This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

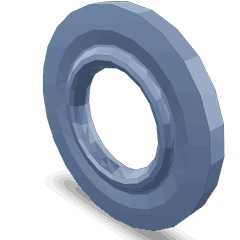

The Sealing Washer 4088596, manufactured by Cummins, is a critical component in the commercial truck industry. This part ensures the integrity and efficiency of various mechanical operations within commercial trucks.

Basic Concepts of Sealing Washers

Sealing washers are essential in mechanical systems to prevent leaks and maintain system integrity. They create a tight seal between surfaces, containing fluids or gases within the system. This is vital for the proper functioning of mechanical components, ensuring they operate under the correct pressure and without fluid or gas loss 1.

Purpose of Sealing Washer 4088596 in Truck Operation

This Cummins part plays a role in the operation of commercial trucks by ensuring the integrity of seals in various systems, such as the engine, transmission, or hydraulic systems. By providing a reliable seal, it helps maintain the efficiency and performance of these systems 2.

Key Features

The Sealing Washer 4088596 is characterized by its material composition and design attributes. Made from durable materials resistant to wear and corrosion, its design is tailored to fit specific applications, providing a secure seal that can withstand the pressures and temperatures encountered in commercial truck operations 3.

Benefits of Using Sealing Washer 4088596

Utilizing this part offers several advantages. It contributes to improved system efficiency by ensuring that fluids or gases are contained within the system, reducing the need for frequent maintenance. Additionally, its durable construction enhances the overall performance and reliability of the truck, leading to potentially lower operational costs over time.

Installation and Usage Guidelines

Proper installation of the Sealing Washer 4088596 is key to ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, which may include specific tools or procedures to ensure a secure fit. Attention to detail during installation helps prevent leaks and ensures the washer functions as intended within the system.

Troubleshooting Common Issues

Common issues with sealing washers, such as leaks or wear, can often be traced back to installation errors or environmental factors. Troubleshooting these issues may involve inspecting the washer for signs of damage, ensuring it is correctly installed, and addressing any external factors that may be contributing to the problem.

Maintenance Tips

Regular maintenance is important for prolonging the life of the Sealing Washer 4088596. This includes periodic inspections for signs of wear or damage and following replacement guidelines to ensure the washer continues to provide a reliable seal. Adhering to these practices helps maintain the efficiency and performance of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its wide range of products and commitment to quality. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and high-performance components, including the Sealing Washer 4088596. Their products are designed to meet the demanding requirements of commercial truck operations, ensuring durability and efficiency.

Role of Part 4088596 Sealing Washer in Engine Systems

In the context of engine systems, the 4088596 Sealing Washer is a critical component that ensures the integrity and efficiency of various fuel-related components.

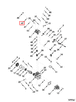

Fuel Injection Pump

Within the fuel injection pump, this part is positioned to prevent leaks between moving parts and stationary components. It ensures that pressurized fuel is delivered accurately and without loss, maintaining the pump’s performance and reliability.

Fuel Pump

In the fuel pump, the 4088596 Sealing Washer plays a similar role by sealing the connections between the pump body and the impeller or other rotating parts. This seal is vital for maintaining the pump’s efficiency, as any leakage could result in a drop in fuel pressure, affecting the overall performance of the engine.

Fuel Pump Assembly

When integrated into a fuel pump assembly, the 4088596 Sealing Washer ensures that all internal components work in unison without fuel escaping. This is particularly important in assemblies where multiple pumps or filters are housed together, as the washer helps maintain the structural integrity and functional efficiency of the entire unit.

Fuel Pump Head

At the fuel pump head, the 4088596 Sealing Washer is used to seal the connections between the pump head and the fuel lines or other attached components. This ensures that the fuel is delivered consistently to the engine, without any interruptions or losses, which is essential for the engine’s smooth operation.

Conclusion

Overall, the 4088596 Sealing Washer is a small yet significant component that contributes to the reliable operation of fuel systems in engines. Its role in preventing leaks and maintaining system integrity is crucial for the efficient and reliable performance of commercial trucks.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.