This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

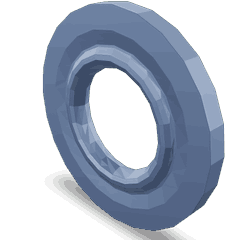

The Cummins 5441808 Sealing Washer is a critical component in heavy-duty truck maintenance and operation, designed to ensure the integrity of fluid systems by providing reliable seals at various joints and connections. This part is part of Cummins Inc.’s extensive range of automotive and heavy-duty truck parts, known for their quality and performance.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two or more parts, preventing leaks and maintaining the efficiency of fluid systems by filling gaps and ensuring that fluids do not escape from their intended pathways. In mechanical systems, sealing washers contribute to the overall integrity and performance of components by providing a barrier against fluid loss and contamination 1.

Purpose of the 5441808 Sealing Washer

The Cummins 5441808 Sealing Washer is specifically designed to seal joints and prevent leaks in the fluid systems of heavy-duty trucks. It is applied in areas where fluid transfer occurs, ensuring that the system remains closed and efficient. By preventing leaks, this washer helps maintain the pressure and flow of fluids, which is vital for the proper operation of the truck’s systems 2.

Key Features

The Cummins 5441808 Sealing Washer is characterized by its material composition, which is selected for durability and resistance to the harsh conditions found in heavy-duty truck environments. Its design specifications are tailored to fit precisely within the truck’s fluid systems, ensuring a tight seal. Unique attributes of this washer may include enhanced resistance to wear, corrosion, and environmental factors, contributing to its performance and longevity 3.

Benefits of Using the 5441808 Sealing Washer

Utilizing the Cummins 5441808 Sealing Washer offers several advantages. It provides improved sealing efficiency, reducing the risk of leaks and ensuring that fluid systems operate at optimal levels. Its longevity and resistance to wear and environmental factors mean that it requires less frequent replacement, contributing to lower maintenance costs and increased reliability of the truck’s fluid systems 4.

Installation Guidelines

Proper installation of the Cummins 5441808 Sealing Washer is key to ensuring its optimal performance and longevity. The installation process involves cleaning the mating surfaces, applying the appropriate lubricant if necessary, and positioning the washer correctly within the joint. Tools required may include wrenches for tightening connections and possibly a torque wrench to ensure the correct level of tightness is achieved without over-tightening, which could damage the washer or the components it seals.

Troubleshooting Common Issues

Common issues associated with sealing washers include leaks and wear. Diagnosing these problems involves inspecting the washer and the mating surfaces for signs of damage or misalignment. Resolving these issues may require replacing the washer, cleaning or repairing the mating surfaces, or adjusting the connection to ensure a proper seal is achieved.

Maintenance Tips

Regular maintenance of the Cummins 5441808 Sealing Washer involves periodic inspection for signs of wear or damage. Cleaning the washer and its mating surfaces can help prevent contamination that may lead to leaks. Replacement should be considered if the washer shows significant wear or if leaks persist despite other corrective measures. Adhering to recommended inspection intervals and maintenance procedures will help ensure the continued reliable operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its wide range of products, designed to meet the demanding requirements of various applications.

Cummins Sealing Washer 5441808 Compatibility

The Cummins Sealing Washer part number 5441808 is designed to fit seamlessly with various Cummins engines, ensuring optimal performance and longevity. This part is crucial for maintaining the integrity of engine seals and preventing leaks, which is essential for the smooth operation of the engines.

QSB6.7 M CM2250 Engines

The Sealing Washer 5441808 is compatible with the QSB6.7 M CM2250 engines. This compatibility ensures that the washer fits precisely within the engine’s design, providing a reliable seal that is essential for maintaining engine efficiency and preventing oil or coolant leaks.

Grouping of Compatible Engines

While the primary focus is on the QSB6.7 M CM2250 engines, it is important to note that the Sealing Washer 5441808 may also be compatible with other Cummins engines within the same family or series. This compatibility is due to the standardized design and specifications of the washer, which allows it to fit various engine models effectively.

Engines within the same series often share similar components and design features, making it easier to ensure that the sealing washer fits correctly and performs its intended function. This standardization is a testament to Cummins’ commitment to quality and consistency across their engine lineup.

Role of Part 5441808 Sealing Washer in Engine Systems

The part 5441808 Sealing Washer is a critical component in ensuring the efficient and reliable operation of various engine systems. Its primary function is to provide a secure and leak-proof seal between different components, thereby maintaining system integrity and performance.

In the instrument panel system, the Sealing Washer is utilized to ensure that all gauges and indicators receive accurate and consistent data from the engine. By preventing any fluid leaks or air intrusions, it helps maintain the precision of readings such as oil pressure, temperature, and other vital metrics. This ensures that the data displayed to the operator is reliable, allowing for informed decision-making during operation.

Within the engine instrument system, the Sealing Washer plays a significant role in maintaining the integrity of connections between sensors and the engine block. Sensors responsible for monitoring parameters like fuel levels, engine temperature, and emissions rely on secure connections to transmit accurate data. The Sealing Washer ensures that these connections remain intact, preventing any disruptions that could lead to incorrect readings or system failures.

In the broader panel system, which includes various control and display units, the Sealing Washer is used to secure connections and prevent environmental factors from affecting the system’s performance. This includes protecting against moisture, dust, and other contaminants that could compromise the functionality of the panel components.

Overall, the part 5441808 Sealing Washer is a fundamental element in maintaining the reliability and accuracy of engine systems by ensuring secure and leak-proof connections across various components.

Conclusion

The Cummins 5441808 Sealing Washer is a vital component in the maintenance and operation of heavy-duty trucks, ensuring the integrity of fluid systems and the reliable operation of engine systems. Its design, compatibility, and role in preventing leaks and maintaining system integrity underscore its importance in the automotive and heavy-duty truck industry.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.