This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

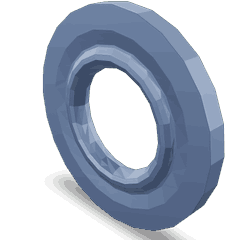

The Cummins 3336397 Sealing Washer is a component designed to ensure the proper functioning of commercial trucks. Its role is to maintain the integrity of fluid and pressure systems within the truck, contributing to the overall efficiency and reliability of the vehicle 1.

Basic Concepts of Sealing Washers

Sealing washers are components used in mechanical systems to prevent leaks and maintain pressure within fluid systems. They are typically placed between two surfaces to create a seal, ensuring that fluids do not escape and that systems operate under the correct pressure 2. In the context of trucks, sealing washers play a vital role in maintaining the performance and longevity of various systems, including the engine, transmission, and hydraulic systems.

Purpose of the 3336397 Sealing Washer

The Cummins 3336397 Sealing Washer is specifically designed to fit into various truck systems where fluid and pressure integrity is required. It is used in applications where a reliable seal is necessary to prevent leaks and maintain system pressure. This washer is integral to the operation of systems such as the engine, where it helps to seal connections and prevent oil leaks, and in the transmission system, where it ensures that hydraulic fluid is contained, contributing to smooth gear changes and overall transmission efficiency 3.

Key Features

The Cummins 3336397 Sealing Washer is characterized by its material composition, which is typically made from durable materials that can withstand high pressures and temperatures. Its design specifications include a precise fit to ensure effective sealing, and it may feature unique characteristics such as anti-rotation tabs or specific thickness to enhance its performance in demanding environments.

Benefits of Using the 3336397 Sealing Washer

Utilizing the Cummins 3336397 Sealing Washer offers several advantages. It contributes to improved system efficiency by ensuring that fluids are contained within the system, reducing the risk of leaks. Its durable construction promotes longevity, even under harsh operating conditions, and its reliable performance enhances the overall reliability of truck operations.

Installation Process

Proper installation of the Cummins 3336397 Sealing Washer involves several steps to ensure correct fitting. It is important to clean the mating surfaces to remove any debris that could compromise the seal. The washer should be placed in the designated location, and any accompanying hardware, such as bolts or clamps, should be tightened to the manufacturer’s specified torque settings to ensure a secure fit without over-tightening, which could damage the washer.

Common Issues and Troubleshooting

Common problems associated with sealing washers include leaks due to wear, improper installation, or damage. To address these issues, it is important to inspect the washer for signs of wear or damage and replace it if necessary. Ensuring that the washer is correctly installed and that all accompanying hardware is properly tightened can also help prevent leaks.

Maintenance Tips

To maintain the Cummins 3336397 Sealing Washer and ensure optimal performance, regular inspection routines should be established. This includes checking for signs of wear or damage and replacing the washer as needed. Following the manufacturer’s guidelines for replacement intervals can help prevent unexpected failures and maintain system integrity.

Role in Truck Systems

The Cummins 3336397 Sealing Washer integrates within various truck systems, including the engine, transmission, and hydraulic systems. Its role in these systems is to maintain fluid and pressure integrity, contributing to the overall performance and efficiency of the truck. By ensuring that fluids are contained and systems operate under the correct pressure, this washer plays a part in the smooth operation of the vehicle.

Cummins Corporation

Cummins Corporation is a well-established entity in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company has a history of innovation and commitment to providing solutions that enhance the performance and efficiency of commercial vehicles.

Compatibility with Engine Models

The Cummins Sealing Washer part number 3336397 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to provide a secure seal, preventing leaks and maintaining system integrity across different engine configurations.

Compatibility with QSV81G and QSV91G Engines

The Sealing Washer part 3336397 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust design and efficiency, and the sealing washer ensures that the components remain tightly sealed, preventing any fluid or gas leakage that could compromise engine performance.

Compatibility with QSW/QSV82, QSW27, and QSW36 Engines

The part 3336397 also fits the QSW/QSV82, QSW27, and QSW36 engines. These engines share similar design principles, focusing on durability and performance. The sealing washer is crucial in maintaining the integrity of the engine’s sealing system, ensuring that the engines operate at peak efficiency.

Compatibility with QSW73 and QSZ90 Engines

Lastly, the Sealing Washer part 3336397 is also compatible with the QSW73 and QSZ90 engines. These engines benefit from the washer’s ability to provide a tight seal, which is essential for maintaining the pressure and preventing leaks in high-stress environments. The compatibility ensures that the engines can operate reliably under various conditions.

By ensuring that the Sealing Washer part 3336397 is used with the appropriate engines, maintenance and operational efficiency can be significantly enhanced, contributing to the overall longevity and performance of the engines.

Role of Part 3336397 Sealing Washer in Engine Systems

The part 3336397 Sealing Washer is integral to maintaining the integrity and efficiency of various engine systems. In the Air Intake Assembly Manifold, it ensures that air enters the engine without leaks, optimizing combustion efficiency. Within the Air Starting Motor and Starting Sub-assembly Motor, the sealing washer prevents air or fluid leaks, ensuring reliable engine starts.

In the Assembly Housing Gear and Gear Assembly Housing, the washer maintains seal integrity, preventing lubricant loss and contamination. For the Camshaft, it ensures that the timing and lubrication systems remain leak-free, contributing to smooth engine operation.

The Charge Air Assembly Cooler benefits from the sealing washer by maintaining pressure and preventing coolant leaks, which is essential for efficient charge air cooling. In the Engine Cool Assembly Plumbing and Heat Exchanger, it plays a role in keeping the cooling system sealed, ensuring consistent engine temperatures.

The Expansion Assembly Tank uses the sealing washer to maintain pressure and prevent coolant loss, which is vital for the cooling system’s functionality. In the Flywheel Assembly Housing and Flywheel Housing, it ensures that the housing remains sealed, protecting internal components from contaminants.

For the Gear Equipped Housing and Gear Housing Gasket, the washer is essential in maintaining seal integrity, preventing lubricant leaks. In the Heat Assembly Exchanger and Lubricating Oil Filter, it ensures that these systems remain sealed, contributing to efficient operation and longevity.

The Motor Starting system and Power Take-off Assembly Housing rely on the sealing washer to prevent fluid leaks, ensuring reliable operation. In the Preheater Assembly Housing, it maintains seal integrity, which is important for effective preheating.

The Sea Water and Power Take-off Assembly Housing and Sea Water Pump Assembly Housing use the sealing washer to prevent seawater ingress and leaks, protecting internal components from corrosion. In the Turbocharger Arrangement, it ensures that the seals remain intact, contributing to efficient turbocharger operation.

Lastly, in the Water Connection, the sealing washer is vital for maintaining a leak-free connection, ensuring the integrity of the water system within the engine.

Conclusion

The Cummins 3336397 Sealing Washer plays a crucial role in maintaining the integrity and efficiency of various engine systems in commercial trucks. Its compatibility with a wide range of engine models ensures optimal performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall longevity and performance of the engines.

-

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Barton, David C., and John D. Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.