4944257

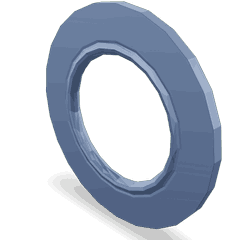

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4944257 Sealing Washer is a component designed for use in commercial truck operations. Its purpose is to provide a reliable seal in various mechanical systems, ensuring the efficient operation of the truck’s components. This part is integral to maintaining the integrity of fluid systems within the truck, contributing to overall performance and longevity.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, preventing the leakage of fluids or gases. They function by filling the gap between mating surfaces, ensuring that the system remains closed and operates efficiently. Sealing washers are constructed from a variety of materials, including rubber, metal, and composite materials, depending on the specific requirements of the application and the environment in which they operate. These materials are chosen for their ability to withstand pressure, temperature variations, and chemical exposure, ensuring durability and reliability in demanding conditions 1.

Role of the 4944257 Sealing Washer in Truck Operations

The Cummins 4944257 Sealing Washer plays a specific role in the operation of commercial trucks by ensuring the integrity of seals in various systems. It is associated with components such as fuel injectors, where it helps maintain the seal around the injector body, preventing fuel leakage and ensuring efficient fuel delivery. By contributing to the efficient functioning of these systems, the sealing washer helps maintain the truck’s performance and reliability 2.

Key Features

The Cummins 4944257 Sealing Washer is characterized by its design and material composition, which are tailored to meet the demands of commercial truck operations. It is made from materials that offer excellent resistance to wear, pressure, and chemical exposure, ensuring durability and reliability. The design of the washer allows it to fit precisely within the system it is intended for, providing a secure and effective seal. Additionally, any unique attributes that enhance its performance and durability, such as special coatings or reinforcements, contribute to its effectiveness in demanding applications 3.

Benefits

The use of the Cummins 4944257 Sealing Washer offers several benefits, including improved system efficiency through reliable sealing, reduced maintenance requirements due to its durability, and enhanced reliability of the truck’s components. By ensuring that seals remain intact, the washer contributes to the overall performance and longevity of the truck, reducing the likelihood of system failures and the need for frequent repairs.

Troubleshooting and Maintenance

Common issues associated with sealing washers include wear, damage, and failure to create an effective seal. Troubleshooting these problems involves inspecting the washer for signs of wear or damage and ensuring that it is correctly installed. Maintenance practices to ensure the longevity and effectiveness of the Cummins 4944257 Sealing Washer include regular inspection and replacement as needed, as well as ensuring that the surfaces it seals are clean and free from debris. Proper installation and handling are also crucial to maintaining the washer’s effectiveness.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, which are designed to meet the demanding requirements of commercial applications. Cummins’ focus on reliability, efficiency, and performance ensures that its components, including the 4944257 Sealing Washer, contribute to the success of commercial truck operations.

Compatibility of Cummins Sealing Washer 4944257

The Cummins Sealing Washer part number 4944257 is designed to ensure a secure and leak-free seal in various engine applications. This sealing washer is compatible with a range of Cummins engines, providing essential sealing functionality across multiple engine models.

B-Series Engines

The B5.9 CM2670 B166C, B6.7 CM2350 B135B, and B6.7 CM2670 B164C engines can utilize the 4944257 sealing washer. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The sealing washer ensures that connections remain tight and leak-free, maintaining the engine’s integrity.

D-Series Engines

The D4.0 CM2620 D103B engine is another model that can incorporate the 4944257 sealing washer. This engine is recognized for its efficiency and power, often used in various industrial and commercial applications. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s overall performance and longevity.

ISB Engines

The ISB (Chrysler) engine is compatible with the 4944257 sealing washer, ensuring that critical connections remain sealed and secure. This engine is known for its versatility and is used in a wide range of applications, from construction equipment to agricultural machinery. The sealing washer is essential for maintaining the engine’s efficiency and preventing leaks.

The ISB CM2150, ISB4.5 CM2350 B104, ISB6.7 CM2250, ISB6.7 CM2350 B101, ISB6.7 G CM2180 B118, and ISB6.7 CM2350 engines also utilize the 4944257 sealing washer. These engines are part of the ISB family and are designed for high-performance applications. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s reliability and efficiency.

ISV Engines

The ISV (Nissan) engine is another model that can incorporate the 4944257 sealing washer. This engine is known for its durability and is often used in heavy-duty applications. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s overall performance and longevity.

L-Series Engines

The L8.9 CM2670 L134C engine is part of the L-Series engines that can use the 4944257 sealing washer. This engine is designed for high-performance applications and requires reliable sealing to maintain its efficiency and durability. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s overall performance.

QSB Engines

The QSB6.7 CM2250, QSB6.7 CM2350 B105, and QSB6.7 M CM2250 engines are part of the QSB family and can utilize the 4944257 sealing washer. These engines are known for their power and efficiency, often used in various industrial and commercial applications. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s reliability and efficiency.

QSK Engines

The QSK95 CM2350 K111 and QSK95 CM2350 K113 engines are part of the QSK family and can incorporate the 4944257 sealing washer. These engines are designed for high-performance applications and require reliable sealing to maintain their efficiency and durability. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s overall performance.

QSL Engines

The QSL9 CM2350 L102 engine is part of the QSL family and can use the 4944257 sealing washer. This engine is known for its power and efficiency, often used in various industrial and commercial applications. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s reliability and efficiency.

Z-Series Engines

The Z14 CM2670 Z103B engine is part of the Z-Series engines that can utilize the 4944257 sealing washer. This engine is designed for high-performance applications and requires reliable sealing to maintain its efficiency and durability. The sealing washer ensures that all connections are properly sealed, contributing to the engine’s overall performance.

