This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

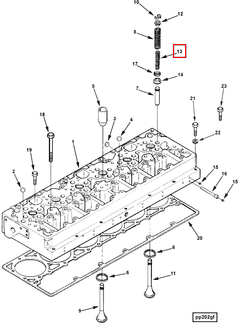

The Valve Spring 3033233 by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to ensure the proper operation of the engine’s valve train system, which is vital for the overall performance and efficiency of the vehicle. This valve spring is engineered to withstand the demanding conditions encountered in heavy-duty applications, providing reliable valve actuation and contributing to the engine’s durability and performance 1.

Basic Concepts of Valve Springs

Valve springs are mechanical components found in internal combustion engines. Their primary function is to maintain contact between the valve and the valve seat when the valve is closed, ensuring a proper seal is formed to prevent the escape of combustion gases. During engine operation, the camshaft opens the valves by pushing against the valve stem. Once the camshaft lobe moves away, the valve spring returns the valve to its closed position. This cyclical action is essential for the intake and exhaust processes in the engine 2.

Role of Valve Spring 3033233 in Truck Operation

The Valve Spring 3033233 plays a significant role in the engine’s valve train system of heavy-duty trucks. It is responsible for returning the valve to its closed position after being opened by the camshaft. This ensures that the valve seals properly against the valve seat, which is important for maintaining compression within the combustion chamber and for efficient exhaust gas evacuation. The performance of this valve spring directly influences engine efficiency, power output, and fuel consumption 3.

Key Features of Valve Spring 3033233

The Valve Spring 3033233 is characterized by several distinctive features that enhance its performance. It is constructed from high-quality materials that offer superior strength and durability under high stress and temperature conditions. The design of the spring includes specific winding techniques that provide optimal spring rate and durability. Additionally, the spring may feature unique end configurations to ensure proper seating and reduce the risk of valve float at high engine speeds 4.

Benefits of Using Valve Spring 3033233

Incorporating the Valve Spring 3033233 into heavy-duty truck engines offers several advantages. Its robust construction and precise engineering contribute to increased durability and reliability, reducing the likelihood of valve train failures. The spring’s design also enhances engine performance by ensuring consistent valve operation, which can lead to improvements in horsepower, torque, and fuel efficiency 5.

Installation and Maintenance Guidelines

Proper installation of the Valve Spring 3033233 is important to ensure optimal performance and longevity. It should be installed according to the manufacturer’s specifications, with attention to correct orientation and seating. Regular maintenance, including periodic inspection for signs of wear or damage, is recommended to prevent potential issues. Maintenance practices should align with the manufacturer’s guidelines to ensure the spring continues to function effectively throughout the engine’s operational life 6.

Troubleshooting Common Issues

Typical problems associated with valve springs include spring breakage, loss of tension, and valve float. These issues can be diagnosed through visual inspection, performance testing, and analysis of engine symptoms such as misfires or loss of power. Recommended solutions may involve spring replacement, adjustment of valve clearances, or addressing underlying causes such as camshaft wear or improper installation 7.

Performance Enhancements

The Valve Spring 3033233 contributes to overall engine performance by ensuring precise and reliable valve actuation. This can result in potential improvements in horsepower and torque output, as well as enhanced fuel efficiency. The spring’s ability to maintain valve seal integrity under varying engine conditions is key to achieving these performance benefits 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications 9.

Conclusion

The Valve Spring 3033233 by Cummins is a critical component in the engine’s valve train system, ensuring efficient and reliable operation in heavy-duty truck engines. Its robust construction, precise engineering, and role in maintaining valve operation contribute to the engine’s durability, performance, and efficiency. Proper installation and maintenance are essential to maximize the benefits of this Cummins part.

-

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Reif, K. Ed. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5504366.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5504366.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5504366.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5504366.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.