This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3042360 Check Valve is a critical component designed for use in commercial truck systems. Its primary function is to regulate the flow of fluids, ensuring that fluid moves in the intended direction and preventing backflow. This valve is essential for maintaining the efficiency and reliability of the truck’s fluid systems.

Basic Concepts of Check Valves

Check valves are devices that allow fluid to flow in one direction while preventing flow in the opposite direction. They operate using a mechanism that opens when fluid pressure is applied in the correct direction and closes when the pressure is reversed or removed. These valves are commonly used in various fluid systems, including hydraulic, pneumatic, and fuel systems, to maintain system integrity and prevent damage from backflow 1.

Purpose of the Cummins 3042360 Check Valve

The Cummins 3042360 Check Valve ensures that fluid flows in the correct direction within the truck’s fluid systems. This valve is typically installed in systems where backflow could cause damage or reduce efficiency. By preventing reverse flow, it helps maintain system pressure and ensures that components receive the necessary fluid supply for optimal operation 2.

Key Features

The Cummins 3042360 Check Valve is characterized by several key features that enhance its performance. It is designed with precision to ensure reliable operation under various conditions. The valve is constructed from durable materials that resist corrosion and wear, ensuring longevity. Additionally, its design includes features that facilitate easy installation and maintenance, contributing to its overall effectiveness in commercial truck applications 3.

Benefits

The Cummins 3042360 Check Valve offers several advantages. It contributes to improved system efficiency by ensuring that fluid flows in the intended direction, reducing the risk of system damage from backflow. The valve’s reliable operation enhances the overall reliability of the truck’s fluid systems. Furthermore, its durable construction and design features contribute to its longevity, providing value over the truck’s operational life 4.

Installation Considerations

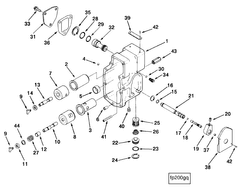

When installing the Cummins 3042360 Check Valve, it is important to follow guidelines and best practices to ensure proper function. This may include ensuring that the valve is installed in the correct orientation to allow for proper fluid flow. Special tools or prerequisites may be required for installation, depending on the specific application. Adhering to these guidelines helps ensure that the valve operates as intended within the truck’s fluid systems.

Troubleshooting Common Issues

Common problems associated with check valves can include issues with fluid flow, such as restricted flow or backflow. Diagnosing these issues may involve checking the valve for obstructions, ensuring it is installed correctly, and verifying that it operates within the system’s pressure parameters. Potential solutions can range from cleaning the valve to replacing it if it is found to be faulty.

Maintenance Tips

To ensure optimal performance of the Cummins 3042360 Check Valve, regular maintenance is recommended. This includes inspecting the valve for signs of wear or damage and cleaning it as necessary to remove any buildup that could affect its operation. Following manufacturer guidelines for maintenance intervals and procedures helps maintain the valve’s effectiveness and contributes to the overall reliability of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the commercial truck industry, providing reliable and efficient power solutions for a wide range of applications. The company’s commitment to excellence is reflected in its products, including the Cummins 3042360 Check Valve, which is designed to meet the demanding requirements of commercial truck systems.

Role of Part 3042360 Check Valve in Engine Systems

The Cummins 3042360 Check Valve is an essential component in maintaining the integrity and efficiency of fuel delivery systems within various engine setups. Its primary function is to allow fuel to flow in one direction while preventing any backflow, which ensures consistent fuel pressure and delivery.

In the context of the fuel base pump, the Check Valve is positioned to safeguard against fuel that might otherwise reflux into the pump. This protection is vital for sustaining the pump’s performance and longevity, as consistent fuel flow prevents unnecessary strain and potential damage.

When integrated with the fuel pump, the Check Valve ensures that the pressurized fuel is delivered efficiently to the engine without any loss of pressure due to backflow. This is particularly important in high-performance engines where precise fuel delivery is necessary for optimal combustion and power output.

In the fuel injection system, the Check Valve plays a role in maintaining the required fuel pressure within the rails. This ensures that each injector receives a consistent amount of fuel, which is essential for the precise control of fuel delivery and the overall efficiency of the injection process.

For the fuel base and associated components, the Check Valve helps in stabilizing the fuel supply. This stability is crucial for the reliable operation of the fuel system, especially under varying engine loads and conditions.

Conclusion

In summary, the Cummins 3042360 Check Valve is a key element in ensuring that fuel systems operate smoothly and efficiently. By preventing backflow and maintaining consistent fuel pressure, it supports the reliable performance of pumps, injectors, and other fuel system components.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.