2883347

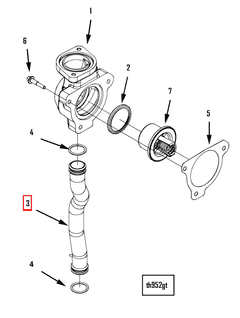

Water Bypass Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Water Bypass Tubes

Water bypass tubes are critical components in commercial truck engines, essential for the efficient management of coolant flow. These tubes ensure that coolant bypasses certain engine areas, preventing overheating and maintaining optimal operating temperatures. This is especially important in heavy-duty applications where engines operate under extreme conditions 2.

The Role of a Water Bypass Tube in Engine Operations

A water bypass tube, such as the Cummins part #2883347, is designed to redirect coolant flow around specific engine components. This redirection is vital in preventing the coolant from overheating certain parts, which could otherwise lead to engine damage. By effectively managing the coolant flow, the water bypass tube helps maintain the engine’s efficiency and longevity, ensuring smooth operation under various load conditions 1.

How the Cummins Water Bypass Tube Works

The Cummins water bypass tube is engineered to channel coolant away from high-temperature zones within the engine. This tube connects various parts of the cooling system, ensuring that the coolant circulates efficiently. The precise design of the water bypass tube allows it to withstand the high pressures and temperatures typical in commercial truck engines. It is constructed from durable materials that resist corrosion and wear, ensuring long-term reliability.

Importance of the Cummins Water Bypass Tube in Truck Operations

In commercial trucks, the water bypass tube plays a critical role in maintaining engine performance. By preventing overheating, it ensures that the engine operates at peak efficiency, which is crucial for long-haul operations. The water bypass tube also contributes to the overall reliability of the truck, reducing the risk of unexpected breakdowns. This is particularly important for fleet operators who rely on consistent performance and minimal downtime 2.

Troubleshooting the Cummins Water Bypass Tube

Regular maintenance and timely troubleshooting are essential for the longevity of the water bypass tube. Engineers and mechanics should inspect the tube for signs of wear, leaks, or blockages. If any issues are detected, such as coolant leaks or reduced flow, the tube should be replaced promptly to avoid engine damage. Early detection and replacement can prevent more severe engine problems and ensure continued optimal performance.

Maintenance Tips for the Cummins Water Bypass Tube

To ensure the water bypass tube functions correctly, it is important to follow a regular maintenance schedule. This includes:

- Regularly checking for leaks or blockages.

- Ensuring the tube is securely connected to all parts of the cooling system.

- Using high-quality coolant to prevent corrosion and buildup within the tube.

- Periodically inspecting the tube for signs of wear or damage and replacing it as necessary.

Cummins: A Leader in Engine Technology

Cummins is renowned for its innovative and reliable engine solutions. The company’s commitment to quality and performance is evident in its water bypass tubes, which are engineered to meet the demanding needs of commercial truck operations. Cummins’ extensive experience and expertise in engine technology make its products a trusted choice for fleet operators. The Cummins water bypass tube part #2883347 exemplifies the company’s dedication to providing high-quality, durable components that ensure engine efficiency and reliability.

Compatibility with Cummins Engines

This Cummins part is designed to fit seamlessly with a range of Cummins engines, ensuring efficient heat management and optimal performance. The Water Bypass Tube 2883347 is compatible with the following engines:

- ISX12 Series: ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250

- ISZ13 Series: ISZ13 CM2150 Z105

- QSX11.9 Series: QSX11.9 CM2250 ECF

- QSZ13 Series: QSZ13 CM2150 Z102

Each of these engines relies on the Water Bypass Tube to maintain the correct coolant flow, preventing overheating and ensuring the engine operates within its optimal temperature range. Proper installation of this part is crucial for the longevity and efficiency of the engine.

Role of Part 2883347 Water Bypass Tube in Engine Systems

The Water Bypass Tube, identified by part number 2883347, is an essential component in the thermal management system of an engine. It facilitates the circulation of coolant in scenarios where the thermostat restricts coolant flow.

When the engine is cold, the thermostat remains closed, preventing coolant from entering the radiator. During this phase, the Water Bypass Tube allows coolant to circulate within the engine block and cylinder head, ensuring that these critical components receive adequate cooling before the thermostat opens.

Once the engine reaches its operating temperature, the thermostat opens, allowing coolant to flow through the radiator for further cooling. The Water Bypass Tube continues to play a role by providing an alternative path for coolant, balancing the flow and maintaining consistent engine temperature.

Conclusion

The Cummins water bypass tube part #2883347 is an essential component in maintaining the efficiency and reliability of commercial truck engines. By understanding its function, importance, and maintenance requirements, engineers, mechanics, and fleet operators can ensure their trucks perform optimally and avoid costly breakdowns. Regular maintenance and prompt troubleshooting are key to maximizing the lifespan and performance of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.