This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3093618 Check Valve is a component designed for use in commercial trucks. Its purpose is to regulate the flow of fluid within the truck’s system, ensuring that it moves in the intended direction. This valve contributes to the efficient operation of the truck by maintaining system integrity and preventing backflow, which can lead to inefficiencies and potential damage 2.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a mechanism that opens when the fluid flows in the correct direction and closes when the flow attempts to reverse. This functionality is vital in fluid systems to prevent backflow, which can cause contamination, system failure, or reduced efficiency. Check valves are commonly used in various applications, including water supply systems, fuel lines, and pneumatic systems 3.

Purpose of the 3093618 Check Valve

The Cummins 3093618 Check Valve serves a specific role within the operation of a truck. It is positioned in the system to allow fluid to pass through when the pressure is sufficient in the correct direction and to close off the flow when the pressure drops or reverses. This action helps maintain the desired pressure levels and flow direction within the truck’s system, contributing to the overall efficiency and reliability of the vehicle 2.

Key Features

The Cummins 3093618 Check Valve is characterized by several key features that enhance its performance. Its design incorporates a durable construction that can withstand the pressures and temperatures encountered in commercial truck applications. The valve is made from high-quality materials that offer resistance to corrosion and wear, ensuring longevity. Additionally, it may include unique attributes such as a spring-loaded mechanism for precise operation or a seal design that provides a tight shut-off to prevent leakage 2.

Benefits

The advantages provided by the Cummins 3093618 Check Valve include improvements in system efficiency and reliability. By preventing backflow, the valve helps maintain consistent pressure and flow within the system, which can lead to better performance and reduced maintenance requirements. Furthermore, the valve’s durable construction and reliable operation contribute to cost savings by minimizing the need for frequent replacements or repairs 2.

Installation Considerations

When installing the Cummins 3093618 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This may include verifying that the valve is oriented correctly to allow flow in the intended direction, ensuring that all connections are secure, and checking for any prerequisites such as specific pipe sizes or mounting requirements. Special tools may be required for installation, and it is advisable to consult the manufacturer’s instructions for detailed guidance 2.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3093618 Check Valve include leakage, failure to open or close properly, or damage due to wear or corrosion. Diagnostic tips for addressing these issues may involve checking for obstructions, inspecting the seal and spring mechanism, and verifying that the valve is installed correctly. Regular maintenance procedures, such as cleaning and inspecting for wear, can help ensure the valve’s longevity and optimal performance 2.

Performance in Various Conditions

The Cummins 3093618 Check Valve is designed to perform under a range of operating conditions. It can handle extreme temperatures and high-pressure environments, making it suitable for the demanding applications found in commercial trucks. The valve’s robust construction and precise operation allow it to maintain functionality and reliability even in challenging conditions 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s products are known for their reliability, efficiency, and durability, contributing to the success and performance of commercial vehicles worldwide 1.

Cummins Check Valve 3093618 Compatibility

The Cummins Check Valve part number 3093618 is designed to fit seamlessly within various engine models, ensuring optimal performance and reliability. This check valve is engineered to prevent backflow, which is crucial for maintaining system integrity and efficiency.

QST30 CM552 Engines

The Cummins Check Valve 3093618 is compatible with the QST30 CM552 engines. This compatibility ensures that the valve can effectively manage fluid flow within these engines, preventing any reverse flow that could compromise engine performance. The design of the valve is such that it integrates smoothly with the engine’s existing components, providing a reliable solution for maintaining system pressure and flow direction 1.

Grouping Compatibility

In addition to the QST30 CM552 engines, the Cummins Check Valve 3093618 is also suitable for use in other similar engine models. This grouping is based on the valve’s universal design, which allows it to fit a range of engines with similar fluid flow requirements. The valve’s robust construction and precise engineering ensure that it can handle the demands of various engine types, providing consistent performance across different applications 1.

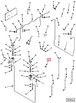

Role of Part 3093618 Check Valve in Plumbing and Fuel Systems

Plumbing Systems

In plumbing systems, the 3093618 Check Valve is instrumental in maintaining the unidirectional flow of water. It is typically installed in various sections of the plumbing network, including the supply lines and return lines. By preventing backflow, it ensures that water moves efficiently from the source to the point of use without any reverse flow, which could lead to contamination or reduced pressure. This valve works in conjunction with other components such as pumps, filters, and pressure regulators to maintain system integrity and performance 2.

Fuel Systems

Within fuel systems, the 3093618 Check Valve plays a significant role in ensuring the proper delivery of fuel to the engine. It is often positioned between the fuel tank and the fuel pump, as well as within the fuel lines leading to the engine. By preventing fuel from flowing backward, it helps maintain consistent fuel pressure and prevents fuel starvation. This is particularly important in high-performance engines where precise fuel delivery is essential for optimal combustion and engine efficiency. The Check Valve interacts with components such as the fuel pump, fuel filter, and injectors to ensure a seamless and reliable fuel supply 3.

Conclusion

The Cummins 3093618 Check Valve is a critical component in the efficient operation of commercial trucks. Its role in regulating fluid flow, preventing backflow, and maintaining system integrity contributes to the overall reliability and performance of the vehicle. With its durable construction, precise operation, and compatibility with various engine models, this part ensures consistent performance across different applications. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, leading to cost savings and reduced maintenance requirements.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.