This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

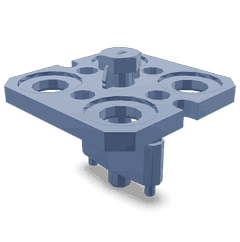

The Cummins 3164418 Valve Spring Compressor is a specialized tool designed for the maintenance and repair of heavy-duty truck engines. Its purpose is to facilitate the compression of valve springs, which is a necessary step during the replacement or inspection of valve train components. This Cummins part plays a role in ensuring that engine maintenance procedures are conducted efficiently and safely.

Basic Concepts of Valve Spring Compressors

A valve spring compressor is a tool used to compress the valve springs in an engine. This compression is necessary to remove and replace valve components such as the valve keeper and valve stem seals. The compressor works by applying force to the valve spring, reducing its tension and allowing for the removal of the valve train components. Valve spring compressors are important in engine maintenance as they enable technicians to perform necessary repairs and inspections without damaging the valve springs or other engine components 1.

Purpose of the Cummins 3164418 Valve Spring Compressor

The Cummins 3164418 Valve Spring Compressor is specifically designed to aid in the compression of valve springs during the replacement or inspection of valve train components in truck engines. By compressing the valve springs, it allows technicians to safely and effectively work on the valve components without the risk of the springs snapping back, which could cause injury or damage to the engine 2.

Key Features

The Cummins 3164418 Valve Spring Compressor is constructed with durability and ease of use in mind. It features a robust design that incorporates high-quality materials to ensure longevity and reliability. The ergonomic design of the compressor allows for comfortable handling and precise operation, reducing technician fatigue during prolonged use. Additionally, the compressor may include unique attributes such as adjustable settings to accommodate various valve spring sizes and types, enhancing its versatility and functionality 3.

Benefits of Using the Cummins 3164418 Valve Spring Compressor

Utilizing the Cummins 3164418 Valve Spring Compressor offers several advantages. It provides efficiency in use, allowing technicians to quickly and effectively compress valve springs. The reliability of the compressor ensures consistent performance, reducing the likelihood of tool failure during critical engine maintenance tasks. Furthermore, its design contributes to safer engine maintenance procedures by minimizing the risk of injury from spring tension and enhancing the overall effectiveness of valve train component work.

Troubleshooting and Maintenance Suggestions

Common issues with valve spring compressors may include difficulty in compressing springs or tool malfunction. To address these issues, it is important to ensure that the compressor is being used correctly and that it is compatible with the specific valve spring being worked on. Regular maintenance of the Cummins 3164418 Valve Spring Compressor, such as cleaning and inspecting for wear, can help ensure its longevity and optimal performance. Following the manufacturer’s guidelines for use and maintenance is also important.

Application in Engine Maintenance

The Cummins 3164418 Valve Spring Compressor is applied in practical engine maintenance scenarios by following a step-by-step process. First, the engine is prepared for work, ensuring it is cool and the valve cover is removed. The compressor is then positioned over the valve spring, and the compression mechanism is engaged to reduce the spring tension. Once the valve spring is sufficiently compressed, the valve train components can be safely removed or inspected. After the necessary work is completed, the compressor is released, allowing the spring to return to its normal position.

Safety Considerations

When using the Cummins 3164418 Valve Spring Compressor, it is important to observe safety practices and precautions. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential spring snap-back. Following the manufacturer’s guidelines and safety protocols is important to ensure a safe working environment. Additionally, ensuring that the compressor is used correctly and is in good working condition helps prevent accidents and injuries.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the automotive and engine manufacturing industry. The company is committed to innovation and quality, providing reliable and efficient engine components and tools that meet the demanding requirements of heavy-duty applications.

Conclusion

The Cummins 3164418 Valve Spring Compressor is an essential tool for the maintenance and repair of heavy-duty truck engines. Its robust design, ergonomic features, and reliable performance make it a valuable asset for technicians working on valve train components. By understanding the basic concepts, key features, and benefits of this Cummins part, technicians can ensure efficient and safe engine maintenance procedures.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Nunney, M. J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.