This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

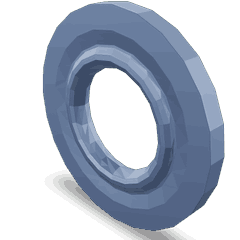

The Cummins 3864427 Sealing Washer is a critical component designed to maintain the integrity of fluid systems within heavy-duty trucks. It prevents leaks and maintains system pressure, contributing to the efficiency and reliability of truck operations. Understanding its function and significance is essential for maintaining the performance and longevity of heavy-duty vehicles.

Basic Concepts of Sealing Washers

Sealing washers are mechanical components used to create a seal between two surfaces, typically in fluid systems. They prevent fluid leakage and maintain system pressure. In heavy-duty trucks, sealing washers contribute to the efficient operation of various systems, including fuel, hydraulic, and cooling systems, by ensuring that fluids are contained within their designated pathways 1.

Purpose of the 3864427 Sealing Washer

The Cummins 3864427 Sealing Washer is designed to fit into various truck systems and components, where it seals connections and joints. Its application can be found in fuel injectors, hydraulic systems, and other critical areas where fluid containment is necessary. By providing a reliable seal, it helps maintain the operational integrity of these systems 2.

Key Features

The Cummins 3864427 Sealing Washer is characterized by its material composition, typically made from durable elastomers or synthetic materials that offer resistance to wear and chemical degradation. Its design attributes include a precise fit and flexibility, allowing it to conform to the surfaces it seals against. These features enhance its performance and durability, making it suitable for the demanding conditions of heavy-duty truck operations 3.

Benefits of Using the 3864427 Sealing Washer

Incorporating the Cummins 3864427 Sealing Washer into truck systems offers several advantages. It contributes to improved system efficiency by ensuring that fluids are contained and pressures are maintained. Additionally, its use can lead to reduced maintenance requirements, as its durable construction minimizes the need for frequent replacements. The reliability it offers enhances the overall performance and safety of truck operations.

Installation and Usage Guidelines

Proper installation of the Cummins 3864427 Sealing Washer is crucial for its effective performance. It should be installed in accordance with manufacturer guidelines, ensuring that it is correctly positioned and compressed to create a seal. Specific tools may be required to achieve the proper fit, and following the recommended procedures will help maintain the integrity of the sealing function.

Troubleshooting Common Issues

Common issues associated with sealing washers include leaks or failures, which can arise from wear, improper installation, or environmental factors. Diagnosing these issues involves inspecting the washer for signs of damage or wear and ensuring that it is correctly installed. Addressing these problems promptly can help maintain the efficiency and reliability of the truck’s fluid systems.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the Cummins 3864427 Sealing Washer. This includes periodic inspections for signs of wear or damage, cleaning the washer and its surrounding areas to prevent contamination, and following replacement guidelines based on usage and condition. Adhering to these practices will help ensure the continued performance and reliability of the sealing washer.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. Its commitment to quality and innovation is evident in its wide range of products, including the Cummins 3864427 Sealing Washer, designed to meet the rigorous demands of heavy-duty truck applications.

Cummins Sealing Washer 3864427 Compatibility with Engine Models

The Cummins Sealing Washer part number 3864427 is designed to fit seamlessly within several engine models, ensuring optimal performance and reliability. Here is a detailed overview of its compatibility with the specified engines:

6B5.9 Engine

The 6B5.9 engine benefits from the precision and durability of the 3864427 Sealing Washer. This part is engineered to provide a secure seal, preventing leaks and maintaining the engine’s operational integrity.

QSC8.3 CM850 (CM2850)

In the QSC8.3 CM850 (CM2850) engine, the 3864427 Sealing Washer plays a crucial role in maintaining the efficiency of the engine’s sealing system. Its compatibility with this engine ensures that the washer fits perfectly, providing a reliable seal that is essential for the engine’s performance.

QSC9 CM2250/QSL9 CM2250

The 3864427 Sealing Washer is also compatible with the QSC9 CM2250 and QSL9 CM2250 engines. These engines rely on the washer to maintain a tight seal, which is critical for preventing fluid leaks and ensuring the engine operates smoothly. The washer’s design ensures it fits these engines without any issues, providing the necessary sealing performance.

By ensuring the 3864427 Sealing Washer is used in these engines, operators can maintain the integrity of their engines, reduce the risk of leaks, and ensure long-lasting performance.

Role of Part 3864427 Sealing Washer in Engine Systems

In the context of engine systems, the part 3864427 Sealing Washer is instrumental in ensuring the integrity and efficiency of various components.

Drain Systems

Within drain systems, the Sealing Washer is positioned to prevent leaks at connection points. It is typically found at the junction where the drain line meets the engine block or oil pan. By creating a tight seal, it ensures that oil or other fluids are effectively channeled away from the engine without any seepage. This is particularly important in high-pressure environments where even minor leaks can lead to significant fluid loss and potential engine damage.

Remote Oil Systems

In remote oil systems, the Sealing Washer plays a similar yet specialized role. It is often used in the connections between the remote oil filter housing and the engine. This ensures that the oil flow remains uninterrupted and contamination-free. The washer helps maintain the pressure integrity of the system, which is essential for the efficient operation of the oil filter and the overall lubrication system.

In both applications, the Sealing Washer contributes to the reliability and performance of the engine system by ensuring that fluid pathways remain sealed and secure.

Conclusion

The Cummins 3864427 Sealing Washer is a vital component in maintaining the efficiency and reliability of heavy-duty truck fluid systems. Its precise design, durable material composition, and compatibility with various engine models make it an essential part for ensuring the operational integrity of these systems. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to maximizing the performance and longevity of this Cummins part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Frank Sander. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Alma Hillier. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.