4934278

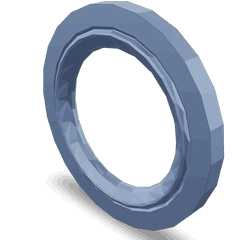

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Sealing Washer 4934278 by Cummins is engineered to fulfill a critical role within the mechanical systems of commercial trucks. Its primary function is to provide a secure seal in various applications, ensuring the integrity of fluid systems and preventing leaks. This component is vital for maintaining the operational efficiency and reliability of commercial trucks.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components designed to create a seal between two surfaces. They operate by filling the gap between mating surfaces, thereby preventing the leakage of fluids or gases. These washers are commonly used in various mechanical systems, including engines, hydraulic systems, and fuel systems, to ensure that fluids remain contained within their designated pathways 1.

Role of Sealing Washer 4934278 in Truck Operations

In commercial truck operations, the Sealing Washer 4934278 ensures the proper function of fluid systems. It is typically installed in areas where fluid lines connect or where components interface, such as in fuel injectors, oil filters, or coolant systems. By providing a reliable seal, this washer helps maintain system pressure, prevent fluid loss, and ensure that the truck’s systems operate efficiently 2.

Key Features

The Sealing Washer 4934278 is characterized by several key features that enhance its performance. It is constructed from materials that offer durability and resistance to the harsh conditions found in commercial truck environments. The design specifications of this washer ensure a precise fit and effective sealing capability. Additionally, any unique attributes, such as anti-extrusion properties or resistance to specific fluids, contribute to its overall effectiveness in truck applications 3.

Benefits

The incorporation of the Sealing Washer 4934278 into truck systems offers several benefits. It contributes to improved system efficiency by ensuring that fluids are properly contained and pressures are maintained. The durability and reliability of this washer also enhance the longevity of the truck’s mechanical systems, reducing the need for frequent replacements or repairs. Furthermore, its consistent performance supports the overall reliability of truck operations.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the Sealing Washer 4934278, regular maintenance and troubleshooting are recommended. Common issues may include wear and tear, deformation, or contamination, which can compromise the seal. Regular inspections and replacements, as necessary, can prevent these issues from affecting system performance. Additionally, ensuring that the washer is correctly installed and that mating surfaces are clean and undamaged can contribute to its effective operation.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s expertise in engine manufacturing and its dedication to advancing technology contribute to the reliability and performance of its products, including the Sealing Washer 4934278.

Cummins Engine Part 4934278: Sealing Washer Application

The Cummins part number 4934278, a sealing washer, is a critical component used in various Cummins engine models. This part is designed to provide a secure seal in applications where it is necessary to prevent leaks or maintain pressure integrity. Below is a detailed look at how this sealing washer fits into different Cummins engine configurations.

ISB Series Engines

The ISB series engines, known for their robust performance and reliability, utilize the sealing washer in several configurations:

- ISB CM2150

- ISB CM850

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B149

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISB6.7 CM2350 B101

These engines, which range from 4.5 to 6.7 liters, incorporate the sealing washer in various applications to ensure optimal sealing and performance.

ISBE and ISC Series Engines

The ISBE and ISC series engines, which are designed for heavy-duty applications, also use the sealing washer:

- ISBE4 CM850

- ISC CM2150

- ISC8.3 CM2250

These engines benefit from the sealing washer in maintaining the integrity of their sealing systems.

ISF and ISL Series Engines

The ISF and ISL series engines, which are known for their versatility and efficiency, include the sealing washer in their designs:

- ISF2.8 CM2220 F129

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

These engines, with displacements ranging from 2.8 to 9 liters, utilize the sealing washer to ensure reliable sealing in various applications.

ISM and ISX Series Engines

The ISM and ISX series engines, which are designed for high-performance applications, also incorporate the sealing washer:

- ISM CM876

- ISX CM871

These engines, with their high power outputs, rely on the sealing washer to maintain the integrity of their sealing systems.

Other Cummins Engines

Several other Cummins engines also use the sealing washer:

- 15N CM2380 M104B

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- C GAS PLUS CM556

- F3.8 CM2350 F129

These engines, with their diverse applications, utilize the sealing washer to ensure reliable sealing and performance.

The sealing washer, part number 4934278, is a versatile and essential component in Cummins engines, ensuring that these powerful machines operate efficiently and reliably across a wide range of applications.

Role of Part 4934278 Sealing Washer in Engine Systems

This Cummins part is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring that fluids, gases, and pressures are managed effectively within the engine environment.

Actuator Mounting Kit

In the actuator mounting kit, the sealing washer is positioned to prevent leaks between the actuator and its mounting surface. This ensures that the actuator operates within specified parameters without fluid intrusion, which could compromise performance.

