This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3178912 Float Valve is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s fluid management system, contributing to the overall efficiency and reliability of the truck’s operation. Understanding its purpose and significance is key to maintaining the vehicle’s performance and longevity.

Basic Concepts of Float Valves

A float valve is a device used in fluid management systems to regulate the level of liquid within a tank. It operates using a float mechanism that rises and falls with the liquid level. When the liquid reaches a certain height, the float activates a valve that either allows more liquid to enter or stops the flow, maintaining a consistent level. Float valves are commonly used in various applications, including fuel and coolant systems, to ensure that the system operates within safe and efficient parameters 1.

Purpose of the Cummins 3178912 Float Valve

The Cummins 3178912 Float Valve plays a role in the fluid management system of commercial trucks by regulating the level of liquid, whether it be fuel or coolant. Its function is to maintain a consistent fluid level, which is vital for the proper operation of the truck’s engine and other systems. By ensuring that the fluid level does not drop too low or rise too high, the float valve helps to prevent engine damage and ensures optimal performance 2.

Key Features

The Cummins 3178912 Float Valve is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring a long service life. The valve’s design includes a precise float mechanism that accurately detects the fluid level and a robust valve assembly that can withstand the pressures and temperatures of the system it serves. Additionally, the valve may feature unique attributes such as a self-cleaning mechanism to prevent clogging and ensure consistent operation 3.

Benefits

The Cummins 3178912 Float Valve offers several benefits that contribute to the efficiency and reliability of commercial trucks. By maintaining a consistent fluid level, it helps to ensure that the engine and other systems operate within their designed parameters, which can lead to improved performance and fuel efficiency. The valve’s durable construction and precise operation also contribute to its reliability, reducing the likelihood of system failures and the associated downtime. Furthermore, by preventing fluid levels from becoming too low or too high, the valve can help to extend the life of the engine and other components, potentially offering cost savings over the long term.

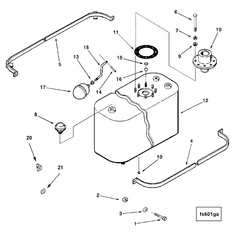

Installation Process

Installing the Cummins 3178912 Float Valve requires careful attention to detail to ensure proper function and integration within the truck’s fluid management system. The process typically involves several steps, including preparing the installation site, connecting the valve to the appropriate fluid lines, and securing it in place. It is important to follow the manufacturer’s instructions and use the recommended tools and fasteners to ensure a secure and leak-free installation. Prior to installation, it is also advisable to inspect the valve and associated components for any damage or defects that could affect performance.

Troubleshooting Common Issues

Float valves, including the Cummins 3178912, may encounter issues over time that can affect their performance. Common problems include clogging of the float mechanism, leaks in the valve assembly, and inaccurate fluid level detection. Troubleshooting these issues typically involves inspecting the valve for signs of wear or damage, cleaning or replacing the float mechanism as necessary, and checking the valve assembly for leaks or other defects. In some cases, it may be necessary to adjust the float level or replace the valve entirely to restore proper function.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3178912 Float Valve. This includes periodic inspection of the valve and associated components for signs of wear or damage, cleaning the float mechanism to prevent clogging, and checking the valve assembly for leaks or other issues. It is also important to follow the manufacturer’s recommended maintenance schedule and use only approved fluids and lubricants to ensure compatibility and performance. By adhering to these maintenance practices, truck operators can help to ensure that the float valve continues to operate efficiently and reliably over time.

Compatibility

The Cummins 3178912 Float Valve is compatible with a range of engine models, including the K19, K38, K50, and V28 engines. This part is engineered to meet the specific needs of these engines, ensuring that they run smoothly and efficiently.

Role in Engine Systems

The 3178912 Float Valve is an integral component in the regulation and management of fuel within various engine systems. Its primary function is to maintain a consistent fuel level within the float tank, ensuring optimal performance and efficiency of the engine. When integrated with accessories mounting systems, it ensures that all mounted accessories receive a stable fuel supply. Within the float tank, the valve operates to regulate the fuel level, preventing overflow and maintaining a consistent level. In systems that include a fuel transfer tank, the valve works in tandem to ensure that fuel is efficiently transferred between tanks. When utilized in fuel transfer tank conversion kits, the valve ensures seamless integration and operation of the new tank system. In general tank applications, whether it be the primary fuel tank or auxiliary tanks, the valve plays a significant role in maintaining consistent fuel levels, which is fundamental for the engine’s reliable operation and overall efficiency.

Conclusion

The Cummins 3178912 Float Valve is a critical component in the fluid management system of commercial trucks. Its role in maintaining consistent fluid levels contributes to the efficiency, reliability, and longevity of the truck’s engine and other systems. By understanding its purpose, features, and benefits, and by following proper installation, maintenance, and troubleshooting practices, truck operators can ensure that this Cummins part continues to operate efficiently and reliably over time.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.