4936158

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #4936158, is a component manufactured by Cummins. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Cummins, a renowned name in diesel engine manufacturing, ensures that this component meets high standards of quality and performance 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that enhance engine performance by compressing the air entering the engine, allowing for more fuel to be burned and thus generating more power. Oil lubrication plays a vital role in the operation of turbochargers, reducing friction and wear on moving parts. The oil drain connection is a critical component in this system, designed to allow for the periodic removal of oil from the turbocharger. This process is important for maintaining the efficiency and longevity of the turbocharger, as it ensures that the oil remains clean and free of contaminants that could otherwise impair performance 2.

Purpose and Function

The Turbocharger Oil Drain Connection serves a specific role in the operation of a truck’s engine. It facilitates the draining of oil from the turbocharger, which is a necessary maintenance procedure to ensure the turbocharger operates at peak efficiency. By allowing for the easy removal of oil, this component helps in maintaining the optimal performance and longevity of the turbocharger. Regular oil changes are important for preventing the buildup of contaminants that could lead to increased wear and reduced efficiency 3.

Key Features

The Turbocharger Oil Drain Connection is designed with several features that enhance its functionality and durability. Constructed from high-quality materials, it is built to withstand the harsh conditions within a heavy-duty truck engine. Its design ensures a secure connection, preventing leaks and ensuring that oil is effectively drained from the turbocharger. Additionally, the connection is engineered to be compatible with Cummins turbochargers, ensuring seamless integration into the engine system 4.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It simplifies the process of turbocharger maintenance, allowing for more efficient oil changes. This, in turn, contributes to enhanced engine performance, as clean oil is important for the optimal operation of the turbocharger. Furthermore, by facilitating regular maintenance, this component plays a role in increasing the reliability of the truck’s engine system, potentially reducing downtime and maintenance costs 5.

Troubleshooting and Maintenance

Common issues associated with turbocharger oil drain connections include leaks and blockages. Regular inspections are important for identifying these problems early, allowing for timely repairs or replacements. Maintenance practices should include checking the connection for signs of wear or damage, ensuring that it remains securely attached, and following manufacturer guidelines for oil change intervals. Proper maintenance of the oil drain connection is important for ensuring the longevity and efficiency of the turbocharger 6.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a leader in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in diesel engine manufacturing is evident in its range of products, which are designed to meet the demanding requirements of heavy-duty applications 7.

Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection part number 4936158, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral to the engine’s lubrication system, ensuring that oil is properly drained from the turbocharger, thereby maintaining optimal performance and longevity of the turbocharger components.

ISB CM2150 and ISB6.7 CM2250

The Turbocharger Oil Drain Connection part 4936158 is compatible with both the ISB CM2150 and ISB6.7 CM2250 engines. These engines are part of Cummins’ lineup of high-performance, reliable diesel engines, known for their efficiency and durability. The part ensures that the oil used to lubricate the turbocharger is effectively drained, preventing oil accumulation that could lead to overheating and potential damage.

ISB6.7 CM2350 B101

Similarly, the Turbocharger Oil Drain Connection part 4936158 is also designed to fit the ISB6.7 CM2350 B101 engine. This engine is an advanced model in Cummins’ ISB series, offering enhanced power and efficiency. The part’s compatibility with this engine ensures that the turbocharger’s oil is drained efficiently, maintaining the engine’s performance and reliability.

Grouping of Engines

The Turbocharger Oil Drain Connection part 4936158 is engineered to fit within the Cummins ISB engine family, which includes the ISB CM2150, ISB6.7 CM2250, and ISB6.7 CM2350 B101 models. This grouping is based on the shared design and engineering principles of these engines, ensuring that the part fits and functions correctly across the specified models.

Role of Part 4936158 Turbocharger Oil Drain Connection in Engine Systems

The turbocharger oil drain connection, identified by part number 4936158, is an essential component in the turbocharger plumbing system of an engine. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system operates efficiently.

Integration with Turbocharger Plumbing

-

Oil Circulation System: The turbocharger oil drain connection is integral to the oil circulation system within the turbocharger. It allows for the periodic removal of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This ensures that fresh oil is consistently supplied, maintaining optimal lubrication and reducing wear.

-

Drainage Mechanism: Positioned at a low point in the turbocharger’s oil system, the drain connection enables the collection of oil that has circulated through the system. This oil, which may contain contaminants and wear particles, is then directed back to the engine’s oil sump for filtration and recirculation.

-

Maintenance Access: The turbocharger oil drain connection provides a convenient access point for maintenance procedures. Technicians can easily drain the oil from the turbocharger without disassembling the entire system, simplifying routine maintenance and reducing downtime.

-

System Pressure Management: By allowing the controlled release of oil, the drain connection helps manage system pressures within the turbocharger. This is particularly important during engine shutdown, when residual pressure in the oil system needs to be safely dissipated to prevent damage to seals and other components.

-

Compatibility with Sensors and Monitoring Systems: In modern engine systems, the turbocharger oil drain connection may also interface with sensors that monitor oil quality and system health. This integration allows for real-time data collection on oil condition, enabling predictive maintenance and ensuring the turbocharger operates within specified parameters.

Conclusion

In summary, the turbocharger oil drain connection (part 4936158) plays a significant role in maintaining the efficiency and reliability of the turbocharger plumbing system. Its proper function ensures effective oil management, facilitates maintenance, and contributes to the overall performance of the engine.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

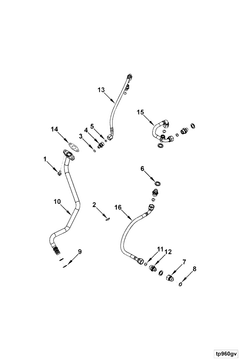

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3928624 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.