This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3412924 Water Pump Pulley is a critical component within the engine cooling system of commercial trucks. It facilitates the operation of the water pump, ensuring coolant circulates effectively to maintain optimal engine temperatures. This part’s significance is underscored by its role in the efficient and reliable performance of the engine cooling system, which is essential for the truck’s operation and longevity 1.

Basic Concepts of Water Pump Pulleys

A water pump pulley connects the engine’s crankshaft to the water pump, transferring rotational force to enable coolant circulation. This process is vital for dissipating heat generated during engine operation, preventing overheating and potential damage. The pulley is part of the engine’s belt system, which also drives auxiliary components like the alternator and power steering pump 2.

Purpose of the Cummins 3412924 Water Pump Pulley

This Cummins part drives the water pump to circulate coolant, maintaining the engine’s temperature within a safe range. Its design and construction are tailored to withstand the demands of heavy-duty truck engines, ensuring reliable performance under various operating conditions 3.

Key Features

The Cummins 3412924 Water Pump Pulley features robust material construction, typically involving high-strength alloys or composites, offering resistance to wear and corrosion. Its design elements, such as groove pattern and balance, are optimized for efficient belt engagement and minimal vibration. Additional features may include a corrosion-resistant coating or specific geometry to enhance performance in demanding environments 4.

Benefits

This part offers improved engine cooling efficiency, reliable operation under heavy-duty conditions, and compatibility with Cummins engines. Its design ensures consistent coolant circulation and engine temperature regulation, contributing to optimal performance and longevity in Cummins-powered trucks.

Installation and Compatibility

Proper installation of the Cummins 3412924 Water Pump Pulley is crucial for optimal performance and compatibility with Cummins engines. Installation guidelines include aligning the pulley with the water pump and securing it with appropriate fasteners. Ensuring alignment with the engine’s belt system prevents belt slippage or damage. Compatibility is ensured through design and engineering standards that meet manufacturer specifications.

Maintenance and Troubleshooting

Maintaining the Cummins 3412924 Water Pump Pulley involves regular inspections for signs of wear or damage, such as cracks, corrosion, or excessive belt wear. Troubleshooting common issues like belt slippage or pulley misalignment involves identifying the root cause and taking corrective action, which may include adjusting belt tension or replacing worn components.

Performance Enhancements

Exploring performance enhancements for the Cummins 3412924 Water Pump Pulley may involve considering aftermarket options or modifications. These could include pulleys with improved materials or designs for increased durability or efficiency. Upgrading to a pulley with a more aggressive groove pattern can enhance belt grip and reduce slippage under high-load conditions, contributing to improved engine cooling performance and system reliability.

Cummins Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With over a century of history, Cummins has established a reputation for high-quality components for commercial vehicles. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the automotive industry, providing reliable and efficient solutions for various applications.

Role of Part 3412924 Water Pump Pulley in Engine Systems

The Part 3412924 Water Pump Pulley is integral to the efficient operation of various engine systems, particularly those involving the water pump. It ensures optimal coolant circulation, maintaining engine temperature within safe operating limits.

Integration with the Water Pump

When the engine is running, the water pump pulley is driven by the engine’s crankshaft via a belt. This connection allows the pulley to transfer rotational force to the water pump impeller, creating a flow of coolant that is circulated through the engine block, cylinder head, and other critical components to absorb heat. The consistent operation of the water pump pulley ensures effective coolant distribution, preventing overheating and potential engine damage.

Function in Water and Idler Pump Systems

In systems with both water and idler pumps, the water pump pulley plays a dual role. It drives the water pump to circulate coolant and interacts with the idler pulley to maintain proper belt tension. This tension is vital for the efficient transfer of power from the crankshaft to the water pump, ensuring smooth operation and reducing the risk of belt slippage or failure.

Role in Water Pump Kits

Water pump kits often include the water pump pulley as a key component. These kits are designed to provide a comprehensive solution for replacing a failing water pump. The pulley included in these kits is engineered to match the specifications of the original equipment, ensuring a seamless fit and function. By incorporating the water pump pulley into the kit, mechanics can perform a more thorough and reliable repair, enhancing the overall performance and longevity of the engine’s cooling system.

Conclusion

The Cummins 3412924 Water Pump Pulley is a vital component in the engine cooling system of commercial trucks. Its design and features ensure reliable operation, efficient coolant circulation, and compatibility with Cummins engines. Proper installation, maintenance, and potential performance enhancements contribute to the overall efficiency and longevity of the engine’s cooling system.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Reif, K. Ed. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

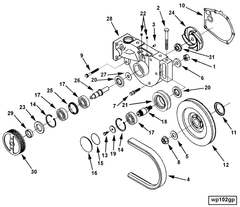

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Wear Sleeve | 1 | 203097 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.