This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4349731 Water Pump Impeller is a component designed to facilitate the efficient operation of the cooling system in heavy-duty trucks. Its purpose is to circulate coolant through the engine, ensuring that the temperature remains within optimal ranges for performance and longevity. The significance of this part lies in its ability to maintain engine temperature, which is vital for the overall efficiency and reliability of the vehicle.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump that moves coolant through the engine’s cooling system. It operates on the principles of centrifugal force and fluid dynamics. As the impeller spins, it creates a centrifugal force that pushes the coolant outward, generating flow through the system. This continuous circulation helps dissipate heat from the engine, maintaining its operational temperature 1.

Role of the 4349731 Water Pump Impeller in Truck Operation

The 4349731 Water Pump Impeller plays a role in maintaining engine temperature by ensuring a consistent flow of coolant. This consistent flow is crucial for preventing overheating, which can lead to engine damage. By efficiently circulating coolant, the impeller helps to sustain the engine’s performance under various operating conditions, contributing to the truck’s overall reliability 2.

Key Features of the 4349731 Water Pump Impeller

The design of the 4349731 Water Pump Impeller incorporates materials and construction techniques that enhance its performance and durability. It is crafted from high-quality materials that resist wear and corrosion, ensuring longevity. The impeller’s design allows for efficient coolant flow, which is critical for effective engine cooling. Additionally, its construction is tailored to withstand the demanding conditions typical of heavy-duty truck operations 3.

Benefits of Using the 4349731 Water Pump Impeller

Utilizing the 4349731 Water Pump Impeller offers several advantages. It provides improved cooling efficiency, which is beneficial for maintaining engine temperature within optimal ranges. The impeller’s durable construction ensures longevity, reducing the frequency of replacements. Its reliable performance under demanding conditions makes it a valuable component for heavy-duty applications 4.

Installation and Compatibility

Proper installation of the 4349731 Water Pump Impeller is important for ensuring its effective operation. Specific guidelines should be followed to integrate the impeller with the truck’s cooling system. Considerations for different truck models may include ensuring compatibility with the existing water pump and coolant system to achieve optimal performance 5.

Maintenance and Troubleshooting

Regular maintenance practices for the 4349731 Water Pump Impeller include inspecting for signs of wear or failure, such as leaks or unusual noises. Troubleshooting common issues may involve checking the impeller’s alignment and ensuring there are no obstructions in the coolant flow. Adhering to maintenance schedules can help prevent unexpected failures and extend the component’s service life.

Performance Under Various Conditions

The 4349731 Water Pump Impeller is designed to perform effectively in a range of operating environments. Whether facing extreme temperatures or heavy-duty applications, the impeller’s robust design and materials allow it to maintain efficient coolant circulation. This ensures that the engine remains cool, even under challenging conditions, contributing to the truck’s reliability and performance.

Comparison with Other Water Pump Impellers

When compared to similar components from other manufacturers, the 4349731 Water Pump Impeller stands out for its design, performance, and durability. Differences may include the materials used, the efficiency of coolant flow, and the impeller’s resistance to wear and corrosion. These factors contribute to its effectiveness in heavy-duty truck applications.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its wide range of products and strong reputation. With a history of innovation and quality, Cummins has become a trusted name for those in need of reliable and high-performance engine components. The company’s commitment to excellence is reflected in its product offerings, including the 4349731 Water Pump Impeller.

Water Pump Impeller Part 4349731 Compatibility with Cummins Engines

The Water Pump Impeller part number 4349731, manufactured by Cummins, is a critical component designed to ensure efficient coolant circulation within the engine. This part is compatible with several Cummins engine models, including the QSK95 CM2350 K111 and QSK95 CM2350 K113.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the water pump impeller is engineered to fit seamlessly into the engine’s water pump assembly. This ensures that the impeller can effectively move coolant through the engine’s cooling system, maintaining optimal operating temperatures and preventing overheating.

The design of the impeller is such that it can handle the specific flow rates and pressures required by these engines, ensuring that the cooling system operates efficiently under various conditions. The compatibility of part 4349731 with these engines underscores its importance in maintaining the engine’s performance and longevity.

Role of Part 4349731 Water Pump Impeller in Engine Systems

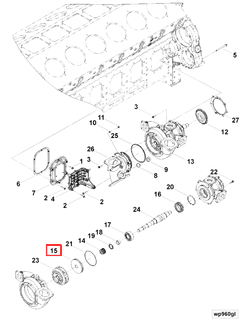

The part 4349731 Water Pump Impeller is an essential component within the water pump assembly, facilitating efficient coolant circulation throughout the engine system. When integrated into the water pump, the impeller works in tandem with the pump housing and the drive mechanism to ensure optimal performance.

Interaction with the Water Pump

Within the water pump, the impeller is mounted on the pump shaft. As the engine operates, the shaft rotates, causing the impeller blades to spin. This rotation generates centrifugal force, which propels coolant from the pump’s center outward through the pump housing. The consistent movement of coolant is vital for maintaining engine temperature within safe operating limits.

Contribution to the Water Pump Kit

In a water pump kit, the impeller is often included as a replacement part. When the water pump requires servicing, the impeller may need to be replaced to ensure the pump operates efficiently. The impeller’s design and material are selected to withstand the pressures and temperatures within the engine cooling system, providing reliable performance over time.

Ensuring Efficient Coolant Flow

The effectiveness of the impeller directly influences the coolant flow rate. A well-functioning impeller ensures that coolant is circulated rapidly and evenly throughout the engine block and cylinder head. This consistent flow helps in dissipating heat generated by combustion, preventing overheating and potential engine damage.

Integration with the Overall Cooling System

Beyond the water pump, the impeller’s role extends to the entire cooling system. Efficient impeller operation contributes to the stability of the thermostat’s function, ensuring it opens and closes at the correct temperatures. This, in turn, maintains the engine’s optimal operating temperature, enhancing overall engine performance and longevity.

Conclusion

The Cummins 4349731 Water Pump Impeller is a critical component in the cooling systems of heavy-duty trucks, ensuring efficient coolant circulation and maintaining optimal engine temperatures. Its robust design, durable materials, and compatibility with various Cummins engines make it a reliable choice for demanding applications. Regular maintenance and proper installation are key to maximizing its performance and longevity.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L123B Transit Bus Applications. Bulletin Number 5411467.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.