3092511

Valve Spring Guide

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Valve Spring Guide 3092511, manufactured by Cummins, is a component designed to enhance the operation of heavy-duty truck engines. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this part to ensure efficient and reliable engine performance. The Valve Spring Guide 3092511 is integral to the valve train system, contributing to the overall functionality and durability of the engine 2.

Basic Concepts of Valve Spring Guides

A Valve Spring Guide is a mechanical component that supports and guides the valve spring within the engine. Its primary function is to maintain the proper alignment and operation of the valve spring, which in turn ensures the valve opens and closes correctly. The Valve Spring Guide interacts closely with other components such as the valve springs and valves, playing a role in the precise timing and efficiency of the engine’s valve operation 1.

Role of the Valve Spring Guide 3092511 in Truck Operation

The Valve Spring Guide 3092511 is specifically designed to enhance the stability and efficiency of the valve train in truck engines. By providing a stable platform for the valve spring, it helps maintain consistent valve operation under varying engine conditions. This contributes to improved engine performance, reduced wear on valve components, and enhanced overall engine reliability 2.

Key Features of the Valve Spring Guide 3092511

The Valve Spring Guide 3092511 boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design of the guide is optimized to provide a secure fit within the engine, minimizing the risk of misalignment. Additionally, it incorporates unique attributes that improve its functionality, such as precision machining and surface treatments that reduce friction and wear 3.

Benefits of Using the Valve Spring Guide 3092511

Utilizing the Valve Spring Guide 3092511 offers several advantages. It contributes to improved engine performance by ensuring precise valve operation. The guide’s durable construction and design characteristics increase the longevity of the valve train components. Furthermore, its reliable operation enhances the overall reliability of the engine, reducing the likelihood of unexpected failures and maintenance issues 2.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the Valve Spring Guide 3092511, it is important to be aware of common issues and perform regular maintenance. Common problems may include wear or damage to the guide, which can affect valve operation. Diagnostic procedures should involve inspecting the guide for signs of wear, ensuring it is properly seated, and checking for any damage. Maintenance practices include regular cleaning of the guide and its surrounding components to prevent buildup that could interfere with its function. Additionally, following the manufacturer’s recommendations for inspection and replacement intervals can help maintain engine performance 3.

Compatibility of Valve Spring Guide Part 3092511 with Cummins Engines

The Valve Spring Guide part 3092511, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engines. This part plays a crucial role in maintaining the proper function of the valve springs, ensuring that they operate smoothly and efficiently.

QST30 CM552 Engines

The Valve Spring Guide part 3092511 is specifically engineered to fit the QST30 CM552 engines. This compatibility ensures that the guide will align perfectly with the engine’s design, providing the necessary support and stability for the valve springs. The precision in manufacturing guarantees that the guide will function optimally, contributing to the overall performance and longevity of the engine.

Other Cummins Engines

While the primary focus here is on the QST30 CM552 engines, it is important to note that the Valve Spring Guide part 3092511 is also compatible with a broader range of Cummins engines. This compatibility extends to various engine models that share similar design specifications and operational requirements. Cummins’ commitment to quality and consistency in manufacturing ensures that this part will fit and perform well across multiple engine types, providing a reliable solution for engine maintenance and repair.

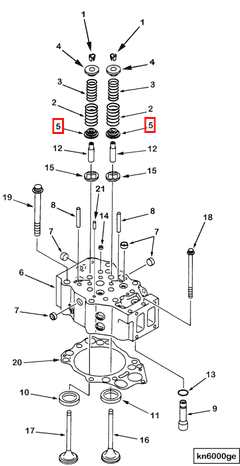

Role of Part 3092511 Valve Spring Guide in Engine Systems

The part 3092511 Valve Spring Guide is an integral component within the cylinder head assembly of an engine. It is specifically designed to maintain the alignment and stability of the valve spring, ensuring that the valve operates smoothly and efficiently.

In the cylinder head, the Valve Spring Guide works in conjunction with the valve spring, valve stem, and other related components to control the opening and closing of the intake and exhaust valves. This precise control is essential for optimal engine performance, as it directly affects the airflow into and out of the combustion chamber.

The Valve Spring Guide is positioned within the cylinder head, surrounding the valve stem. Its primary function is to prevent the valve spring from shifting or collapsing during engine operation, which could lead to valve float or other performance issues. By keeping the valve spring concentric with the valve stem, the guide ensures that the valve opens and closes at the correct times, maintaining the engine’s timing and efficiency.

Additionally, the Valve Spring Guide helps to reduce wear on the valve stem and spring, extending the lifespan of these components. It also contributes to the overall stability of the valve train, which is particularly important in high-performance engines where valve speeds and stresses are significantly higher.

Conclusion

In summary, the Valve Spring Guide 3092511 plays a significant role in the proper functioning of the cylinder head and the overall performance of the engine. Its design and placement are essential for maintaining the integrity and efficiency of the valve train system. Regular maintenance and proper installation are crucial to ensure the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.