Introduction to Check Valves

A check valve is a critical component in fluid systems, allowing fluid (liquid or gas) to flow in one direction while preventing backflow. This functionality is essential in maintaining system efficiency and preventing damage. Check valves are integral to pipelines, pumps, and compressors, ensuring fluid moves in the desired direction 1.

How a Check Valve Works

The operation of a check valve is based on the principles of gravity and pressure differential. Typically, a check valve contains a disc or ball held in place by a spring. When fluid flows in the correct direction, the pressure pushes the disc or ball against the valve seat, allowing fluid passage. Conversely, when fluid attempts to flow in the opposite direction, the spring pushes the disc or ball back, sealing the valve and preventing backflow.

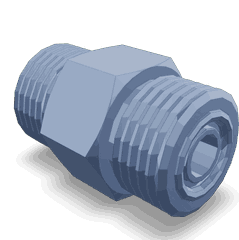

Purpose of Cummins Check Valve Part #5286583

The Cummins Check Valve Part #5286583 is engineered for commercial trucks and heavy-duty vehicles. Its main function is to ensure that fluids such as oil, coolant, and fuel move in the correct direction within the engine system. This prevents backflow, which can lead to inefficiencies, component damage, and potential engine failure.

Role in Truck Operations

In truck operations, the check valve plays a vital role in maintaining the engine’s lubrication system. It ensures consistent pressure and flow, preventing oil from flowing back into the sump when the engine is shut off. This helps maintain oil pressure and protects engine components. Additionally, it ensures that coolant flows correctly, preventing overheating and maintaining optimal engine temperature.

Troubleshooting Cummins Check Valve Part #5286583

A faulty check valve can result in several issues, including loss of oil pressure, overheating, poor fuel efficiency, and engine damage. To troubleshoot a faulty check valve, follow these steps:

- Inspect for Physical Damage: Examine the valve for any visible signs of wear, damage, or blockage.

- Test Fluid Flow: Use a pressure gauge to test the fluid flow in both directions. If there is backflow, the check valve is likely faulty.

- Check the Spring: Ensure the spring is not weakened or broken, as this can cause the valve to fail.

- Replace the Valve: If the check valve is found to be faulty, it should be replaced with a new one.

Maintenance Tips

Regular maintenance of the check valve can help prevent failures and extend its lifespan. Here are some maintenance tips:

- Regular Inspections: Periodically inspect the check valve for signs of wear or damage.

- Cleaning: Ensure the valve and its components are free from debris and contaminants.

- Lubrication: If applicable, ensure the valve’s moving parts are properly lubricated.

About Cummins

Cummins is a global leader in power solutions, pioneering the design and manufacture of engines, engine-related technology, and related parts. Known for their quality and reliability, Cummins products are trusted by fleet operators and mechanics worldwide. Their commitment to innovation and excellence ensures that their parts, including the Check Valve Part #5286583, meet the highest standards of performance and durability.

Role of Part 5286583 Check Valve in Engine Systems

In the context of engine systems, the Part 5286583 Check Valve is instrumental in maintaining the integrity and efficiency of fuel transfer processes. When integrated with the Fuel Transfer Pump, this check valve ensures that fuel flows in a single direction, preventing any backflow that could compromise the pump’s performance.

The Pump relies on consistent and unidirectional fuel flow to operate effectively. The check valve aids in this by allowing fuel to pass through during the pumping cycle while blocking any reverse flow when the pump is not actively transferring fuel. This unidirectional flow is essential for maintaining pressure and ensuring that the pump can deliver fuel efficiently to the engine components.

In scenarios involving Fuel Transfer between different parts of the engine system, such as from a secondary fuel tank to the primary system, the check valve plays a significant role. It ensures that fuel moves from the source to the destination without any unwanted reversal, which could lead to fuel starvation or contamination.

Overall, the Part 5286583 Check Valve is a key component in enhancing the reliability and performance of fuel transfer operations within engine systems.

Conclusion

This article provides a comprehensive understanding of the Cummins Check Valve Part #5286583, its function, importance, and maintenance. By adhering to the guidelines and tips provided, engineers, mechanics, truck drivers, and fleet operators can ensure the optimal performance and longevity of their commercial trucks and heavy-duty vehicles.

-

Daniel E. Williams, PhD, PE, Generalized Vehicle Dynamics, SAE Technical Documents.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.