This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

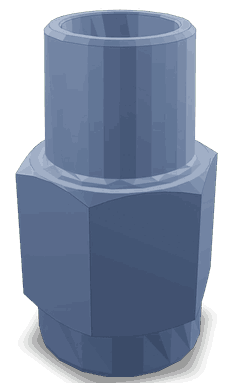

The Cummins 3084202 Check Valve is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, ensuring the proper direction of fluid flow and maintaining system integrity. Understanding its purpose and operation is key to maintaining the efficiency and reliability of commercial vehicles.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates by using a movable element, such as a flap or a ball, that opens to permit forward flow and closes to prevent reverse flow. Check valves are commonly used in fluid systems to prevent backflow, which can cause system damage or inefficiency. They are integral to the operation of various systems, including hydraulic, pneumatic, and fuel systems 1.

Purpose of the Cummins 3084202 Check Valve

The Cummins 3084202 Check Valve plays a role in the fluid systems of commercial trucks by ensuring that fluid flows in the intended direction. This is particularly important in systems where backflow could lead to contamination, reduced efficiency, or component damage. By maintaining the correct flow direction, the valve contributes to the overall performance and longevity of the truck’s systems 2.

Key Features

The Cummins 3084202 Check Valve is characterized by several design elements and materials that enhance its performance. It is constructed from durable materials to withstand the harsh conditions of commercial truck operations. The valve’s design includes a movable element that effectively seals the valve when fluid attempts to flow in the reverse direction. Additionally, it may feature anti-corrosion coatings or treatments to extend its service life in demanding environments 3.

Benefits

The advantages provided by the Cummins 3084202 Check Valve include improved system efficiency, increased reliability, and enhanced longevity. By preventing backflow, the valve helps maintain the integrity of the fluid system, reducing the risk of contamination and component wear. This results in more consistent performance and potentially lower maintenance costs over the life of the vehicle.

Installation Considerations

When installing the Cummins 3084202 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This may include verifying that the valve is oriented correctly to allow for forward flow and prevent backflow. Special tools or prerequisites may be required, depending on the specific application and the existing system configuration.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3084202 Check Valve include leakage, failure to seal properly, or obstructions that prevent the valve from operating as intended. Diagnostic steps for identifying problems may involve checking for proper orientation, inspecting for damage or wear, and ensuring that the valve is free from debris. Regular maintenance, such as cleaning and inspection, can help ensure optimal performance and longevity.

Performance in Various Conditions

The Cummins 3084202 Check Valve is designed to perform under a range of operating conditions, including varying temperatures, pressures, and fluid types. Its construction and materials are selected to withstand these conditions, ensuring reliable operation in the demanding environments typical of commercial truck applications.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality components that contribute to the efficiency, reliability, and performance of commercial vehicles.

Cummins Check Valve 3084202 Compatibility with Various Engines

The Cummins Check Valve 3084202 is designed to ensure unidirectional flow in hydraulic systems, preventing backflow and maintaining system efficiency. This check valve is compatible with several Cummins engine models, including the K19, QSK19 CM2350, K114, QSK19 CM500, and QSK19 CM850 MCRS.

K19 and QSK19 Series

The K19 and QSK19 series engines benefit from the 3084202 check valve due to its ability to maintain system pressure and prevent backflow. This is particularly important in applications where hydraulic systems are critical for engine operation, such as in steering and braking systems.

K114

The K114 engine also integrates the 3084202 check valve seamlessly. This engine model, known for its reliability and efficiency, relies on precise hydraulic control to function optimally. The check valve ensures that hydraulic fluid flows in the correct direction, enhancing the engine’s performance and longevity.

QSK19 CM2350, QSK19 CM500, and QSK19 CM850 MCRS

The QSK19 CM2350, QSK19 CM500, and QSK19 CM850 MCRS engines are part of Cummins’ high-performance lineup. These engines are used in demanding applications such as marine and heavy-duty trucking. The 3084202 check valve is crucial in these engines, as it helps maintain the high-pressure requirements necessary for optimal performance. Its design ensures that hydraulic systems operate smoothly, reducing the risk of wear and tear on critical components.

By integrating the 3084202 check valve, these engines achieve better efficiency, reliability, and longevity, making it an essential component for maintaining the integrity of the hydraulic systems.

Role of Part 3084202 Check Valve in Engine Systems

The 3084202 Check Valve is an essential component in various engine systems, ensuring the unidirectional flow of fluids and gases. Its integration within these systems enhances operational efficiency and reliability.

Accessories

In accessory systems, the 3084202 Check Valve prevents backflow, which is particularly important in hydraulic and pneumatic accessories. This ensures that the accessories receive a consistent supply of fluid or air, maintaining their performance and longevity.

Air Starting Systems

For air starting systems, the Check Valve plays a significant role by allowing air to flow in one direction only. This prevents any reverse flow that could compromise the starting sequence of the engine, ensuring a smooth and reliable start-up process.

Connection Bracket and Plumbing Systems

When installed in connection brackets and plumbing systems, the 3084202 Check Valve maintains the integrity of the fluid pathways. It ensures that fluids, whether they are engine oil, coolant, or other lubricants, flow in the intended direction, reducing the risk of contamination and system failure.

Engine Oil Primer Systems

In engine oil primer systems, the Check Valve is vital for priming the engine with oil before start-up. It allows oil to flow into the engine while preventing any backflow, ensuring that the engine components are adequately lubricated from the moment of ignition.

Prelube and Remote Systems

For prelube and remote systems, the Check Valve ensures that the prelube fluid reaches all necessary components without any reverse flow. This is essential for protecting engine bearings and other critical parts during the initial start-up phase.

Prelube Starter and Pre-lube Starter Kit

In prelube starter and pre-lube starter kit configurations, the Check Valve facilitates the proper distribution of lubricant to the engine components. This enhances the starter’s effectiveness and ensures that the engine is well-lubricated before operation, reducing wear and tear.

Pre-lube Starter Plumbing

Within pre-lube starter plumbing, the Check Valve maintains the directional flow of lubricants, preventing any potential backflow that could lead to inefficient lubrication and increased maintenance requirements.

Conclusion

The Cummins 3084202 Check Valve is a critical component in the fluid systems of commercial trucks, ensuring unidirectional fluid flow and maintaining system integrity. Its robust design, compatibility with various Cummins engines, and role in enhancing engine efficiency and reliability make it an indispensable part of commercial vehicle maintenance and operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.