This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

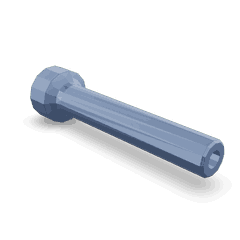

The 3163603 Valve Stem Seal Installer by Cummins is a specialized tool designed for the precise installation and removal of valve stem seals in heavy-duty truck engines. This Cummins part is significant in the maintenance and repair of these engines, ensuring that valve stem seals are correctly fitted, which is vital for maintaining engine efficiency and longevity 1.

Function and Operation

This part operates by providing a controlled and consistent method for installing and removing valve stem seals. When installing a seal, the tool ensures that it is seated correctly on the valve stem without damage, which is crucial for the seal’s effectiveness. The mechanical process involves aligning the tool with the valve stem, applying even pressure to seat the seal, and then carefully removing the tool without disturbing the seal. Precision is required to avoid over-compression or misalignment, which could lead to seal failure or engine performance issues 2.

Key Features

The Valve Stem Seal Installer is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. Key features include a precision-machined body that ensures accurate alignment with the valve stem, and a durable construction that withstands the rigors of repeated use in a workshop environment. Additionally, the tool may incorporate ergonomic handles for operator comfort and safety during use 3.

Benefits of Using the Valve Stem Seal Installer

Utilizing the Valve Stem Seal Installer offers several advantages. It enhances the efficiency of seal installation by providing a consistent and reliable method, reducing the time required for maintenance tasks. Proper seal fitting, facilitated by the installer, contributes to improved engine performance by ensuring optimal valve stem seal function, which is essential for maintaining compression and preventing oil leaks.

Troubleshooting and Maintenance

Common issues with the Valve Stem Seal Installer may include wear on the tool’s surfaces or misalignment due to improper use. Troubleshooting steps involve inspecting the tool for signs of wear, ensuring it is correctly aligned with the valve stem before use, and cleaning it after each application to remove any debris or contaminants. Regular maintenance, such as lubrication of moving parts and checking for structural integrity, ensures the longevity and optimal performance of the tool.

Role in Truck Engine Maintenance

Valve stem seals play a significant role in truck engines by maintaining compression and preventing oil from entering the combustion chamber. The Valve Stem Seal Installer contributes to the maintenance and repair process by facilitating the correct installation of these seals. Properly installed seals enhance engine efficiency and contribute to the overall longevity of the engine by ensuring that the valve train operates within specified parameters.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins provides high-quality tools and components for heavy-duty trucks. The company’s product range and dedication to advancing technology in the automotive and engine manufacturing industry underscore its role in supporting the efficiency and reliability of heavy-duty truck engines.

Conclusion

The 3163603 Valve Stem Seal Installer is an essential tool for the maintenance and repair of heavy-duty truck engines, offering precise installation and removal of valve stem seals. Its robust design, key features, and the benefits it provides in engine maintenance highlight its importance in ensuring engine efficiency and longevity. Regular maintenance and proper use of this Cummins part are crucial for its optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.