This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

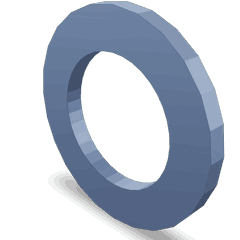

The Cummins 67526 Plain Washer is a component integral to commercial truck operations, designed to enhance the efficiency and reliability of truck performance. Understanding its purpose and role is essential for effective maintenance and repair of commercial trucks.

Basic Concepts of Plain Washers

Plain washers are fundamental components in mechanical systems, typically flat and annular, made from metal, plastic, or rubber. They distribute load, prevent surface damage, and provide spacing between parts, ensuring proper alignment and tightening of fasteners without undue stress on connected materials 1.

Purpose of the Cummins 67526 Plain Washer

This Cummins part ensures stable and even load distribution across connected components in commercial trucks. It is crucial in various truck components where fastening and alignment are critical, reducing the risk of surface and component damage 2.

Key Features

The Cummins 67526 Plain Washer is designed with specific material composition and specifications for durability and resistance to wear in demanding environments. Its precise dimensions and smooth surface facilitate easy installation and optimal function 3.

Benefits

Utilizing this part offers advantages such as durable construction for longevity, reliable performance for enhanced efficiency, and precise alignment and load distribution for improved performance and reduced wear on connected parts.

Installation and Usage

Proper installation of the Cummins 67526 Plain Washer is crucial for its function. It should be placed between the fastener and the surface it connects to for even load distribution. Best practices include checking for the correct size and material compatibility before installation. Common applications involve its use in engine components, transmission systems, and chassis assemblies where secure fastening is required.

Troubleshooting and Maintenance

To troubleshoot issues related to plain washers, inspect them for signs of wear or damage. Regular maintenance involves checking the condition of washers during routine inspections and replacing them if necessary to ensure optimal performance. Watching for signs of loosening or misalignment in connected components can also indicate the need for washer replacement.

Manufacturer Information - Cummins

Cummins is renowned in the automotive and heavy-duty truck industry for its commitment to quality and innovation. With a history of producing reliable components, Cummins ensures that products like the Cummins 67526 Plain Washer are designed to perform reliably in various truck applications.

Role of Part 67526 Plain Washer in Engine Systems

In engine systems, the 67526 Plain Washer ensures the smooth operation and longevity of various assemblies. Its application spans multiple components, each playing a distinct role in the overall functionality of the engine.

Assembly Fan Hub

Within the assembly fan hub, the Plain Washer maintains precise alignment and spacing between the fan blades and the hub, ensuring optimal airflow for effective engine cooling. It mitigates friction and wear, contributing to the durability of the fan hub assembly.

Belt Tension Arrangement

In the belt tension arrangement, the Plain Washer fine-tunes the tension of the belts that drive various engine accessories. By providing a consistent and even distribution of force, it helps maintain the efficiency and reliability of belt-driven systems, reducing the likelihood of belt slippage or breakage.

Belt Tensioning Arrangement

Similarly, in the belt tensioning arrangement, the Plain Washer plays a key role in adjusting and stabilizing the tension of the belts. This is essential for the proper functioning of components such as the alternator, water pump, and air conditioning compressor, ensuring they operate within their designed parameters.

Belt Tensioning Assembly

The belt tensioning assembly relies on the Plain Washer to facilitate smooth and consistent belt tension. This is particularly important in high-stress environments where the belts are subject to continuous motion and varying loads. The washer helps minimize wear and tear, thereby enhancing the lifespan of the belt tensioning assembly.

Belt Tensioning for Sea Water Pump

In marine applications, the belt tensioning for the sea water pump is critical for maintaining the cooling efficiency of the engine. The Plain Washer ensures that the belt tension is optimal, allowing the sea water pump to operate efficiently and reliably, even in harsh maritime conditions.

Fan Hub

The fan hub, responsible for dissipating heat from the engine, benefits from the Plain Washer by ensuring that the fan blades are securely and evenly spaced. This results in improved airflow and cooling performance, which is essential for the engine’s overall health and efficiency.

Pump

In various pump applications, whether for raw water, radiator cooling, or other fluids, the Plain Washer helps maintain the integrity of the pump’s moving parts. By reducing friction and wear, the washer ensures that the pump operates smoothly and efficiently, contributing to the consistent flow of fluids throughout the engine system.

Raw Water and Radiator Cooling

For raw water and radiator cooling systems, the Plain Washer is used in the pump and related assemblies to ensure that the cooling fluid is circulated effectively. This is vital for maintaining the engine’s operating temperature within safe limits, preventing overheating and potential damage.

Conclusion

The Cummins 67526 Plain Washer is a versatile and essential component in various engine systems, playing a significant role in ensuring the efficient and reliable operation of critical assemblies. Its proper installation and maintenance are crucial for the longevity and performance of commercial trucks.

-

Reif, Konrad Ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ -

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.