This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3043438 Vent Tube is a critical component designed to facilitate the proper functioning of commercial trucks. Its role is to manage pressure and fluid levels within the truck’s system, ensuring optimal performance and longevity. Cummins Inc., the manufacturer, is renowned in the industry for its commitment to innovation and quality, providing reliable components that enhance the efficiency and safety of commercial vehicles 2.

Function and Operation

The Cummins 3043438 Vent Tube operates by allowing air to enter or exit a system, thereby equalizing pressure and managing fluid levels. This function is vital in preventing system overpressure and ensuring that fluids are properly contained and circulated. The basic principle behind vent tubes in automotive applications is to maintain a balanced environment within the system, which is essential for the efficient operation of various components 1.

Key Features

The design and construction of the Cummins 3043438 Vent Tube incorporate materials selected for their durability and resistance to the harsh conditions found in commercial truck environments. The tube is engineered to withstand high pressures and temperatures, ensuring reliable performance over time. Unique features may include reinforced connections and a design that minimizes the risk of leaks, enhancing both performance and durability.

Benefits

Using the Cummins 3043438 Vent Tube offers several advantages. It contributes to improved system efficiency by ensuring that pressure and fluid levels are maintained within optimal ranges. This can reduce the risk of component damage and enhance the overall safety of the truck’s operation. Additionally, the Vent Tube’s role in maintaining system integrity can lead to better truck performance and longevity.

Integration with Engine Components

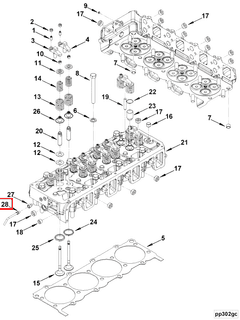

Camshaft and Cylinder Head

When integrated with the camshaft and cylinder head, the Vent Tube plays a significant role in ensuring that pressure does not build up excessively. The camshaft, a pivotal part responsible for the opening and closing of the engine’s valves, operates in a high-pressure environment. The Vent Tube helps in dissipating any excess pressure that could otherwise affect the camshaft’s performance.

Similarly, the cylinder head, which houses the combustion chambers, benefits from the Vent Tube by preventing pressure build-up that could lead to inefficiencies or even damage. By allowing gases to vent, the Vent Tube ensures that the cylinder head maintains a stable pressure, contributing to consistent engine performance.

Enhancing Performance Parts

In the realm of performance parts, the Vent Tube is often overlooked but is equally important. High-performance engines generate more pressure and heat, making the role of the Vent Tube even more significant. By effectively managing crankcase pressure, the Vent Tube allows performance parts to operate within their designed parameters, enhancing overall engine efficiency and reliability.

Contribution to Engine Performance

The Vent Tube’s ability to regulate pressure directly impacts engine performance. By ensuring that pressure levels remain within optimal ranges, the Vent Tube contributes to smoother engine operation, reduced wear on components, and improved fuel efficiency. This makes it a valuable component in both standard and high-performance engine systems.

Installation and Compatibility

Proper installation of the Vent Tube is key to its effective operation. Guidelines for installation should be followed to ensure a secure and effective fit. Compatibility with specific truck models and systems is important, and it is advisable to consult the manufacturer’s recommendations to ensure the Vent Tube is suitable for the intended application.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the Vent Tube continues to function correctly. This may include periodic inspections for signs of wear or damage, and cleaning or replacing the tube if necessary. Common issues that may arise include blockages or leaks, which can often be resolved through troubleshooting steps such as cleaning the tube or tightening connections.

Safety Considerations

When handling and installing the Vent Tube, it is important to follow safety protocols to prevent accidents or system failures. This includes adhering to manufacturer guidelines and using appropriate personal protective equipment. The Vent Tube plays a role in maintaining safe operating conditions by ensuring that pressure and fluid levels are managed effectively within the system.

Environmental Impact

The use of the Cummins 3043438 Vent Tube can have environmental considerations, particularly in terms of its contribution to reduced emissions and efficient fuel consumption. Proper maintenance and timely replacement of the Vent Tube can help ensure that the truck’s system operates efficiently, potentially leading to lower emissions and better fuel economy.

Cummins Overview

Cummins Inc. has a long history of providing reliable and high-quality components for the automotive industry. The company’s product range includes a variety of parts and systems designed to enhance the performance and efficiency of commercial trucks. Cummins’ commitment to innovation and quality has established it as a trusted name in the industry, recognized for its role in advancing automotive technology and providing solutions that meet the demanding needs of commercial vehicle operators 2.

Conclusion

In summary, the Cummins 3043438 Vent Tube is a vital component that works in conjunction with the camshaft, cylinder head, and various performance parts to maintain engine pressure, enhance performance, and ensure the longevity of engine components. Its role in managing pressure and fluid levels within the engine system is crucial for the efficient and safe operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.