This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

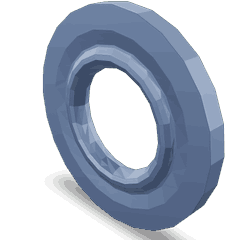

The Sealing Washer 4975528 is a component manufactured by Cummins, a prominent entity in the commercial truck industry. This washer is engineered to ensure the integrity and efficiency of various systems within commercial trucks.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components designed to prevent leaks in fluid systems by creating a tight seal between two surfaces. Their effectiveness is contingent upon their ability to withstand pressure, temperature variations, and the specific properties of the fluids they are designed to contain 1.

Purpose of the 4975528 Sealing Washer

The 4975528 Sealing Washer is utilized in commercial trucks to maintain seals in various fluid systems, including fuel, hydraulic, and cooling systems. By preventing leaks, it ensures the smooth operation of these systems, contributing to the overall efficiency and reliability of the truck 2.

Key Features

This Cummins part is characterized by its durable material composition, designed to withstand the harsh conditions of commercial truck applications. Its design includes specific dimensions and a smooth surface finish to ensure a tight seal. Additionally, it may feature resistance to certain chemicals or enhanced flexibility, contributing to its performance and longevity.

Benefits of Using the 4975528 Sealing Washer

Incorporating this part into a truck’s system enhances system efficiency by preventing leaks, which can lead to fluid loss and decreased performance. Its durability ensures longevity, reducing the need for frequent replacements. Furthermore, its reliable performance contributes to the overall dependability of the truck.

Installation and Usage Guidelines

Proper installation of the 4975528 Sealing Washer is crucial for its effective performance. Before installation, ensure that the mating surfaces are clean and free of any debris. Use the appropriate tools to install the washer, ensuring it is seated correctly without damage. Following manufacturer guidelines for torque specifications and alignment will help ensure optimal performance and longevity of the washer.

Troubleshooting Common Issues

Common issues with sealing washers include leaks and failures, which can arise from improper installation, wear and tear, or exposure to incompatible fluids. To troubleshoot these issues, first, verify the correct installation of the washer. Inspect for signs of wear or damage, and ensure compatibility with the system’s fluids. Addressing these factors can help resolve most problems associated with sealing washers.

Maintenance Tips

Regular maintenance of the 4975528 Sealing Washer is important to ensure its continued effectiveness. Inspect the washer during routine system checks for signs of wear or damage. Cleaning the washer and its mating surfaces can prevent contamination that may lead to leaks. Consider replacement if the washer shows significant wear or if system performance declines, to prevent potential failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for commercial vehicle operators worldwide.

Cummins Sealing Washer Part 4975528 Compatibility

The Cummins Sealing Washer part number 4975528 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is crucial in maintaining the integrity of the engine’s sealing system, preventing leaks and ensuring efficient operation.

QST30 CM2350 T101 and QST30 CM552

The Sealing Washer part 4975528 is compatible with the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of the Cummins QST30 series, known for their robust design and high performance. The washer fits precisely in these engines, providing a critical seal that is essential for maintaining pressure and preventing fluid leaks.

Application in Engine Systems

In the QST30 CM2350 T101 and QST30 CM552 engines, the sealing washer is typically used in areas where components interface, such as between the engine block and various auxiliary systems. Its role is to create a tight seal, ensuring that no contaminants or fluids escape, which is vital for the longevity and efficiency of the engine.

Importance of Proper Fitment

Ensuring that the sealing washer is correctly installed is crucial for the engine’s performance. An improperly fitted washer can lead to leaks, reduced efficiency, and potential engine damage. The part 4975528 is engineered to meet the specific requirements of these engines, providing a reliable and durable solution for sealing needs.

Installation Considerations

When installing the sealing washer part 4975528, it is important to follow the manufacturer’s guidelines. Proper installation involves ensuring that the washer is clean, free from debris, and correctly positioned to create an effective seal. This part should be replaced during routine maintenance or when signs of wear or damage are detected.

Role of Part 4975528 Sealing Washer in Engine Systems

The part 4975528 Sealing Washer is an essential component in various engine systems, ensuring the integrity and efficiency of fluid and air management.

Compressor and Air Systems

In compressor systems, the Sealing Washer is positioned to maintain airtight seals, preventing air leaks that could reduce compressor efficiency. It is integral in the air pathways, ensuring that the compressed air reaches its destination without loss of pressure.

Cover and Cam Follower Systems

When installed in covers and cam follower systems, the Sealing Washer helps in maintaining the structural integrity of these components. It prevents any fluid or air leakage that might occur around the cam follower, ensuring smooth operation and longevity of the cam mechanism.

Front Gear and Drive Systems

In front gear and drive systems, the Sealing Washer is used to seal the interfaces between rotating and stationary parts. This is vital for preventing lubricant loss and contamination, which can lead to increased wear and potential failure of the gear and drive components.

Auxiliary Pump and Fuel Pump Systems

For auxiliary pumps and fuel pumps, the Sealing Washer plays a role in sealing the pump housing. This ensures that the pumped fluid, whether it be fuel or lubricant, is delivered efficiently without any leakage, maintaining the system’s pressure and performance.

Filter and Lubricating Oil Systems

In filter systems and lubricating oil pathways, the Sealing Washer is critical for maintaining the seal around filter housings and oil passages. This prevents contamination of the lubricant and ensures that the filtration process is effective, prolonging the life of engine components.

Oil Transfer Connection and Package Systems

For oil transfer connections and packaged systems, the Sealing Washer ensures that oil is transferred efficiently between components without any spillage. This is important for maintaining the lubrication system’s integrity and ensuring that all moving parts receive adequate lubrication.

Product Installation and Plumbing Systems

During product installation and in plumbing systems, the Sealing Washer is used to create secure seals in various connections. This is essential for both fuel and general plumbing systems to prevent leaks and ensure that fluids are directed correctly throughout the engine.

Fuel and Fuel Drain Systems

In fuel systems and fuel drain pathways, the Sealing Washer is employed to prevent fuel leaks, which are not only a performance issue but also a safety concern. It ensures that fuel is contained within the system, delivering it efficiently to the combustion chambers.

Pulley and Accessory Drive Systems

For pulleys and accessory drive systems, the Sealing Washer is used to seal the interfaces where these components connect to the engine. This prevents lubricant loss and contamination, ensuring that the accessory drives operate smoothly and efficiently.

Pump and Accessory Drive Systems

Finally, in pump and accessory drive systems, the Sealing Washer is vital for maintaining seals in various connections and interfaces. This ensures that the pumps and drives function correctly, delivering fluids and power as needed throughout the engine system.

Conclusion

The 4975528 Sealing Washer by Cummins plays a significant role in maintaining the integrity and efficiency of various engine systems in commercial trucks. Its proper installation, maintenance, and compatibility with specific engine models are crucial for ensuring optimal performance and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.