Catalytic Converter

When integrated into the catalytic converter system, the sealing washer helps maintain the airtight seal necessary for optimal catalytic conversion. This prevents exhaust gases from escaping, ensuring that the converter functions efficiently in reducing emissions.

Corrosion Resistor Location

At corrosion resistor locations, the sealing washer plays a role in protecting sensitive components from moisture and corrosive elements. By creating a barrier, it extends the lifespan of these components and maintains system reliability.

EGR Cooler Kit

In the EGR (Exhaust Gas Recirculation) cooler kit, the sealing washer is essential for maintaining the seal between the cooler and its connections. This ensures that cooled exhaust gases are effectively recirculated without leaks, enhancing engine efficiency and reducing emissions.

Engine Coolant Vent

The sealing washer in the engine coolant vent system prevents coolant leaks, ensuring that the vent operates correctly to release excess pressure from the cooling system. This helps in maintaining optimal coolant levels and pressure, preventing engine overheating.

Engineering Valve Kit

Within the engineering valve kit, the sealing washer ensures that valves operate within a sealed environment. This is vital for maintaining the precision and reliability of valve functions, which are critical for engine performance.

Exhaust Cooler Water Outlet Tube

In the exhaust cooler water outlet tube, the sealing washer prevents water leaks, ensuring that the cooling process is efficient. This helps in maintaining the temperature of exhaust gases, which is essential for the overall engine cooling system.

Exhaust Recirculation Water Plumbing

The sealing washer in the exhaust recirculation water plumbing system ensures that water used in the recirculation process does not leak. This maintains the efficiency of the recirculation system, which is important for reducing NOx emissions.

Expansion Tank

In the expansion tank, the sealing washer prevents coolant leaks, ensuring that the tank can effectively manage the expansion and contraction of coolant as the engine heats up and cools down. This is vital for maintaining the integrity of the cooling system.

Gasket Kit

Within the gasket kit, the sealing washer complements other gaskets to ensure a comprehensive seal across various engine components. This is essential for preventing fluid and gas leaks, maintaining system pressure, and ensuring overall engine efficiency.

Incomplete Turbocharger and Incomplete Turbocharger Kit

In both the incomplete turbocharger and the incomplete turbocharger kit, the sealing washer ensures that all connections are sealed, preventing leaks that could affect turbocharger performance and efficiency.

Parts Distribution Center Kit

In the parts distribution center kit, the sealing washer ensures that all distributed parts are correctly sealed, preventing leaks and ensuring that the distribution system operates efficiently.

Plain Hose Coupling

The sealing washer in the plain hose coupling ensures a tight seal, preventing fluid leaks and maintaining the integrity of the hose connection. This is important for the reliable transfer of fluids within the engine system.

Radiator Plumbing

In the radiator plumbing system, the sealing washer prevents coolant leaks, ensuring that the radiator can effectively cool the engine. This is essential for maintaining engine temperature within safe operating limits.

Repair Service Kit and Service Kit

In both the repair service kit and the service kit, the sealing washer is a key component for ensuring that all repairs and services are performed with a reliable seal. This is important for maintaining the longevity and performance of the engine.

Turbocharger Actuator Kit

In the turbocharger actuator kit, the sealing washer ensures that the actuator operates within a sealed environment, preventing leaks that could affect turbocharger performance.

Turbocharger Cool Drain / Vent Tube

The sealing washer in the turbocharger cool drain/vent tube ensures that there are no leaks in the cooling and venting process, maintaining the efficiency of the turbocharger.

Turbocharger Gasket Kit

In the turbocharger gasket kit, the sealing washer complements other gaskets to ensure a comprehensive seal around the turbocharger, preventing leaks that could affect performance.

Turbocharger Housing Kit and Turbocharger Housing Repair Kit

In both the turbocharger housing kit and the turbocharger housing repair kit, the sealing washer ensures that the housing is sealed, preventing leaks that could compromise turbocharger efficiency.

Turbocharger Mounting Kit

In the turbocharger mounting kit, the sealing washer ensures that the turbocharger is mounted securely without leaks, maintaining the integrity of the mounting system.

Turbocharger Plumbing

In the turbocharger plumbing system, the sealing washer prevents leaks in the fluid and gas lines, ensuring that the turbocharger operates efficiently.

Upfit Kit

In the upfit kit, the sealing washer ensures that all additional components are securely fitted without leaks, maintaining the integrity of the upfit system and ensuring that it operates efficiently within the engine environment.

Conclusion

The Sealing Washer 4934278 by Cummins is a critical component in the maintenance and operation of commercial truck and engine systems. Its role in preventing leaks, maintaining system pressure, and ensuring the efficient operation of various engine components cannot be overstated. Regular maintenance and proper installation of this part are essential for the longevity and reliability of the systems it serves.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Berns, Karsten, et al. Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.