This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Valve Spring Retainer, specifically Part #3028216 by Cummins, is a component that plays a significant role in the operation of heavy-duty truck engines. Cummins Inc., a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation in engine technology. This part is part of Cummins’ extensive range of engine components designed to enhance the performance and reliability of heavy-duty trucks.

Basic Concepts of Valve Spring Retainers

A Valve Spring Retainer is a mechanical component used in internal combustion engines. Its primary function is to keep the valve spring compressed and in place on the valve stem. This ensures that the valve operates correctly by maintaining consistent pressure on the valve throughout its operation cycle. The retainer interacts closely with other components such as valve springs and valves, ensuring that the valve opens and closes at the correct times and with the appropriate force 1.

Role of the Valve Spring Retainer in Truck Engine Operation

The Valve Spring Retainer plays a role in maintaining valve operation by ensuring that the valve spring remains properly positioned on the valve stem. This is crucial for the valve to open and close efficiently, which in turn affects the engine’s ability to intake air and expel exhaust gases. Proper valve operation is fundamental to engine efficiency and performance, as it directly influences the combustion process. The retainer contributes to maintaining the valve’s seal against the cylinder head, which is vital for preventing leaks that could reduce engine efficiency 2.

Key Features of the Cummins Valve Spring Retainer (Part #3028216)

The Cummins Valve Spring Retainer (Part #3028216) is designed with specific characteristics that enhance its durability and performance. It is constructed from high-quality materials that can withstand the high temperatures and pressures present in heavy-duty truck engines. The design of the retainer includes features that improve its ability to maintain a secure hold on the valve spring, even under extreme operating conditions. These features contribute to the overall reliability and longevity of the component 3.

Benefits of Using the Cummins Valve Spring Retainer

Utilizing the Cummins Valve Spring Retainer offers several advantages. The retainer’s robust design and material quality contribute to improved engine reliability, ensuring that the valve system operates smoothly under a wide range of conditions. Enhanced performance is another benefit, as the retainer helps maintain optimal valve operation, which is crucial for efficient combustion and engine output. Additionally, the durability of the Cummins retainer can lead to potential cost savings over time, as it may require less frequent replacement compared to other brands.

Troubleshooting and Maintenance Suggestions

Identifying common issues related to Valve Spring Retainers can help in maintaining engine performance. Symptoms such as engine misfires, reduced power, or unusual noises from the engine compartment may indicate problems with the valve system, including the retainer. Regular maintenance practices, such as inspecting the retainer for signs of wear or damage during routine engine checks, can help prevent issues. If replacement or repair is necessary, following the manufacturer’s guidelines ensures that the component is installed correctly and functions as intended.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the heavy-duty truck industry. The company’s commitment to advancing technology and improving engine performance is evident in its product offerings, including the Valve Spring Retainer (Part #3028216). Cummins continues to lead the industry with its focus on sustainability, efficiency, and customer satisfaction.

Compatibility of Valve Spring Retainer (Part 3028216) with Cummins Engines

The Valve Spring Retainer part number 3028216, manufactured by Cummins, is designed to ensure the proper operation of the valve train in various Cummins engines. This part is designed to securely hold the valve springs in place, preventing any movement that could lead to engine performance issues or failure.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Valve Spring Retainer 3028216 plays a pivotal role in maintaining the integrity of the valve train system. Given the robust nature of the N14 MECHANICAL engines, this part must withstand high levels of stress and pressure, ensuring that the valve springs remain firmly in position during the engine’s operation.

NH/NT 855 Engines

For the NH/NT 855 engines, the Valve Spring Retainer 3028216 is equally essential. These engines are known for their reliability and efficiency, and the proper functioning of the valve train is crucial for maintaining these characteristics. The retainer ensures that the valve springs are held securely, contributing to the smooth and efficient operation of the engine.

V28 Engines

The V28 engines also benefit from the use of the Valve Spring Retainer 3028216. This part is integral to the valve train system, ensuring that the valve springs are kept in place under the demanding conditions these engines operate under. The V28 engines are designed for heavy-duty applications, and the retainer’s role in maintaining valve train integrity is vital for the engine’s performance and longevity.

By ensuring that the valve springs remain securely in place, the Valve Spring Retainer 3028216 contributes to the overall reliability and efficiency of these Cummins engines. This part is a testament to Cummins’ commitment to quality and durability in their engine components.

Role of Part 3028216 Valve Spring Retainer in Engine Systems

The part 3028216 Valve Spring Retainer is an integral component within the engine’s valve train system. It is specifically designed to secure the valve spring in place, ensuring that the spring remains correctly positioned over the valve stem. This retention is essential for the proper functioning of the valve, as it allows the spring to effectively control the opening and closing of the valve.

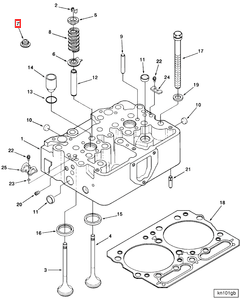

In the context of the cylinder head, the Valve Spring Retainer works in conjunction with other components such as the valve spring, valve stem, and valve keeper. The cylinder head houses the combustion chamber and the valve mechanisms, and the precise operation of these mechanisms is dependent on the secure placement of the valve spring. The Retainer ensures that the spring applies consistent pressure to the valve, enabling it to seal the combustion chamber during the compression and combustion phases and to open at the correct time to allow the intake and exhaust of gases.

When considering performance parts such as those offered by EBM Performance Parts, the Valve Spring Retainer plays a significant role in enhancing engine performance. High-performance engines often require stronger valve springs to handle increased valvetrain stresses at higher RPMs. The Retainer must be robust enough to withstand these increased stresses while maintaining the integrity of the valve spring’s position.

The interaction between the Valve Spring Retainer and the fuel code is indirect but still significant. The fuel code dictates the engine’s fuel delivery and ignition timing, which are influenced by the efficiency and timing of valve operation. A well-retained valve spring ensures that the valves open and close at the precise moments required by the fuel code, optimizing combustion efficiency and power output.

Conclusion

In summary, the part 3028216 Valve Spring Retainer is a key component that ensures the reliable operation of the valve spring within the engine’s valve train system. Its proper function is essential for maintaining the integrity of the valve’s operation, which in turn affects the engine’s overall performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.