This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

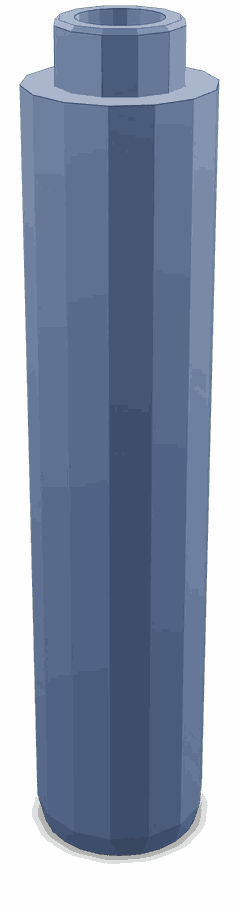

The Cummins 3081875 Valve Stem Guide is a component designed to facilitate the smooth operation of heavy-duty truck engines. Its purpose is to provide a precise pathway for the valve stem, ensuring efficient valve operation and contributing to the overall performance and reliability of the engine.

Basic Concepts of Valve Stem Guides

Valve stem guides are cylindrical components that support and guide the valve stems within the engine cylinder head. They play a role in maintaining the alignment and stability of the valve stems as they move up and down. These guides interact closely with other components such as valves and valve springs, ensuring that the valves open and close correctly in synchronization with the engine’s operation 1.

Purpose of the Cummins 3081875 Valve Stem Guide

The Cummins 3081875 Valve Stem Guide contributes to the operation of a truck engine by providing a stable and precise path for the valve stem. This ensures that the valve operates efficiently, which in turn supports the engine’s valve train system. By maintaining proper valve alignment and reducing friction, this component helps enhance engine performance and efficiency 2.

Key Features

The Cummins 3081875 Valve Stem Guide is characterized by its specific design and material properties. It is crafted from high-quality materials that offer durability and resistance to wear. The design ensures a snug fit within the cylinder head, which helps in minimizing lateral movement of the valve stem and reducing the potential for wear and tear on both the guide and the valve stem 3.

Benefits

The Cummins 3081875 Valve Stem Guide offers several advantages. It contributes to improved engine reliability by ensuring consistent valve operation. Additionally, it helps reduce wear on valve components, which can lead to extended engine life. The guide also plays a role in enhancing overall engine efficiency by supporting smooth and precise valve movement 4.

Installation and Compatibility

Proper installation of the Cummins 3081875 Valve Stem Guide is important for ensuring optimal performance. This involves careful placement within the cylinder head and ensuring that it is securely in position. It is also important to verify compatibility with the specific engine model to ensure that the guide fits correctly and functions as intended 5.

Maintenance and Troubleshooting

Regular maintenance practices can help ensure the longevity of the Cummins 3081875 Valve Stem Guide. This includes periodic inspection for signs of wear or damage and ensuring that it remains clean and free from debris. Common troubleshooting tips involve checking for proper valve operation and addressing any issues related to valve alignment or movement 6.

Performance Impact

The Cummins 3081875 Valve Stem Guide influences engine performance in several ways. By ensuring smooth and precise valve operation, it contributes to factors such as fuel efficiency, power output, and emissions. A well-functioning valve stem guide can help the engine operate more efficiently, which may lead to better overall performance 7.

Cummins Corporation Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the industry for producing high-quality automotive components. The company has a history of innovation and commitment to excellence, which is reflected in the design and performance of components like the Cummins 3081875 Valve Stem Guide 8.

Conclusion

The Cummins 3081875 Valve Stem Guide is a vital component in the operation of heavy-duty truck engines. Its role in ensuring efficient valve operation, reducing friction, and enhancing engine performance makes it an essential part of the engine’s valve train system. Proper installation, maintenance, and understanding of its function are key to maximizing the benefits this part offers.

-

TK Garrett, K Newton, W Steeds, The Motor Vehicle, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection, Delmar Cengage Learning, 2010.

↩ -

Michael Trzesniowski, The Complete Vehicle, Springer Nature, 2023.

↩ -

Cummins Inc., QSB4.5 CM2150 B108 Service Manual (4326163).

↩ -

Cummins Inc., QSB4.5 CM2150 B108 Service Manual (4326163).

↩ -

John Dixon, Modern Diesel Technology Preventive Maintenance and Inspection, Delmar Cengage Learning, 2010.

↩ -

Cummins Inc., QSB4.5 CM2150 B108 Service Manual (4326163).

↩ -

Cummins Inc., Company Overview, accessed on [date].

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.