Role of Part 4944257 Sealing Washer in Engine Systems

The part 4944257 Sealing Washer is integral to maintaining the integrity and efficiency of various engine systems. It is employed in several key areas to ensure proper sealing and prevent leaks, which is essential for the optimal performance of the engine.

Connecting Rod and Piston

In the connecting rod and piston assembly, the Sealing Washer is used to secure the components together, ensuring that there are no gaps through which oil or gases can escape. This helps in maintaining the lubrication and cooling efficiency of the piston.

Cylinder Head

When installed in the cylinder head, the Sealing Washer plays a role in sealing the passages for coolant and oil. This is vital for maintaining the temperature regulation of the engine and preventing any cross-contamination between the coolant and oil systems.

Cylinder Head Leak Test Kit

During the use of a Cylinder Head Leak Test Kit, the Sealing Washer is often part of the setup to ensure that the test environment is sealed properly. This allows for accurate detection of any leaks in the cylinder head gasket or other sealing surfaces.

Exhaust Cooler Water Outlet Tube

In the Exhaust Cooler Water Outlet Tube, the Sealing Washer is used to ensure a tight seal at the connection points. This prevents water loss and maintains the efficiency of the exhaust cooling system, which is important for reducing emissions and protecting the engine from overheating.

Exhaust Gas Recirculation Cooler

Similarly, in the Exhaust Gas Recirculation Cooler, the Sealing Washer ensures that the recirculated exhaust gases are properly sealed within the system. This helps in reducing NOx emissions and improving the overall efficiency of the engine.

Exhaust Recirculation Water Plumbing

For the Exhaust Recirculation Water Plumbing, the Sealing Washer is crucial in maintaining the integrity of the water passages. This ensures that the water used for cooling the recirculated exhaust gases does not leak, thus maintaining the efficiency of the system.

Hardware Kit

In a Hardware Kit, the Sealing Washer is often included to be used in various applications throughout the engine. Its role is to provide a reliable seal in bolted connections, which is essential for the structural integrity and performance of the engine.

Lower Engine Gasket Kit

Within the Lower Engine Gasket Kit, the Sealing Washer is used to complement the gaskets by providing additional sealing at critical points. This is important for preventing oil leaks from the lower part of the engine, which could lead to performance issues and increased maintenance costs.

Male Union

At the Male Union connections, the Sealing Washer ensures a leak-proof seal. This is particularly important in systems where fluids under pressure are transferred, such as in the cooling or lubrication systems.

Marine Gear Oil Cooler Plumbing

In Marine Gear Oil Cooler Plumbing, the Sealing Washer is used to ensure that the oil cooling system remains sealed. This is essential for maintaining the viscosity and temperature of the gear oil, which directly affects the performance and longevity of the marine gear.

Mounting Kit

The Mounting Kit often includes Sealing Washers to ensure that the engine or its components are securely mounted without any leaks. This is important for the structural stability and vibration damping of the engine.

Performance Parts

In Performance Parts, the Sealing Washer is used to enhance the sealing capabilities of modified or high-performance engine components. This ensures that the modifications do not compromise the integrity of the engine’s sealing systems.

TUR Coolant Drain Tube

For the TUR Coolant Drain Tube, the Sealing Washer is used to ensure that the drain connections are sealed properly. This prevents coolant loss during maintenance procedures and ensures that the cooling system remains efficient.

TUR Coolant Supply Tube

In the TUR Coolant Supply Tube, the Sealing Washer ensures that the supply connections are sealed, maintaining the integrity of the coolant flow to the turbocharger. This is vital for the cooling and lubrication of the turbocharger, which directly affects its performance and lifespan.

Turbocharger Coolant Drain Tube

Similarly, in the Turbocharger Coolant Drain Tube, the Sealing Washer is used to prevent coolant leaks during maintenance, ensuring that the turbocharger’s cooling system remains efficient.

Turbocharger Coolant Plumbing

For the Turbocharger Coolant Plumbing, the Sealing Washer is essential in maintaining the integrity of the coolant passages. This ensures that the turbocharger receives adequate cooling, which is critical for its performance and durability.

Turbocharger Coolant Supply Tube

In the Turbocharger Coolant Supply Tube, the Sealing Washer ensures that the supply connections are sealed, maintaining the efficiency of the turbocharger’s cooling system.

Turbocharger Gasket Kit

Within the Turbocharger Gasket Kit, the Sealing Washer complements the gaskets by providing additional sealing at critical points. This is important for preventing leaks in the turbocharger system, which could lead to performance issues.

Turbocharger Kit

In a Turbocharger Kit, the Sealing Washer is used to ensure that all connections within the turbocharger system are sealed. This is essential for maintaining the efficiency and performance of the turbocharger.

Turbocharger Plumbing

For Turbocharger Plumbing, the Sealing Washer ensures that all fluid passages are sealed, preventing leaks that could affect the performance of the turbocharger.

Turbocharger Repair Kit

In a Turbocharger Repair Kit, the Sealing Washer is often included to replace worn or damaged washers. This ensures that the repaired turbocharger maintains its sealing integrity, which is essential for its performance and longevity.

Upper Engine Gasket Kit

Within the Upper Engine Gasket Kit, the Sealing Washer is used to complement the gaskets by providing additional sealing at critical points. This is important for preventing oil and coolant leaks from the upper part of the engine, which could lead to performance issues and increased maintenance costs.

Conclusion

The Cummins 4944257 Sealing Washer plays a vital role in ensuring the efficiency and reliability of various engine systems. Its compatibility with a wide range of Cummins engines and its use in critical components highlight its importance in maintaining the performance and longevity of commercial trucks. Regular maintenance and proper installation of this part are essential to ensure its effectiveness and contribute to the overall success of truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.