This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

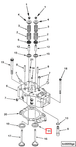

The Cummins 3094159 Valve Insert is a component designed for use in heavy-duty truck engines. It serves a specific function within the engine’s valve train, contributing to the overall performance and longevity of the engine. Understanding its role and significance can provide valuable insights into engine maintenance and operation.

Basic Concepts of Valve Inserts

A valve insert is a replaceable component that fits into the cylinder head of an engine. Its primary function is to provide a durable surface for the valve seat, which the valve contacts during operation. The valve insert interacts closely with the valve seat and valve stem, ensuring a proper seal and efficient operation of the valve mechanism. This interaction is crucial for maintaining engine efficiency and preventing issues such as valve leakage 1.

Purpose of the 3094159 Valve Insert

The 3094159 Valve Insert plays a role in the operation of a truck engine by providing a hard, wear-resistant surface for the valve seat. This contributes to the engine’s performance by ensuring a tight seal between the valve and the seat, which is necessary for efficient combustion and reduced emissions. Additionally, the insert enhances the durability of the cylinder head by allowing for the replacement of the valve seat surface without the need to replace the entire head 2.

Key Features

The 3094159 Valve Insert is characterized by its specific design and material properties. It is typically made from a hard, durable material that resists wear and high temperatures. The design of the insert allows for precise fitting into the cylinder head, ensuring a secure and reliable seal. These features contribute to the insert’s functionality and longevity within the engine 3.

Benefits

Using the 3094159 Valve Insert offers several advantages. It contributes to improved engine efficiency by ensuring a proper seal between the valve and seat, which is vital for optimal combustion. Additionally, the insert reduces wear on the cylinder head, leading to enhanced reliability and potentially extending the engine’s service life. The ability to replace the insert rather than the entire cylinder head also offers cost savings in maintenance and repair 4.

Installation Process

Installing the 3094159 Valve Insert requires careful attention to ensure a secure fit. The process involves preparing the cylinder head by cleaning the seat area and ensuring it is free of debris. The insert is then positioned into the seat and secured using appropriate tools to achieve the correct seating and alignment. Proper installation is key to ensuring the insert functions effectively within the engine.

Troubleshooting Common Issues

Common issues associated with valve inserts include leaks and wear. Leaks can occur if the insert is not properly seated or if there is damage to the insert or valve seat. Wear can result from improper installation, material defects, or excessive engine operation without maintenance. Diagnosing these issues involves inspecting the insert and valve seat for signs of damage or misalignment and addressing any identified problems through repair or replacement.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 3094159 Valve Insert. This includes periodic inspection of the insert and valve seat for signs of wear or damage, cleaning the area to remove any debris that could affect performance, and ensuring that the insert remains properly seated. Following manufacturer recommendations for inspection intervals and maintenance procedures is important for maintaining engine efficiency and reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is committed to advancing technology in the diesel engine and related technologies market. The company’s focus on quality, performance, and customer satisfaction has established it as a trusted name in the industry.

Valve Insert 3094159 Compatibility with Cummins Engines

The Valve Insert 3094159, manufactured by Cummins, is designed to fit seamlessly within specific engine models. This part is integral to the engine’s operation, ensuring optimal performance and longevity. Below is a detailed description of its compatibility with the listed engines:

QST30 CM2350 T101 and QST30 CM552

The Valve Insert 3094159 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. This compatibility ensures that the part can be used interchangeably across these models, providing a standardized solution for maintenance and repair needs.

-

QST30 CM2350 T101: This engine model benefits from the precision engineering of the Valve Insert 3094159, which is designed to fit perfectly within its valve assembly. This ensures efficient operation and reduces the risk of wear and tear.

-

QST30 CM552: Similarly, the QST30 CM552 engine is engineered to work optimally with the Valve Insert 3094159. The insert’s design aligns with the specific requirements of this engine model, ensuring that it meets the performance standards expected by Cummins.

By using the Valve Insert 3094159 in these engines, technicians and operators can be confident in the reliability and efficiency of their engine components. This compatibility is a testament to Cummins’ commitment to providing high-quality, interchangeable parts that enhance engine performance and durability.

Role of Part 3094159 Valve Insert in Engine Systems

The part 3094159 Valve Insert is an essential component in the orchestration of various engine systems, ensuring optimal performance and efficiency. Its primary function is to facilitate the precise control of airflow into and out of the cylinder, which is fundamental for combustion processes.

Interaction with the Cylinder Head and Cylinder

The Valve Insert is strategically positioned within the cylinder head, directly above the cylinder. It works in tandem with the valve mechanism to regulate the intake and exhaust of air and fuel mixture, as well as the expulsion of exhaust gases post-combustion. This regulation is vital for maintaining the correct air-fuel ratio, which is necessary for efficient combustion and power generation.

Coordination with the Camshaft and Gear

The operation of the Valve Insert is closely tied to the camshaft and gear system. As the camshaft rotates, driven by the engine’s timing gear, it actuates the valve mechanism through the use of cam lobes. This action opens and closes the Valve Insert at precise intervals, synchronized with the engine’s operation cycle—intake, compression, power, and exhaust.

Integration with the Fuel Manifold and Injector

In modern engine systems, the Valve Insert’s function is further enhanced by its interaction with the fuel manifold and injector. The fuel manifold distributes the fuel-air mixture to each cylinder, and the injector sprays a measured amount of fuel into the intake tract. The Valve Insert, by controlling the timing and duration of the intake valve’s opening, ensures that the fuel-air mixture is drawn into the cylinder at the optimal moment for combustion.

Contribution to Overall Engine Performance

The efficiency of the Valve Insert in its role directly impacts the engine’s overall performance. By ensuring that the valves open and close at the correct times and with the appropriate force, the Valve Insert contributes to the engine’s power output, fuel efficiency, and emissions levels. Its precise operation is a testament to the intricate balance required in engine design, where each component must work in harmony to achieve optimal performance.

Conclusion

The Cummins 3094159 Valve Insert is a critical component in the maintenance and operation of heavy-duty truck engines. Its design and functionality contribute to the engine’s efficiency, reliability, and longevity. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.