This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

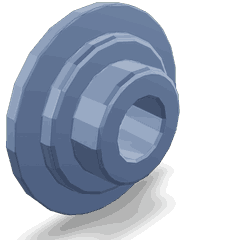

The Valve Spring Retainer, part number 3092510, manufactured by Cummins, is a critical component in the engine systems of heavy-duty trucks. Cummins, a renowned name in the heavy-duty truck industry, is known for its commitment to quality and innovation. This part is designed to enhance the efficiency and reliability of truck engines, playing a significant role in their overall performance.

Basic Concepts of Valve Spring Retainers

A Valve Spring Retainer is a component that secures the valve spring to the valve stem within an engine. Its function is to maintain the proper alignment and tension of the valve spring, ensuring that the valve operates correctly. The retainer interacts with other components such as valve springs and valves, contributing to the efficient opening and closing of the valves during engine operation 1.

Purpose of the 3092510 Valve Spring Retainer

The 3092510 Valve Spring Retainer is designed to contribute to the stability and efficiency of the valve train in a truck engine. By securely holding the valve spring in place, it ensures that the valve operates within the precise parameters required for optimal engine performance. This component plays a role in maintaining the integrity of the valve train, which is essential for the engine’s overall efficiency and reliability 2.

Key Features

The 3092510 Valve Spring Retainer is characterized by its robust design and material composition. Crafted from high-quality materials, it is engineered to withstand the demanding conditions typical of heavy-duty truck engines. Its design includes features that enhance its performance and durability, ensuring reliable operation under various operating conditions 3.

Benefits

The advantages provided by the 3092510 Valve Spring Retainer include improved engine performance, enhanced reliability, and increased longevity. By ensuring the proper function of the valve spring and valve, this component contributes to the overall efficiency and durability of the engine. Its high-quality construction and design features make it a valuable component for heavy-duty truck applications.

Installation and Compatibility

Proper installation of the 3092510 Valve Spring Retainer is crucial for ensuring optimal performance. It is important to follow manufacturer guidelines and recommendations to ensure that the component is installed correctly and functions as intended. Specific requirements or considerations may apply, depending on the engine model and application.

Troubleshooting and Maintenance

Identifying common issues related to Valve Spring Retainers and performing regular maintenance can help ensure continued reliable operation. Diagnostic procedures and maintenance practices should be followed to address any issues that may arise, contributing to the longevity and performance of the component.

Performance Under Stress

The 3092510 Valve Spring Retainer is designed to perform under various operating conditions, including high RPMs and heavy loads typical in heavy-duty truck applications. Its robust design and material composition enable it to withstand the stresses and demands of these environments, contributing to the reliable operation of the engine.

Material Durability and Longevity

The materials used in the 3092510 Valve Spring Retainer play a role in its durability and service life in demanding environments. High-quality materials are selected for their ability to withstand the stresses and conditions typical of heavy-duty truck engines, contributing to the component’s longevity and reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a reputable name in the heavy-duty truck industry. Its product range includes a variety of components and systems designed to enhance the performance and reliability of heavy-duty trucks.

Role of Part 3092510 Valve Spring Retainer in Engine Systems

The 3092510 Valve Spring Retainer is an essential component in the orchestration of an engine’s valve train system. Its primary function is to secure the valve spring in place, ensuring that the valve operates correctly under varying engine conditions.

Interaction with Camshaft and Gear

When the camshaft rotates, driven by the gear, it actuates the valve mechanism. The Valve Spring Retainer plays a pivotal role here by maintaining the integrity of the valve spring’s position. This ensures that the spring can effectively return the valve to its closed position after being opened by the camshaft lobe.

Coordination with Cylinder and Cylinder Head

In the cylinder and cylinder head assembly, the Valve Spring Retainer contributes to the precise control of the valve’s opening and closing cycles. This is vital for the combustion process, as it regulates the intake of air-fuel mixture and the expulsion of exhaust gases.

Integration with Fuel Manifold and Injector

The efficiency of the fuel manifold and injector is indirectly influenced by the Valve Spring Retainer. By ensuring the valve timing is accurate, the retainer helps in maintaining the optimal air-fuel ratio. This is essential for the injector to deliver fuel at the right moment, enhancing combustion efficiency and engine performance.

Contribution to Overall Engine Performance

In the broader context of engine performance, the Valve Spring Retainer, though a small part, is integral to the engine’s reliability and efficiency. It ensures that the valve train system operates smoothly, which is fundamental for the engine’s overall performance and longevity.

Conclusion

The 3092510 Valve Spring Retainer, manufactured by Cummins, is a vital component in the engine systems of heavy-duty trucks. Its robust design, material composition, and precise function contribute significantly to the engine’s efficiency, reliability, and longevity. Proper installation, maintenance, and understanding of its role in the engine system are crucial for optimal performance.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.