This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

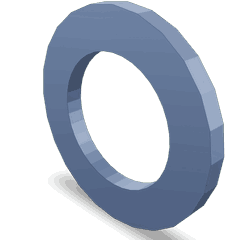

The Cummins 4951612 Plain Washer is a component utilized in heavy-duty truck assemblies. It serves a specific function within the mechanical systems of these vehicles, contributing to the overall efficiency and reliability of the truck. Understanding its purpose and significance is important for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Plain Washers

Plain washers are simple yet vital components in mechanical systems. They are typically flat, annular metal rings that are placed under nuts or bolts to distribute the load over a larger area, preventing damage to the surface 1. Additionally, plain washers can provide a degree of cushioning and help to reduce vibration and wear between moving parts.

Purpose of the Cummins 4951612 Plain Washer

The Cummins 4951612 Plain Washer plays a role in the fastening systems of heavy-duty trucks. It is designed to be used in conjunction with bolts and nuts to ensure that the load is evenly distributed across the surface it contacts. This helps to prevent damage to the components and ensures that the fastening system remains secure under various operating conditions.

Key Features

The Cummins 4951612 Plain Washer is characterized by its specific material composition, which is chosen for its durability and resistance to wear. The dimensions of the washer are tailored to fit precisely within the assemblies it is intended for, ensuring optimal performance. Additionally, any unique design elements, such as specific thickness or outer diameter, are intended to enhance its functionality within the truck’s mechanical systems.

Benefits of Using Plain Washers

Incorporating plain washers into truck assemblies offers several advantages. They help in distributing loads more evenly, which can prevent surface damage and extend the lifespan of components 2. Plain washers also contribute to reducing vibrations, which can lead to a smoother operation of the vehicle. Furthermore, depending on the material used, plain washers can offer corrosion resistance, which is particularly beneficial in harsh operating environments.

Installation and Usage Guidelines

Proper installation of the Cummins 4951612 Plain Washer involves placing it under the head of a bolt or nut. It is important to ensure that the washer is correctly aligned and seated to distribute the load effectively. Precautions should be taken to avoid over-tightening, which can lead to deformation of the washer or damage to the components. Following manufacturer guidelines for torque specifications is recommended to ensure optimal performance 3.

Troubleshooting and Maintenance

Common issues with plain washers may include deformation, corrosion, or wear. These problems can often be identified through regular inspections. Maintenance tips to prolong the lifespan of the washer include keeping it clean, replacing it if signs of wear are present, and ensuring that it is made from materials suitable for the operating conditions.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry. With a history of innovation and quality, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s reputation is built on its commitment to reliability, performance, and customer satisfaction.

Application in Cummins Engines

-

QSK60: The Plain Washer 4951612 is integral in the QSK60 engine, where it ensures that the components it interfaces with are properly aligned and sealed. This helps in maintaining the engine’s efficiency and reliability.

-

CM850: In the CM850 engine, the Plain Washer 4951612 plays a role in the assembly of various parts, ensuring that there are no gaps or misalignments that could lead to performance issues or failures.

-

MCRS: The MCRS engine also benefits from the use of the Plain Washer 4951612. This part is important in maintaining the structural integrity of the engine by providing a stable and secure connection between different components.

Importance of the Plain Washer

The Plain Washer 4951612 is a fundamental part in the Cummins engine ecosystem. Its primary function is to provide a flat surface that ensures proper sealing and alignment, which is crucial for the engine’s overall performance and durability. By preventing leaks and ensuring that components are correctly positioned, this washer helps maintain the engine’s efficiency and reliability.

Role of Part 4951612 Plain Washer in Engine Systems

In the context of the engine cooling system, the part 4951612 Plain Washer is instrumental in maintaining the integrity and efficiency of the system. It is positioned between various components to ensure a secure fit and proper sealing. This washer helps in preventing leaks by filling the gaps between the components, thus ensuring that the coolant flows smoothly without any interruptions. Its role is significant in maintaining the optimal temperature of the engine by facilitating efficient heat transfer.

When it comes to the heat exchanger, the part 4951612 Plain Washer plays a similar yet specialized role. In this application, the washer ensures that the connection points between the tubes and headers are sealed effectively. This is essential for the heat exchanger to function correctly, as it relies on the precise transfer of heat between the fluids. The washer helps in maintaining the structural integrity of the connections, preventing any potential leaks that could compromise the efficiency of the heat exchange process.

Conclusion

Overall, the Cummins 4951612 Plain Washer is a small yet vital component in these engine systems, contributing to their reliable operation and longevity. Proper understanding, installation, and maintenance of this part are crucial for the optimal performance and durability of heavy-duty trucks and engines.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.