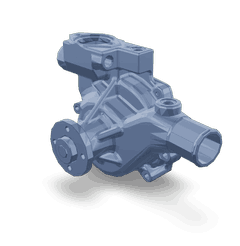

The Cummins 5311736 Water Pump is a component designed for use in commercial trucks. Its purpose is to circulate coolant through the engine to maintain optimal operating temperatures. This part is integral to the engine’s cooling system, ensuring that the engine operates within specified temperature ranges to prevent overheating and maintain efficiency.

Basic Concepts of Water Pumps

Water pumps operate on the principle of fluid dynamics, using mechanical energy to move coolant through the engine’s cooling system. They consist of an impeller driven by a shaft, which rotates to create centrifugal force, pushing coolant outward and through the system. The significance of water pumps in engine cooling systems lies in their ability to regulate engine temperature, which is vital for engine performance and longevity 1.

Purpose of the Cummins 5311736 Water Pump

This Cummins part plays a role in the cooling system of a truck engine by circulating coolant from the radiator through the engine block and back. This circulation helps in dissipating heat generated by the engine’s operation, maintaining optimal engine temperature. Proper temperature regulation is key to ensuring engine components do not overheat, which could lead to reduced efficiency, increased wear, and potential engine damage.

Key Features

The 5311736 is characterized by its robust design and the use of high-quality materials. It features a durable housing, often made from cast iron or aluminum, and a precision-machined impeller. These attributes contribute to the pump’s performance and durability, allowing it to withstand the demanding conditions of commercial truck operations. Additionally, the pump may include seals and gaskets designed to prevent leaks and ensure efficient operation.

Benefits

The advantages provided by the 5311736 include enhanced engine efficiency, reliability, and longevity. By ensuring effective coolant circulation, the pump helps maintain engine temperature within optimal ranges, which can lead to improved fuel efficiency and reduced wear on engine components. For fleet operators, this translates to lower maintenance costs and increased uptime, contributing to overall cost savings.

Installation and Compatibility

Proper installation of this part is crucial for its effective operation. Installation procedures may vary depending on the specific truck model and engine type, but generally involve securing the pump to the engine, connecting it to the coolant system, and ensuring all connections are tight and leak-free. Compatibility with various truck models and engine types is an important consideration, ensuring the pump meets the specific requirements of the application.

Maintenance and Troubleshooting

Routine maintenance practices for the 5311736 include regular inspection for leaks, wear, or damage, and ensuring all connections are secure. Troubleshooting common issues such as leaks, noise, or decreased efficiency may involve checking for worn seals or gaskets, ensuring the impeller is not obstructed, and verifying that the pump is receiving adequate power. Regular maintenance and prompt attention to issues can help ensure the pump’s optimal performance and longevity.

Performance and Efficiency

The performance characteristics and efficiency of the 5311736 are influenced by its design and construction. Effective coolant circulation contributes to engine cooling effectiveness, which is vital for overall truck performance. The pump’s ability to maintain optimal engine temperature under varying operating conditions is a testament to its performance and efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a reputation for quality, Cummins is committed to manufacturing high-quality automotive components that meet the demanding requirements of commercial and industrial applications. The company’s focus on reliability, performance, and customer satisfaction underscores its position as a leader in the industry.

Cummins Water Pump 5311736 Compatibility

The Water Pump part number 5311736 is designed to fit seamlessly with a variety of engine models, ensuring optimal cooling and performance. This water pump is engineered to maintain the engine’s temperature within the optimal range, preventing overheating and ensuring longevity.

B3.3 Engine

The B3.3 engine, a part of the Cummins engine family, is compatible with the 5311736 water pump. This engine is known for its reliability and efficiency, making it a popular choice in various applications. The water pump’s design ensures it fits perfectly with the B3.3 engine, providing efficient coolant circulation and maintaining the engine’s operational temperature.

Grouping of Compatible Engines

In addition to the B3.3 engine, the 5311736 water pump is also compatible with other models within the Cummins engine range. These engines share similar design features and requirements, ensuring that the water pump fits and functions effectively across the board. The compatibility extends to various applications, from industrial machinery to agricultural equipment, ensuring that the water pump meets the demands of different operational environments.

The 5311736 water pump’s design includes precision-engineered components that ensure a secure fit and reliable performance. The pump’s material and construction are chosen to withstand the rigors of continuous operation, providing durability and consistent performance over time.

Role of Part 5311736 Water Pump in Engine Systems

The part 5311736 water pump is an essential component in the cooling system of an engine, ensuring that the engine operates within optimal temperature ranges. It is responsible for circulating coolant throughout the engine and radiator, thereby preventing overheating.

Integration with Engine Components

-

Thermostat Housing: The water pump connects to the thermostat housing, which regulates the flow of coolant based on engine temperature. When the engine is cold, the thermostat remains closed, directing coolant back to the water pump to recirculate within the engine block. As the engine warms up, the thermostat opens, allowing coolant to flow to the radiator for cooling.

-

Radiator: Coolant from the water pump flows into the radiator, where it is cooled by ambient air, often assisted by a fan. The cooled coolant then returns to the water pump to continue the cycle.

-

Engine Block: The water pump pushes coolant through passages within the engine block, absorbing heat generated by combustion. This helps maintain consistent engine temperature and prevents damage from overheating.

-

Heater Core: In many systems, a portion of the coolant circulated by the water pump is directed to the heater core, providing warmth to the vehicle’s interior. This connection ensures that the cabin remains comfortable in cold weather.

-

Water Pump Pulley: Driven by the engine’s serpentine belt, the water pump pulley transfers rotational energy to the water pump impeller, enabling it to move coolant through the system.

-

Coolant Hoses: The water pump is connected to various coolant hoses that transport coolant to and from different components, including the radiator, heater core, and engine block.

-

Bypass Valve: Some systems include a bypass valve that allows coolant to circumvent the thermostat when it is closed. This ensures continuous circulation of coolant, even when the thermostat is not yet open.

In summary, the part 5311736 water pump plays a significant role in maintaining the thermal efficiency of the engine by ensuring consistent coolant circulation through critical components.

Conclusion

The Cummins 5311736 Water Pump is a vital component in the cooling system of commercial trucks, ensuring optimal engine temperature and performance. Its robust design, compatibility with various engine models, and the benefits it offers in terms of engine efficiency and longevity make it a valuable asset for fleet operators. Proper installation, maintenance, and understanding of its role within the engine system are crucial for maximizing its performance and durability.

-

Modern Diesel Technology: Heavy Equipment Systems, Robert Huzij, Angelo Spano, Sean Bennett, Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.