This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

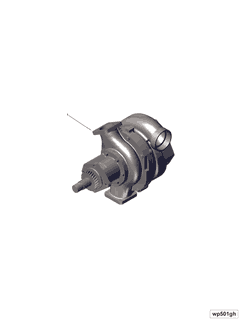

The Cummins 3602788 Water Pump Impeller is a component designed for use in the cooling systems of heavy-duty trucks. Manufactured by Cummins Inc., a leader in the production of diesel engines and related components, this impeller is integral to maintaining optimal engine temperatures. Its role in the cooling system ensures that the engine operates within safe temperature ranges, thereby contributing to the overall efficiency and longevity of the truck’s engine 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump of an engine’s cooling system. Its function is to move coolant through the system by leveraging the principles of centrifugal force and fluid dynamics. As the impeller spins, it creates a centrifugal force that pushes the coolant outward, facilitating its movement through the engine block, radiator, and back to the pump. This continuous circulation helps dissipate heat generated by the engine, maintaining its operating temperature within a specified range 2.

Purpose of the 3602788 Water Pump Impeller

This part plays a role in the operation of a truck’s engine cooling system by ensuring the efficient movement of coolant. It is designed to work in conjunction with the water pump to circulate coolant through the engine, absorbing heat and transferring it to the radiator where it is dissipated. This process is vital for preventing engine overheating, which can lead to reduced performance and potential damage 3.

Key Features

The design and construction of the 3602788 incorporate several features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding environments. The blade configuration is optimized for efficient coolant flow, and the impeller may include unique attributes such as a balanced design to reduce vibration and noise during operation 4.

Benefits

The advantages provided by this Cummins part include improved coolant flow and enhanced engine cooling efficiency. By ensuring consistent and efficient coolant circulation, it contributes to maintaining optimal engine temperatures. This not only supports engine performance but also potentially extends engine longevity by reducing the risk of overheating-related damage.

Installation and Compatibility

Proper installation of the 3602788 is crucial for ensuring its effective operation within the engine cooling system. Installation procedures may vary depending on the specific engine model, but generally involve securing the impeller within the water pump housing and ensuring it is properly aligned with the pump shaft. Compatibility with various Cummins engine models is an important consideration, ensuring that the impeller fits and functions correctly within the intended application.

Maintenance and Troubleshooting

Maintaining the 3602788 involves regular inspection for signs of wear or damage, such as corrosion on the blades or shaft. Routine checks can help identify issues before they lead to more significant problems, such as leaks or reduced cooling efficiency. Troubleshooting common issues may involve inspecting the impeller for proper alignment, ensuring there are no obstructions in the coolant flow path, and checking for signs of wear that may indicate the need for replacement.

Performance Enhancements

For those looking to further improve engine cooling performance, there are potential upgrades or modifications that can be made to the cooling system. These may include the installation of aftermarket impellers designed for increased flow rates or system enhancements such as upgraded radiators or additional cooling fans. These modifications can contribute to more efficient heat dissipation, supporting engine performance under demanding conditions.

Common Failure Modes

Water pump impellers, including the 3602788 model, can experience several typical failure modes. These include corrosion, which can degrade the impeller’s material over time, erosion caused by the continuous flow of coolant, and mechanical wear from the impeller’s rotation. These failure modes can impact the engine cooling system’s performance, potentially leading to overheating if not addressed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the heavy-duty truck industry, Cummins is known for its commitment to quality and innovation in engine components. The company’s extensive product range and focus on customer satisfaction underscore its position as a trusted provider of engine parts and solutions.

Water Pump Impeller (Part 3602788) Compatibility with Cummins Engines

The Water Pump Impeller (Part 3602788) manufactured by Cummins is designed to fit seamlessly with several of their engine models. This part is integral to the cooling system, ensuring efficient heat dissipation and maintaining optimal engine temperature. Below is a detailed description of its compatibility with specific Cummins engines.

N14 G and N14 MECHANICAL Engines

The Water Pump Impeller (Part 3602788) is specifically engineered to fit both the N14 G and N14 MECHANICAL engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The impeller’s design ensures that it can handle the high-pressure requirements of these engines, providing consistent and reliable cooling.

NH/NT 855 Engines

Similarly, the Water Pump Impeller (Part 3602788) is also compatible with the NH/NT 855 engines. These engines are part of Cummins’ lineup of mid-range power units, offering a balance of power and efficiency. The impeller’s precision engineering ensures it can efficiently circulate coolant, contributing to the overall longevity and performance of the engine.

Role of Part 3602788 Water Pump Impeller in Engine Systems

The 3602788 is an essential component within various engine systems, particularly those involving water pumps. Its primary function is to facilitate the efficient transfer of coolant throughout the engine system, ensuring optimal thermal management.

Integration with Water Pump Components

When installed in a Water Pump, the impeller works in conjunction with the pump housing and seals to create a pressurized flow of coolant. This flow is directed through the Water Pump Kit, which typically includes the pump, gaskets, and other necessary components to ensure a leak-free system.

Role in Engine Kit and On-Board Spares

In an Engine Kit, the impeller is a key element that ensures the water pump operates effectively. This is particularly important in kits designed for high-performance engines where thermal management is paramount. Similarly, in On-Board Spares and Kit On Board Spares, the impeller is often included to allow for quick replacements in the field, maintaining the engine’s cooling efficiency without downtime.

Function within Water Pump Repair Kit

In a Water Pump Repair Kit, the impeller is frequently replaced to restore the pump’s functionality. Worn or damaged impellers can lead to inefficient coolant flow, potentially causing engine overheating. Therefore, ensuring the impeller is in good condition is vital for the kit’s overall effectiveness.

Interaction with Water and Idler Pump

In systems utilizing a Water and Idler Pump, the impeller’s role extends to managing the flow of coolant while also accommodating the mechanical demands of the idler function. This dual-purpose setup requires the impeller to be robust and precisely engineered to handle both cooling and mechanical tasks efficiently.

Importance in Thermal Management

Overall, the 3602788 is integral to the thermal management of engine systems. Its efficient design and reliable performance are key to maintaining engine health and ensuring consistent operation under various conditions.

Conclusion

The Cummins 3602788 Water Pump Impeller is a critical component for maintaining the cooling systems of heavy-duty trucks. Its efficient design, compatibility with various Cummins engines, and role in thermal management contribute to the overall performance and longevity of the engine. Proper installation, maintenance, and understanding of its function within engine systems are essential for maximizing its benefits and ensuring optimal engine operation.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Quigley, J.M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.