This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

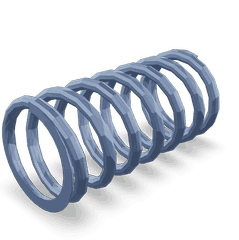

The Cummins 3092508 Valve Spring is a component designed for use in heavy-duty truck engines. Its purpose is to ensure the proper operation of the engine’s valve train by maintaining valve seat contact and controlling valve movement. The significance of this valve spring lies in its contribution to the overall performance and reliability of the engine, particularly under demanding conditions typical of heavy-duty applications.

Basic Concepts of Valve Springs

Valve springs are mechanical components found in internal combustion engines. Their primary function is to keep the valves in contact with their seats when the engine is not in the valve opening phase of the camshaft cycle. This ensures that the valves close completely, sealing the combustion chamber and preventing the escape of gases. Valve springs operate by compressing during the valve opening event and then expanding to return the valve to its closed position 1.

Role of the 3092508 Valve Spring in Truck Operation

The Cummins 3092508 Valve Spring plays a specific role in the engine’s valve train by ensuring that the valves open and close at the correct times and with the appropriate force. This is crucial for maintaining engine performance and efficiency, as it directly affects the timing and duration of the valve events, which in turn influence the engine’s power output, fuel efficiency, and emissions 2.

Key Features of the 3092508 Valve Spring

The Cummins 3092508 Valve Spring is characterized by its robust design and construction. It is made from high-quality materials that offer durability and resistance to the high temperatures and pressures found in heavy-duty truck engines. The spring rate is calibrated to provide the necessary force to keep the valves seated under all operating conditions, while also allowing for smooth and reliable valve operation. Unique characteristics may include a specific coil design that enhances performance and longevity.

Benefits of Using the 3092508 Valve Spring

Utilizing the Cummins 3092508 Valve Spring offers several advantages. These include improved engine reliability due to its durable construction, enhanced performance as a result of precise valve control, and increased longevity owing to its resistance to wear and fatigue. These benefits contribute to the overall efficiency and dependability of the engine.

Troubleshooting Common Issues with Valve Springs

Common issues with valve springs can manifest as valve train noise, decreased engine performance, or even engine misfires. Symptoms of valve spring failure may include visible damage to the spring, such as cracks or deformation, or signs of valve float, where the valve does not close completely. Diagnostic techniques involve visual inspection, listening for abnormal sounds, and performing compression tests to assess engine health 2.

Maintenance Tips for Valve Springs

To ensure optimal performance of valve springs, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, such as cracks or loss of tension. Replacement guidelines suggest that valve springs should be inspected during routine engine maintenance and replaced if any signs of failure are detected. Proper installation techniques are also important to maintain the integrity of the valve train 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines and parts designed to meet the demanding requirements of commercial and industrial applications.

Cummins Engine Compatibility with Valve Spring Part 3092508

The Cummins Valve Spring part number 3092508 is a critical component designed to fit seamlessly within specific Cummins engine models. This part is engineered to maintain the precise valve timing and performance required for optimal engine operation. Below is a detailed description of how this valve spring fits with the listed engines.

QST30 CM2350 T101 and QST30 CM552

The Cummins Valve Spring part 3092508 is compatible with both the QST30 CM2350 T101 and QST30 CM552 engines. This compatibility ensures that the valve spring functions effectively within these engines, maintaining the necessary pressure and tension to keep the valves securely closed during engine operation. The design of the valve spring is tailored to withstand the high temperatures and pressures typical of these engines, ensuring longevity and reliability.

The fitment of the valve spring in these engines is achieved through precise engineering, ensuring that the spring’s dimensions and material properties align perfectly with the engine’s specifications. This compatibility is crucial for maintaining the engine’s performance and efficiency, as any deviation in the valve spring’s fit could lead to operational issues such as valve float or failure.

By using the Cummins Valve Spring part 3092508 in these engines, users can expect consistent performance and reliability, as the part is specifically designed to meet the stringent requirements of Cummins engines. This ensures that the engines operate smoothly and efficiently, providing the power and durability that Cummins is known for.

Role of Part 3092508 Valve Spring in Engine Systems

The part 3092508 Valve Spring is an essential component in the orchestration of an engine’s operation, specifically within the cylinder head assembly. Its primary function is to ensure that the valves—both intake and exhaust—open and close at the precise moments dictated by the camshaft and gear mechanism.

When the camshaft rotates, driven by the engine’s timing belt or chain, it actuates the valve lifters or followers. These, in turn, push against the valves to open them, allowing air and fuel into the cylinder or expelling exhaust gases. The Valve Spring part 3092508 is responsible for returning the valve to its closed position once the camshaft’s influence wanes. This repetitive action must be performed with precision to maintain engine efficiency and performance.

The Valve Spring’s role becomes even more significant at higher engine speeds. As RPMs increase, the Valve Spring must withstand greater centrifugal forces and maintain its tension to prevent valve float, a condition where the valve does not seat properly and can lead to engine damage.

In the context of the cylinder (top-level assembly) head, the Valve Spring works in concert with other components to optimize engine performance. The fuel manifold delivers the air-fuel mixture to the intake ports, and the injectors spray fuel into the intake stream at the precise moment for combustion. The head, cylinder, and other parts must all function in harmony, with the Valve Spring ensuring that the valves operate correctly within this symphony of mechanical and electronic components.

The Valve Spring’s consistent performance is vital for the longevity and reliability of the engine. It must endure the extreme conditions within the engine compartment, including high temperatures and the constant cycle of compression and decompression as the engine operates.

Conclusion

In summary, the part 3092508 Valve Spring is a linchpin in the complex dance of engine components, ensuring that the valves perform their duty with the timing and precision required for optimal engine function. Its robust design, precise engineering, and compatibility with specific Cummins engines make it a critical component for maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.