This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

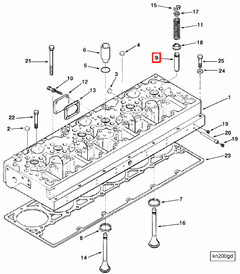

The Cummins 3033314 Valve Stem Guide is a component designed for use in heavy-duty truck engines. It plays a role in ensuring the proper operation of the engine’s valve system. This guide is integral to maintaining the alignment and functionality of the engine valves, contributing to the overall efficiency and reliability of the engine.

Basic Concepts of Valve Stem Guides

Valve stem guides are cylindrical components that support and guide the movement of engine valves. They ensure that the valves move up and down in a straight line, which is necessary for the valve’s interaction with other components such as the valve springs and valve seats. Proper alignment and smooth operation of the valves are necessary for efficient engine performance and longevity 1.

Purpose of the Cummins 3033314 Valve Stem Guide

This Cummins part maintains the alignment of the valves. It ensures that the valves operate correctly by providing a precise path for the valve stems to follow. This guide helps in reducing wear and tear on the valves and other related components, thereby contributing to the engine’s overall efficiency and durability 2.

Key Features

The Cummins 3033314 Valve Stem Guide is characterized by its material composition and design. It is typically made from high-quality materials that offer resistance to wear and corrosion. The design of the guide includes features that enhance its performance, such as a smooth inner surface to reduce friction and precise dimensions to ensure accurate valve alignment. These attributes contribute to the guide’s durability and effectiveness in demanding engine environments 3.

Benefits

Using the Cummins 3033314 Valve Stem Guide offers several advantages. It contributes to improved engine efficiency by ensuring that the valves operate smoothly and accurately. The guide’s durable construction enhances the engine’s reliability, allowing it to perform consistently under demanding conditions. Additionally, the precise alignment provided by the guide helps in maintaining the engine’s performance over time 4.

Installation and Maintenance

Proper installation of this part is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure that it fits securely and functions as intended. Regular maintenance, such as checking for wear and ensuring that the guide remains clean and free of debris, is important for maintaining optimal performance and longevity of the valve stem guide.

Troubleshooting

Common issues with valve stem guides may include wear, misalignment, or damage. These problems can lead to valve operation issues, such as leaks or misfires. Troubleshooting steps may involve inspecting the guide for signs of wear or damage, ensuring that it is properly aligned, and cleaning or replacing it as necessary to restore proper valve function.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. The company is known for its commitment to producing high-quality components that meet the demanding requirements of modern engines. Cummins’ expertise in engine technology and component manufacturing ensures that their products, including the 3033314 Valve Stem Guide, are designed to deliver reliable performance and durability.

Conclusion

The Cummins 3033314 Valve Stem Guide is a critical component in the operation of heavy-duty truck engines. Its role in maintaining valve alignment and reducing wear contributes significantly to engine efficiency and reliability. Proper installation, maintenance, and troubleshooting are essential to ensure the guide’s effective operation and the engine’s overall performance.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.