This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3040909 Water Pump Impeller is a critical component designed to facilitate the efficient operation of the cooling system in heavy-duty trucks. Its primary function is to circulate coolant through the engine, ensuring that the engine maintains an optimal operating temperature. This component significantly influences the engine’s performance and longevity by managing thermal conditions 1.

Basic Concepts of Water Pump Impellers

A water pump impeller is a rotating component within the water pump that moves coolant through the engine’s cooling system. It operates by creating centrifugal force as it spins, which propels the coolant from the center of the impeller outwards through the cooling passages. This process is vital for dissipating heat generated by the engine, thus maintaining engine temperature within specified limits and preventing overheating 2.

Role of the 3040909 Water Pump Impeller in Truck Operation

The 3040909 Water Pump Impeller ensures that coolant is effectively circulated through the engine. This circulation is essential for absorbing heat from the engine components and transferring it to the radiator, where it is dissipated into the atmosphere. The efficient operation of this impeller contributes to the overall efficiency and performance of the engine cooling system, helping to maintain engine reliability and efficiency under various operating conditions.

Key Features of the 3040909 Water Pump Impeller

The 3040909 is characterized by its robust design and the materials used in its construction. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine cooling system. Unique characteristics of this impeller may include a specific blade design that enhances coolant flow and reduces the likelihood of cavitation, as well as a balance that ensures smooth operation and minimizes wear on the water pump components.

Benefits of Using the 3040909 Water Pump Impeller

Using this Cummins part offers several benefits, including improved cooling efficiency due to its design and material properties. Its durability ensures long-term reliability, reducing the frequency of replacements and maintenance. Additionally, the impeller’s efficient design contributes to the overall reliability of the engine cooling system, helping to prevent overheating and associated engine damage.

Installation Process

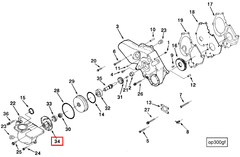

Installing the 3040909 involves several steps to ensure proper function and integration within the cooling system. The process requires specific tools and equipment, and it is important to follow manufacturer guidelines for installation to ensure compatibility and effectiveness. Key considerations include proper alignment within the water pump housing, secure fastening to prevent movement, and ensuring that all seals are intact to prevent coolant leaks.

Common Issues and Troubleshooting

Common issues with the 3040909 may include wear and tear leading to reduced efficiency, leaks due to damaged seals, or cavitation caused by air pockets in the coolant. Troubleshooting these issues involves inspecting the impeller for signs of damage, ensuring that all connections are secure, and checking the coolant system for proper fluid levels and absence of air pockets. Solutions may range from simple adjustments to replacement of the impeller or associated components.

Maintenance Tips

To ensure the longevity and optimal performance of the 3040909, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning the impeller and surrounding components to remove any buildup that could impede coolant flow, and following manufacturer guidelines for replacement intervals. Additionally, maintaining the correct coolant level and quality is crucial for the efficient operation of the impeller and the cooling system as a whole.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, emphasizing performance, durability, and efficiency.

Role of Part 3040909 Water Pump Impeller in Engine Systems

The part 3040909 is an essential component within the cooling system of an engine, working in concert with other parts to maintain optimal engine temperature.

When the engine operates, it generates a significant amount of heat. The Water Pump Impeller, housed within the water pump assembly, plays a pivotal role in circulating coolant throughout the engine system. This circulation begins at the water pump, where the impeller draws coolant from the oil pan. The oil pan, often located at the engine’s base, serves as a reservoir for the coolant.

As the Water Pump Impeller rotates, it creates a centrifugal force that propels the coolant through the engine’s passages. This movement ensures that the coolant absorbs heat from the engine’s components, such as the cylinder heads and engine block.

The Water Pump Mounting is the structural component that secures the water pump to the engine. It ensures that the water pump, and by extension the impeller, remains in the correct position and operates efficiently. Proper mounting is essential for the impeller to function correctly, as any misalignment could lead to inefficient coolant flow.

Conclusion

In summary, the part 3040909, in conjunction with the oil pan and water pump mounting, ensures effective coolant circulation. This circulation is vital for dissipating heat, protecting engine components from overheating, and maintaining the engine’s overall efficiency and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.