This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

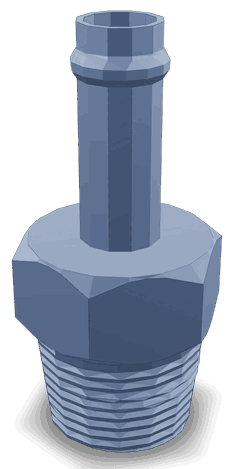

The Cummins 3354925 Vent Connection is a component designed to facilitate the venting process within the fuel system of commercial trucks. Its role is to ensure the proper release of air and vapors from the fuel tank, which is significant for maintaining the efficiency and safety of the truck’s operation 2.

Basic Concepts of Vent Connections

A vent connection is a component that allows for the controlled release of air and vapors from a system. In the context of a truck’s fuel system, it ensures that the fuel tank does not become over-pressurized, which could lead to leaks or other safety hazards. The operation of a vent connection is based on the principle of maintaining a balance between the internal pressure of the fuel tank and the external atmospheric pressure 1.

Purpose of the 3354925 Vent Connection

The 3354925 Vent Connection plays a specific role in the operation of a truck by facilitating the venting of air and vapors from the fuel system. This function is vital for several reasons: it helps to maintain the integrity of the fuel system by preventing over-pressurization, it contributes to the efficient operation of the fuel system by allowing for the smooth flow of fuel, and it enhances safety by reducing the risk of fuel leaks or explosions due to built-up pressure 2.

Key Features

The 3354925 Vent Connection is characterized by several key features that enhance its functionality. It is constructed from durable materials that can withstand the harsh conditions of a commercial truck’s operating environment. Its design includes elements that ensure a secure fit within the fuel system, and it may incorporate features that facilitate easy installation and maintenance 3.

Benefits

The use of the 3354925 Vent Connection offers several benefits. It contributes to improved fuel system efficiency by ensuring that the fuel tank operates within safe pressure limits. It enhances safety features by reducing the risk of fuel system failures due to pressure build-up. Additionally, it may offer potential cost savings for fleet operators by extending the lifespan of the fuel system components and reducing the need for repairs 2.

Installation Process

Installing the 3354925 Vent Connection requires following a step-by-step process to ensure proper fitting. The process may involve using specific tools or equipment to secure the connection within the fuel system. Best practices for installation include ensuring that all connections are tight and secure, and that the vent connection is properly aligned with the fuel tank and other system components 3.

Troubleshooting Common Issues

Common issues that may arise with the 3354925 Vent Connection include leaks, blockages, or malfunctions due to wear and tear. Troubleshooting these issues may involve inspecting the connection for signs of damage, cleaning or replacing the connection if necessary, and ensuring that it is properly installed within the fuel system 2.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 3354925 Vent Connection. This may include periodic inspections to check for signs of wear or damage, cleaning the connection to remove any buildup that could impede its function, and replacing the connection if it shows signs of significant wear or malfunction 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation within the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product offerings are designed to meet the demanding requirements of commercial applications, providing reliable and efficient power solutions for a variety of industries 2.

Vent Connection Part 3354925 Compatibility with Cummins Engines

The Vent Connection part 3354925, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s ventilation system, ensuring proper airflow and pressure management within the engine’s components. Here is a detailed look at the compatibility of this part with various Cummins engines:

4B3.9, 6B5.9, 6C8.3, B6.7 G CM0H6.0, B125

The Vent Connection part 3354925 is compatible with the following engines:

- 4B3.9

- 6B5.9

- 6C8.3

- B6.7 G CM0H6.0

- B125

These engines, while differing in size and power output, share a common design philosophy that allows the part to fit seamlessly, ensuring optimal ventilation and performance 2.

ISB6.7 G CM2180 B118, QSB6.7 M CM2250

The part is also compatible with the following engines:

- ISB6.7 G CM2180 B118

- QSB6.7 M CM2250

These engines are part of Cummins’ lineup of high-performance diesel engines, and the Vent Connection part 3354925 is engineered to meet the specific ventilation requirements of these models 2.

QSC9 CM2250/QSL9 CM2250, QSL9 CM2350 L102

Finally, the part fits the following engines:

- QSC9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

These engines are designed for heavy-duty applications, and the Vent Connection part 3354925 ensures that the ventilation system operates efficiently, even under demanding conditions 2.

Role of Part 3354925 Vent Connection in Engine Systems

The part 3354925 Vent Connection is integral to the efficient operation of several engine systems. It facilitates the proper venting and pressure regulation across various components, ensuring optimal performance and longevity.

Crankcase Breather Plumbing

In the crankcase breather system, the Vent Connection allows for the release of gases and vapors that accumulate within the crankcase. This prevents pressure build-up, which could lead to oil leaks and reduced engine efficiency. The Vent Connection ensures that these gases are directed away from the engine, maintaining a stable internal pressure 1.

Fuel System Primer

Within the fuel system, the Vent Connection plays a role in priming by allowing air to escape from the fuel lines during the priming process. This ensures that the fuel system is properly pressurized, facilitating a smooth start-up and consistent fuel delivery to the engine 2.

Refrigerant Compressor

For systems equipped with a refrigerant compressor, the Vent Connection helps manage the pressure within the refrigerant lines. It allows for the safe release of excess pressure, preventing damage to the compressor and ensuring efficient cooling performance 1.

Cabin Heater

In the cabin heating system, the Vent Connection assists in venting any excess pressure that may build up within the heater core and associated plumbing. This helps maintain the integrity of the heating system and ensures consistent warmth within the cabin 2.

Radiator and Engine Coolant

The Vent Connection is also vital in the radiator and engine coolant system. It allows for the release of air pockets that may form within the cooling system, ensuring that coolant circulates efficiently. This prevents overheating and maintains the engine at an optimal operating temperature 1.

Corrosion Resistor and Thermostat Housing

In conjunction with the corrosion resistor and thermostat housing, the Vent Connection helps in managing the pressure within these components. This ensures that the thermostat operates within its designed parameters, contributing to the engine’s thermal management 2.

Overall System Integration

The Vent Connection is a key component in the overall integration of these systems. It ensures that each system operates within its designed pressure parameters, contributing to the engine’s reliability and performance. Proper venting through this component prevents issues such as leaks, inefficiencies, and potential damage to engine components 3.

Conclusion

The Cummins 3354925 Vent Connection is a critical component in the maintenance and operation of commercial truck fuel systems. Its role in ensuring proper venting and pressure regulation across various engine systems contributes to the efficiency, safety, and longevity of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring optimal performance and reliability in demanding commercial applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.