5413789

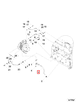

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5413789 Turbocharger Oil Drain Connection is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. Its purpose is to ensure that the turbocharger operates efficiently by maintaining proper lubrication and preventing oil buildup, which can lead to performance issues. This component is significant in the operation of heavy-duty trucks as it contributes to the overall reliability and longevity of the turbocharger and engine system 3.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the turbocharger system, allowing for the periodic removal of oil that has lubricated the turbocharger’s moving parts. This process is vital for maintaining the health of the turbocharger, as it prevents the accumulation of contaminants and degraded oil, which can impair performance and lead to premature wear 1. The oil drain connection works in conjunction with the turbocharger’s oil management system to ensure that fresh oil is circulated while used oil is efficiently drained away.

Purpose of the 5413789 Turbocharger Oil Drain Connection

The 5413789 Turbocharger Oil Drain Connection plays a specific role in the operation of a truck’s engine by providing a means to drain oil from the turbocharger. This function is part of the oil management system, which ensures that the turbocharger remains properly lubricated without excess oil that could lead to inefficiencies or damage. By facilitating the drainage of used oil, this component helps maintain optimal turbocharger performance and extends the lifespan of the turbocharger and associated engine components 3.

Key Features

The 5413789 Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability. Its design incorporates robust materials that can withstand the high temperatures and pressures within the turbocharger environment. Additionally, the connection is engineered to provide a secure seal, preventing oil leaks that could compromise engine performance. Unique characteristics such as corrosion-resistant coatings and precision machining contribute to its reliability and effectiveness in demanding applications 1.

Benefits

Utilizing the 5413789 Turbocharger Oil Drain Connection offers several benefits. It contributes to improved turbocharger efficiency by ensuring that the turbocharger operates with the correct amount of lubrication. This, in turn, can lead to extended component lifespan, as proper oil management reduces wear on turbocharger parts. Furthermore, the enhanced overall engine performance resulting from a well-maintained turbocharger can improve fuel efficiency and reduce emissions, contributing to a more environmentally friendly operation 3.

Installation Process

Installing the 5413789 Turbocharger Oil Drain Connection requires following a step-by-step procedure to ensure proper integration into the turbocharger system. The process involves preparing the turbocharger for installation, aligning the drain connection with the designated port, and securing it in place using the appropriate tools. Precautions such as ensuring the turbocharger is clean and free of debris, and verifying that all connections are tight and secure, are important to prevent oil leaks and ensure optimal performance. Best practices include referring to the manufacturer’s installation guidelines and performing a system check post-installation to confirm proper operation 1.

Troubleshooting Common Issues

Common problems that may arise with the 5413789 Turbocharger Oil Drain Connection include oil leaks, difficulty in draining oil, and connection failure. Troubleshooting these issues involves inspecting the connection for signs of wear or damage, ensuring that it is properly aligned and secured, and checking for any obstructions in the oil drainage path. Solutions may include tightening or replacing the connection, cleaning the turbocharger and associated components, and verifying that the oil management system is functioning correctly 2.

Maintenance Tips

Routine maintenance practices are crucial for keeping the 5413789 Turbocharger Oil Drain Connection in optimal condition. This includes regular inspection intervals to check for signs of wear, corrosion, or leaks. Cleaning procedures should be performed to remove any buildup of contaminants around the connection, and lubrication guidelines should be followed to ensure that all moving parts within the turbocharger system remain properly lubricated. Adhering to these maintenance tips will help ensure the longevity and efficiency of the turbocharger oil drain connection 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company’s product offerings are designed to meet the demanding requirements of various applications, providing customers with efficient, durable, and environmentally responsible power solutions 3.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection part number 5413789 is a critical component in the maintenance and operation of several Cummins engines. This part is integral to the engine’s lubrication system, ensuring that oil is properly drained from the turbocharger. Below is a detailed look at how this part fits within specific Cummins engines.

ISX CM871

In the ISX CM871 engine, the Turbocharger Oil Drain Connection part number 5413789 plays a vital role in maintaining the health of the turbocharger. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The turbocharger oil drain connection ensures that any excess oil is efficiently removed from the turbocharger, preventing oil buildup that could lead to overheating and potential damage 3.

Grouping of Engines

While the Turbocharger Oil Drain Connection part number 5413789 is specifically designed for the ISX CM871, it is also compatible with other Cummins engines that share similar design and lubrication requirements. This part is engineered to fit seamlessly into the engine’s system, ensuring that oil is properly managed and drained from the turbocharger.

The use of this part in Cummins engines underscores the manufacturer’s commitment to providing high-quality, reliable components that enhance engine performance and longevity 3.

Role of Part 5413789 Turbocharger Oil Drain Connection in Engine Systems

The Part 5413789 Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This part facilitates the necessary oil drainage from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters 3.

Integration with Turbocharger Systems

In turbocharger systems, the oil drain connection plays a significant role in managing the lubrication circuit. Turbochargers rely on a continuous supply of oil to lubricate their bearings and maintain cooling. As oil circulates through the turbocharger, it picks up heat and contaminants. The oil drain connection allows for the regular removal of this used oil, which is then replaced with fresh oil to maintain lubrication efficiency and prevent buildup of contaminants 1.

Interaction with Plumbing Systems

The oil drain connection is also a key interface within the engine’s plumbing system. It connects to the oil return lines, which transport the used oil back to the sump or oil pan. This ensures that the oil can be filtered and recirculated, maintaining the overall health of the engine’s lubrication system. Proper integration of the oil drain connection with the plumbing ensures that there are no leaks and that the oil flow is uninterrupted, which is vital for the longevity and performance of the turbocharger and the engine as a whole 1.

Maintenance and Operational Efficiency

Regular maintenance of the oil drain connection is important to prevent issues such as oil leaks or blockages, which can lead to turbocharger failure. Engineers and mechanics must ensure that the connection is securely fitted and that there are no signs of wear or damage. This part’s role in facilitating easy drainage and maintenance makes it a valuable component in the overall turbocharger system 2.

Conclusion

In summary, the Part 5413789 Turbocharger Oil Drain Connection is integral to the efficient operation and maintenance of turbocharger systems. Its proper function ensures that the turbocharger remains well-lubricated and cool, contributing to the overall performance and reliability of the engine 3.

-

Ben Watson, Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Cengage Learning, 2011.

↩ ↩ ↩ ↩ ↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE Books, 2023.

↩ ↩ -

Konrad Reif, Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Springer Vieweg, 2014.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.