This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3062158 Check Valve is a component designed for use in commercial truck systems. Its purpose is to ensure the unidirectional flow of fluid within the system, preventing backflow which could lead to inefficiencies or damage. This valve is integral to maintaining the proper operation of the truck’s systems, contributing to overall performance and reliability.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that allows fluid to flow through it in only one direction. It operates using a mechanism that opens when fluid flows in the correct direction and closes when the flow attempts to reverse. Check valves are commonly used in fluid systems to prevent backflow, which can cause contamination, system damage, or reduced efficiency. They find applications in various systems, including water, gas, and hydraulic systems 1.

Purpose of the Cummins 3062158 Check Valve

The Cummins 3062158 Check Valve plays a specific role in the operation of a truck by ensuring the unidirectional flow of fluid within the fuel or hydraulic systems. By preventing backflow, it helps maintain system pressure and efficiency, ensuring that the truck operates smoothly and reliably. This valve is particularly important in systems where backflow could lead to contamination or damage to sensitive components 2.

Key Features

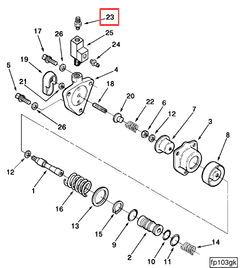

The Cummins 3062158 Check Valve is constructed from durable materials, ensuring longevity and reliability in demanding commercial truck environments. Its design includes a spring-loaded mechanism that opens and closes to allow or prevent fluid flow, respectively. Unique attributes of this valve may include a corrosion-resistant coating, which enhances its performance in harsh conditions, and a compact design that allows for easy integration into existing systems 3.

Benefits

The Cummins 3062158 Check Valve offers several advantages, including improved system efficiency and reliability. By preventing backflow, it helps maintain consistent system pressure and flow, which can enhance the performance of the truck’s fuel or hydraulic systems. Additionally, its durable construction and reliable operation contribute to the overall longevity and efficiency of the truck 4.

Installation Considerations

When installing the Cummins 3062158 Check Valve, it is important to follow guidelines and best practices to ensure proper integration within the system. This includes orienting the valve correctly to allow for unidirectional flow, using the appropriate tools for installation, and ensuring it is securely fastened. Integration within existing systems should be done with care to avoid disrupting other components or causing leaks.

Troubleshooting Common Issues

Frequent problems associated with check valves can include leakage, failure to open or close properly, or clogging. Diagnosing these issues may involve inspecting the valve for signs of wear or damage, checking for obstructions within the valve, or testing the system pressure to identify any anomalies. Recommended solutions or adjustments may include cleaning the valve, replacing worn components, or adjusting the system pressure to ensure proper operation.

Maintenance Tips

Routine maintenance practices for the Cummins 3062158 Check Valve can help ensure longevity and optimal performance. This may include regular inspection intervals to check for signs of wear or damage, cleaning the valve to remove any buildup or obstructions, and lubricating moving parts to ensure smooth operation. Following these maintenance tips can help prevent common issues and ensure the valve continues to operate efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications.

Role of Part 3062158 Check Valve in Engine Systems

The part 3062158 Check Valve is an essential component in maintaining the integrity and efficiency of various engine systems. Its primary function is to allow fluid or gas to flow in one direction while preventing backflow, which is vital for the consistent operation of several engine components.

Fuel System Integration

In the fuel system, the Check Valve is typically positioned between the fuel pump and the fuel injection system. It ensures that the pressurized fuel moves towards the injectors without any reverse flow. This unidirectional flow is important for maintaining the correct fuel pressure, which is necessary for the fuel injectors to atomize the fuel properly. Proper atomization ensures efficient combustion, leading to better engine performance and fuel economy.

Air Assembly and Fuel Control Cover

The Check Valve also plays a role in the air assembly by ensuring that the air-fuel mixture remains consistent. By preventing any backflow in the fuel lines, it helps maintain a stable fuel pressure that, when combined with the correct air intake, results in an optimal air-fuel ratio. This is particularly important in systems where the fuel control cover integrates with the fuel pump to regulate fuel delivery. A stable air-fuel ratio is essential for efficient combustion and reduced emissions.

Fuel Pump and Fuel Injection System

When integrated with the fuel pump, the Check Valve ensures that the pump operates under consistent conditions. By preventing fuel from flowing back into the pump, it maintains a steady pressure that allows the pump to function efficiently. This consistent pressure is then delivered to the fuel injection system, where it ensures that each injector receives the correct amount of fuel at the right time. This precision is vital for the engine’s overall performance and longevity.

Code and System Diagnostics

In modern engine systems, the Check Valve also contributes to the accuracy of diagnostic codes. By ensuring that fuel flow is consistent and unidirectional, it helps prevent false readings that could lead to incorrect diagnoses. This is particularly important in systems where the fuel pump and fuel injection are closely monitored by the engine control unit (ECU). Accurate diagnostics lead to more effective maintenance and troubleshooting, ultimately contributing to the engine’s reliability and performance.

Conclusion

The Cummins 3062158 Check Valve is a critical component in ensuring the efficient and reliable operation of commercial truck systems. By preventing backflow and maintaining consistent system pressure, it contributes to the overall performance and longevity of the truck. Proper installation, maintenance, and troubleshooting practices are essential to maximize the benefits of this valve.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.