This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

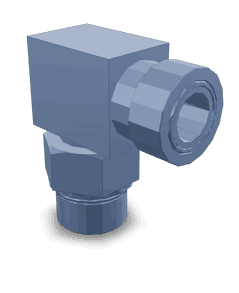

The Cummins 4349332 Check Valve is a component designed for use in commercial truck systems. It regulates the flow of fluids, ensuring they move in a single, intended direction within the system. This valve is integral to maintaining the efficiency and reliability of truck operations, particularly within the fuel or hydraulic systems.

Basic Concepts of Check Valves

Check valves, also known as non-return valves, allow fluid to flow through them in one direction only. They prevent reverse flow, which can be detrimental to system performance and component longevity. These valves operate using a simple mechanism where a disc or ball is lifted off its seat by the fluid pressure in the forward direction, allowing flow. When the pressure drops or reverses, the disc or ball returns to its seat, blocking the flow. Check valves find applications in various fluid systems, including water, gas, and hydraulic systems, to ensure proper fluid management and system integrity 1.

Purpose of the Cummins 4349332 Check Valve

The Cummins 4349332 Check Valve regulates fluid flow within the fuel or hydraulic systems of a truck. It ensures that fluid moves in the correct direction, preventing backflow that could lead to system inefficiency or damage. By maintaining consistent fluid direction, this valve contributes to the stable operation of the truck’s systems, enhancing overall performance and reliability.

Key Features

The Cummins 4349332 Check Valve is characterized by several key features that enhance its performance. Its design incorporates a durable construction with materials selected for their resistance to wear and corrosion. The valve’s compact size allows for easy integration into existing systems, while its precise engineering ensures reliable operation under varying conditions. Additionally, the valve may feature unique characteristics such as a silent check design to minimize noise during operation or a spring-assisted mechanism for quicker response times.

Benefits

The Cummins 4349332 Check Valve offers several advantages that contribute to system efficiency and reliability. By preventing backflow, it helps maintain consistent fluid pressure and flow rates, which are critical for the optimal operation of truck systems. The valve’s durable construction and reliable performance reduce the need for frequent maintenance, leading to lower operational costs. Furthermore, its integration into the system enhances overall reliability, ensuring that the truck operates smoothly under a wide range of conditions 2.

Installation Considerations

When installing the Cummins 4349332 Check Valve, it is important to follow guidelines and best practices to ensure proper function and system compatibility. The valve should be placed in a location where it can effectively regulate fluid flow without obstruction. It is also advisable to inspect the installation site for any potential issues that could affect valve performance, such as corrosion or debris. Ensuring that the valve is correctly oriented and securely fastened will contribute to its reliable operation and the overall efficiency of the system.

Troubleshooting Common Issues

Common problems associated with check valves include leakage, blockage, and failure to open or close properly. These issues can often be diagnosed through visual inspection or by monitoring system performance. Solutions may involve cleaning the valve, replacing worn components, or adjusting the valve’s position within the system. Regular maintenance and inspection can help prevent many of these issues, ensuring the valve continues to operate effectively.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4349332 Check Valve, routine maintenance practices should be followed. This includes regular inspection for signs of wear or damage, cleaning the valve to remove any buildup that could affect its operation, and testing its function periodically. Adhering to a maintenance schedule will help identify potential issues before they lead to system failure, ensuring the valve continues to contribute to the efficient operation of the truck.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry.

Role of Part 4349332 Check Valve in Engine Systems

The Cummins 4349332 Check Valve is an essential component in various engine systems, ensuring the unidirectional flow of fluids and gases. Its integration within these systems enhances efficiency and reliability.

Plumbing System

In the plumbing system, the Check Valve prevents backflow, ensuring that fluids move in the intended direction. This is particularly important in systems where fluid dynamics are complex, such as in multi-stage fuel delivery systems. By preventing reverse flow, the Check Valve maintains consistent pressure and flow rates, which are vital for the proper functioning of the plumbing network.

Fuel Pump Lubrication

When incorporated into the fuel pump lubrication system, the Check Valve ensures that lubricant reaches the pump components without any reverse flow. This consistent lubrication is essential for reducing friction and wear on moving parts, thereby enhancing the longevity and performance of the fuel pump. The Check Valve helps maintain a steady supply of lubricant, which is crucial for the pump’s efficient operation.

Primer System

In primer systems, the Check Valve plays a role in maintaining the pressure built up during the priming process. By preventing the primed fluid from flowing back, it ensures that the system remains pressurized and ready for immediate engine start-up. This is particularly beneficial in cold-start conditions where maintaining pressure is key to ensuring smooth engine operation.

Engine Lubricating System

Within the engine lubricating system, the Check Valve ensures that oil flows consistently to all critical engine components. It prevents oil from draining back into the sump when the engine is not running, ensuring that there is always a reserve of oil ready to lubricate the engine upon start-up. This consistent oil flow is essential for reducing friction, minimizing wear, and enhancing the overall efficiency of the engine.

Oil Reserve System

In systems with an oil reserve, the Check Valve ensures that the reserve oil is only released when needed, preventing any unnecessary drainage. This controlled release helps maintain the integrity of the oil reserve, ensuring that it is available when the engine requires additional lubrication. The Check Valve thus plays a key role in managing the oil supply, contributing to the engine’s reliable performance under varying operating conditions.

Conclusion

The Cummins 4349332 Check Valve is a vital component in commercial truck systems, ensuring the efficient and reliable operation of fuel and hydraulic systems. Its design and features contribute to the overall performance and longevity of truck engines, making it an essential part of Cummins’ engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.