3693654

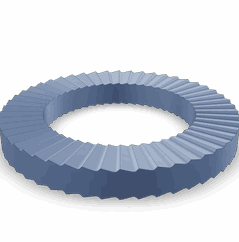

Lock Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3693654 Lock Washer is a specialized component designed for use in commercial trucks. Its primary function is to enhance the security of fasteners, ensuring they remain tightly in place under various operational conditions. This part is integral to maintaining the integrity and safety of truck components, particularly in environments where vibrations and stress are common 1.

Basic Concepts of Lock Washers

Lock washers are designed to prevent fastened components from loosening. Unlike regular washers, which primarily distribute load and prevent damage to the surface, lock washers incorporate features that create tension or bite into the fastened parts. This tension helps to counteract the effects of vibration and dynamic loads, which can cause standard fasteners to loosen over time 2.

Purpose of the Cummins 3693654 Lock Washer

The Cummins 3693654 Lock Washer secures fasteners under conditions of vibration and stress. It is designed to grip the surfaces it is placed between, thereby reducing the likelihood of fastener loosening. This is particularly important in commercial trucks, where components are subjected to significant stress and vibration during operation.

Key Features

The Cummins 3693654 Lock Washer is characterized by its unique design and material properties. It is typically made from high-strength steel, which provides durability and resistance to wear. The washer features a split design with bent ends that create a spring-like tension when installed. This design allows it to exert continuous pressure on the fastener and the surface it is attached to, enhancing the security of the fastening system.

Benefits of Using Lock Washers

Incorporating lock washers like the Cummins 3693654 into truck maintenance offers several advantages. These include improved fastening security, which reduces the risk of fastener loosening and potential component failure. Additionally, the use of lock washers can lead to reduced maintenance frequency, as fasteners are less likely to require re-tightening. This contributes to enhanced safety and reliability of the truck’s components 3.

Installation Guidelines

To ensure optimal performance and longevity of the Cummins 3693654 Lock Washer, it should be installed according to the following guidelines:

- Clean the fastening area to remove any dirt or debris.

- Place the lock washer under the bolt or nut, ensuring the bent ends are oriented correctly to create tension.

- Tighten the fastener to the manufacturer’s specified torque settings.

- Inspect the installation to ensure the lock washer is properly seated and functioning as intended.

Common Applications

The Cummins 3693654 Lock Washer is commonly used in various components and systems within commercial trucks. Typical applications include securing engine mounts, transmission components, and chassis parts. Its use is widespread in areas where vibration and dynamic loads are present, ensuring the longevity and reliability of these critical truck components.

Troubleshooting and Maintenance

Identifying and addressing common issues related to lock washers is important for maintaining truck performance. Signs of wear or failure may include visible deformation of the washer or loosening of the fastener. Regular inspection and replacement of worn lock washers are recommended to prevent component failure. Additionally, ensuring proper installation and torque settings can help extend the life of the lock washer and the fasteners it secures.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for commercial truck manufacturers and operators worldwide.

Role of Part 3693654 Lock Washer in Engine Systems

In the intricate assembly of engine systems, the Cummins 3693654 Lock Washer assumes a significant role by ensuring the stability and integrity of various components.

Integration with the Arrangement

Within the engine’s arrangement, the Lock Washer is employed to prevent fastening elements, such as bolts and nuts, from loosening due to engine vibrations. This is particularly important in high-stress areas where consistent tension is required to maintain the alignment and functionality of components. The Lock Washer achieves this by exerting a spring force that counters the loosening effects, thereby preserving the precise arrangement of parts.

Application in the Turbocharger

In the context of the turbocharger, the Lock Washer is utilized in the mounting process to secure the turbocharger to the engine. Turbochargers operate under extreme conditions, with high rotational speeds and temperatures, which can lead to significant vibrations. The Lock Washer helps to maintain the turbocharger’s secure attachment to the engine, ensuring that the connection remains tight and reliable. This is essential for the turbocharger’s efficiency and durability, as any loosening could result in performance issues or even failure.

Conclusion

By integrating the Cummins 3693654 Lock Washer into these critical areas, engineers and mechanics can enhance the reliability and performance of engine systems, ensuring that components remain securely fastened under the demanding conditions of engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.