This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

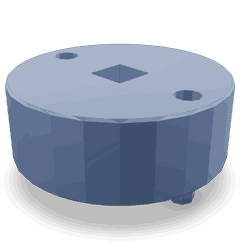

The Water Pump Impeller Replacer (Part #3165124) by Cummins is a specialized component designed for the maintenance of heavy-duty trucks. This Cummins part is integral to the cooling system, ensuring that the engine operates within optimal temperature ranges. Its role is significant in preventing engine overheating, which can lead to severe damage and reduced efficiency 1.

Basic Concepts

Water pump impellers are vital components within the cooling system of a truck engine. They function by circulating coolant through the engine block and radiator. The impeller, a rotating component within the water pump, creates the necessary flow of coolant to absorb heat from the engine and dissipate it through the radiator. This process is fundamental to maintaining engine temperature and ensuring efficient operation 2.

Purpose and Function

The Water Pump Impeller Replacer plays a role in the operation of a truck by facilitating the replacement of worn or damaged impellers. It aids in maintaining efficient coolant flow, which is crucial for engine cooling. By ensuring that the impeller is in good condition, the replacer helps to sustain the cooling system’s effectiveness, thereby contributing to the overall performance and longevity of the engine 3.

Key Features

The Water Pump Impeller Replacer is characterized by its robust design and the use of high-quality materials. These features enhance its durability and performance. The replacer is engineered to fit precisely within the water pump, ensuring a secure and efficient replacement process. Additionally, it may include unique attributes such as corrosion-resistant coatings or advanced sealing mechanisms to improve its functionality.

Benefits

Using the Water Pump Impeller Replacer offers several advantages. It contributes to improved engine cooling efficiency by ensuring that the impeller functions optimally. This can lead to enhanced engine performance and reduced risk of overheating. Furthermore, the replacer can extend the longevity of the cooling system components and may result in potential cost savings by preventing more extensive engine damage.

Installation Process

Installing the Water Pump Impeller Replacer involves several steps to ensure proper fitting and function. Begin by draining the coolant system to prevent spills and ensure a clean working environment. Remove the old impeller, taking care to note its orientation and condition. Install the replacer according to the manufacturer’s instructions, ensuring it is securely in place. Refill the coolant system and check for leaks. It is important to follow best practices, such as using the correct tools and torque specifications, to avoid common pitfalls like improper seating or damage to the impeller.

Troubleshooting and Maintenance

To diagnose common issues related to water pump impellers, regularly inspect the impeller for signs of wear, corrosion, or damage. Ensure that the coolant system is free of debris and that the coolant level is adequate. Maintenance practices such as periodic inspection and cleaning of the impeller can help ensure the longevity and efficiency of the replacer. Additionally, monitoring the engine temperature can provide early indications of potential issues within the cooling system.

Common Failures and Solutions

Typical failure modes for water pump impellers include wear, corrosion, and damage from debris within the coolant system. Solutions to these issues involve regular inspection and maintenance, as well as the use of high-quality replacement parts like the Water Pump Impeller Replacer. Preventive measures include ensuring the coolant system is clean, using the correct type of coolant, and adhering to recommended maintenance schedules.

Manufacturer Information

Cummins is a renowned manufacturer with a rich history in diesel engine production. The company is known for its expertise in engine technology and commitment to quality and innovation. Cummins’ automotive components, including the Water Pump Impeller Replacer, are designed with precision and reliability in mind, reflecting the brand’s dedication to excellence in the industry.

Conclusion

The 3165124 Water Pump Impeller Replacer is a critical component for maintaining the efficiency and reliability of heavy-duty truck engines. By ensuring optimal coolant flow and preventing engine overheating, this part contributes to the overall performance and longevity of the engine. Regular maintenance and the use of high-quality replacement parts are essential for sustaining the cooling system’s effectiveness.

-

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.