2870091

Sealing Washer

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Sealing Washers

Sealing washers are indispensable components in the assembly of commercial truck engines. Their primary function is to create a secure seal between two surfaces, preventing leaks and ensuring that fluids and gases remain within their intended systems. This article provides an in-depth look at the Cummins Part #2870091 Sealing Washer, highlighting its function, significance, and maintenance practices.

Basic Concepts of Sealing Washers

Sealing washers, also known as gasket washers, are thin, often metallic rings designed to fit into grooves or recesses on engine components. These washers are typically crafted from materials like stainless steel, copper, or specialized alloys, selected for their durability, resistance to corrosion, and ability to withstand high temperatures. The main purpose of a sealing washer is to prevent leaks by forming a tight seal between mating surfaces, which is crucial for maintaining engine efficiency and preventing contamination 1.

The Role of Cummins Part #2870091 Sealing Washer

The Cummins Part #2870091 Sealing Washer is specifically engineered for use in Cummins engines, which are renowned for their reliability and performance in heavy-duty applications. This sealing washer is designed to fit precisely into designated areas of the engine, ensuring that critical fluids such as oil, coolant, and fuel remain within their respective systems. By preventing leaks, the sealing washer helps maintain engine integrity and performance, thereby reducing the risk of engine damage and costly repairs 2.

Importance in Truck Operations

In the realm of commercial truck operations, the sealing washer plays a pivotal role in maintaining the efficiency and reliability of the engine. Leaks can lead to a host of issues, including reduced engine performance, increased fuel consumption, and potential engine failure. Ensuring that all seals are intact and functioning correctly is essential for the overall longevity and dependability of the truck. This is particularly important for fleet operators and truck drivers who rely on their vehicles for daily operations 3.

Troubleshooting and Maintenance

Proper maintenance of sealing washers is crucial to their effectiveness. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. If a sealing washer is found to be compromised, it should be replaced promptly to prevent leaks and potential engine issues. When replacing a sealing washer, it is important to use the correct part number and ensure that it is properly installed according to the manufacturer’s specifications.

Cummins: A Leader in Engine Manufacturing

Cummins is a renowned manufacturer of engines and related components, known for its commitment to quality and innovation. The company has a long history of producing reliable and efficient engines for a variety of applications, including commercial trucks. Cummins’ dedication to research and development ensures that their products meet the highest standards of performance and durability, making them a trusted choice for fleet operators and mechanics alike.

Cummins Sealing Washer Part 2870091 Compatibility

The Cummins Sealing Washer part number 2870091 is designed to fit a variety of Cummins engines, ensuring a proper seal and preventing leaks. This part is compatible with the following engines:

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

ISZ13 Series

- ISZ13 CM2150 Z105

QSX11.9 Series

- QSX11.9 CM2250 ECF

QSZ13 Series

- QSZ13 CM2150 Z102

This sealing washer is engineered to provide a reliable seal in various engine applications, ensuring optimal performance and longevity. It is crucial to verify the part number and specifications for your specific engine model to ensure compatibility and proper fitment.

Role of Part 2870091 Sealing Washer in Engine Systems

The part 2870091 Sealing Washer is integral to maintaining the integrity and efficiency of various engine components.

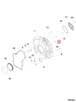

In the housing, the sealing washer ensures that there are no leaks between mating surfaces, which is essential for maintaining the pressure and fluid dynamics within the engine. This is particularly important in high-pressure environments where even minor leaks can lead to significant performance issues.

When integrated with the flywheel, the sealing washer helps to prevent oil or other lubricants from escaping, which is vital for the smooth operation of the flywheel. This ensures that the flywheel can engage and disengage with the engine components without any lubricant interference, thereby maintaining the efficiency of the power transmission.

In the context of the lower engine gasket kit, the sealing washer plays a role in ensuring that the gaskets perform their function effectively. By providing an additional layer of sealing, it helps to prevent coolant or oil leaks, which can otherwise lead to engine overheating or contamination.

Finally, within an overhaul kit, the sealing washer is often included to replace worn-out components during engine maintenance. Its role here is to restore the sealing integrity of the engine, ensuring that all fluids remain where they are supposed to be, thus prolonging the life of the engine and enhancing its performance.

Conclusion

The Cummins Part #2870091 Sealing Washer is an essential component in the operation of Cummins engines in commercial trucks. By understanding its function, importance, and maintenance requirements, engineers, mechanics, and fleet operators can ensure that their engines remain in optimal condition, reducing the risk of leaks and engine failure. Proper care and attention to sealing washers are key to maintaining the reliability and efficiency of commercial truck engines.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.