This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

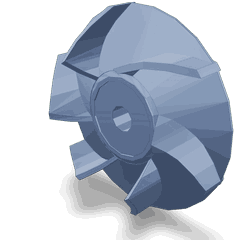

The Cummins 3102723 Water Pump Impeller is a component designed to facilitate the efficient operation of the cooling system in heavy-duty trucks. Its purpose is to circulate coolant through the engine, ensuring that the engine maintains an optimal operating temperature. This component is significant in the cooling system as it directly influences the engine’s performance and longevity by preventing overheating 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump that moves coolant through the engine’s cooling system. It functions by creating centrifugal force as it spins, which pushes coolant out of the pump and into the engine’s passages. This circulation is vital for dissipating heat generated by the engine, thereby maintaining a stable operating temperature 2. The impeller’s efficiency in this process is crucial for the overall health and performance of the engine.

Role of the 3102723 Water Pump Impeller in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring that coolant is effectively circulated through the engine. This circulation helps in dissipating heat, which is generated as a byproduct of the combustion process. By maintaining a consistent coolant flow, the impeller contributes to the engine’s efficiency and performance, ensuring that the engine operates within its designed temperature range 3.

Key Features of the 3102723 Water Pump Impeller

The 3102723 is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures encountered in heavy-duty truck engines. The impeller’s design includes features that enhance its performance and durability, such as precise blade angles and a balanced structure to minimize vibration and wear.

Benefits of Using the 3102723 Water Pump Impeller

Utilizing this part offers several benefits. It contributes to improved cooling efficiency, which is crucial for preventing engine overheating. Additionally, its durable construction and efficient design help in reducing the risk of coolant leaks and system failures. Over time, this can lead to enhanced engine longevity and reliability.

Troubleshooting Common Issues with Water Pump Impellers

Common issues with water pump impellers may include leaks, unusual noise, or decreased performance. These issues can often be traced back to wear and tear, improper installation, or contamination within the cooling system. Addressing these problems may involve inspecting the impeller for damage, ensuring proper installation, and maintaining the cleanliness of the cooling system to prevent debris from affecting the impeller’s operation.

Maintenance Tips for Water Pump Impellers

To ensure the longevity and optimal performance of water pump impellers, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the impeller and its housing to remove any buildup, and following manufacturer guidelines for replacement intervals. Proper maintenance helps in identifying potential issues before they lead to significant problems, ensuring the cooling system operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s commitment to quality and performance is evident in its product offerings, including the 3102723, which is designed to meet the demanding requirements of heavy-duty applications.

Compatibility of Water Pump Impeller Part 3102723 with Cummins Engines

The Water Pump Impeller part number 3102723, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the cooling system’s efficiency and ensuring the engine operates within its optimal temperature range.

ISM CM570/870 and ISM CM876

The ISM CM570/870 and ISM CM876 engines are part of Cummins’ lineup of industrial and marine engines. The Water Pump Impeller part 3102723 is engineered to fit these models, ensuring that the cooling system functions correctly. This compatibility is vital for maintaining the engine’s performance and longevity.

ISM11 CM876 SN and QSM11 CM876

The ISM11 CM876 SN and QSM11 CM876 engines are another set of Cummins engines that benefit from the Water Pump Impeller part 3102723. This part is specifically designed to fit these models, ensuring that the cooling system operates efficiently. The impeller’s design allows for effective coolant circulation, which is essential for preventing engine overheating and maintaining optimal performance.

By ensuring that the Water Pump Impeller part 3102723 is compatible with these engines, Cummins guarantees that the cooling system will function as intended, contributing to the overall reliability and efficiency of the engine.

Understanding the Integration of Part 3102723 Water Pump Impeller in Engine Systems

The part 3102723 is a fundamental component in the arrangement of various engine systems, specifically within the water pump assembly. Its role is to facilitate the efficient circulation of coolant throughout the engine, ensuring optimal thermal management.

Role in Water Pump Assembly

Within the water pump, the impeller is responsible for generating the necessary force to move coolant from the pump to the engine’s various components. This movement is essential for dissipating heat generated during engine operation. The impeller’s design allows it to create a centrifugal force, which propels the coolant through the system.

Interaction with Water Pump Kit

When integrated into a water pump kit, the impeller works in conjunction with other components such as the pump housing, gaskets, and seals. The kit often includes a top-level assembly pump, which houses the impeller. This assembly ensures that the impeller is correctly positioned and sealed, preventing coolant leaks and maintaining system pressure.

Contribution to Water Top-Level Assembly Pump

In the water top-level assembly pump, the impeller is a key element. It is typically mounted on a shaft that is driven by the engine’s camshaft or a dedicated drive mechanism. As the shaft rotates, the impeller spins, creating a flow of coolant. This flow is directed through passages in the pump housing and into the engine’s cooling circuits.

Ensuring Efficient Coolant Circulation

The efficient operation of the impeller is vital for maintaining the engine’s temperature within safe operating ranges. By ensuring consistent coolant circulation, the impeller helps prevent overheating, which can lead to engine damage. The design of the impeller, with its precise blade angles and material properties, is optimized to handle the viscosity and flow characteristics of the coolant.

Integration with Engine Cooling System

The impeller’s function extends beyond the water pump itself. It interacts with the broader engine cooling system, including the radiator, thermostat, and hoses. The consistent flow of coolant it generates allows these components to effectively manage the engine’s thermal load. The impeller’s performance directly influences the efficiency of heat exchange in the radiator and the overall stability of the engine’s operating temperature.

Conclusion

In summary, the part 3102723 plays a significant role in the engine’s cooling system by ensuring the efficient circulation of coolant. Its integration with the water pump, water pump kit, and top-level assembly pump is essential for maintaining engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.