seamless integration with these components, promoting efficient heat management and reliable engine operation.

Conclusion

The 3024040 Water Transfer Tube by Cummins is a critical component in the engine cooling system of commercial trucks. Its role in ensuring efficient coolant distribution contributes to maintaining optimal engine temperature, enhancing engine performance, reliability, and longevity. Proper installation, maintenance, and understanding of its functionality are essential for maximizing the benefits of this part in commercial truck applications.

-

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩ -

Konrad Reif Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Nicholas Goodnight and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.