This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

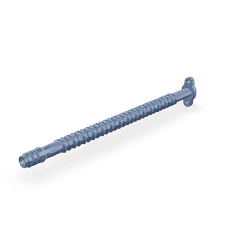

The Cummins 4932490 Turbo Oil Drain Tube is designed to facilitate the efficient drainage of oil from the turbocharger in heavy-duty trucks. This part ensures proper oil management within the turbocharger system, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Turbo Oil Drain Tubes

Turbo oil drain tubes are integral to the turbocharger system, allowing excess oil to be drained from the turbocharger. This process is vital for maintaining the lubrication system’s efficiency and preventing oil buildup, which could lead to performance issues or damage 1. The drain tube ensures that any surplus oil is returned to the sump, maintaining the correct oil level and pressure within the turbocharger.

Purpose and Function

The Cummins 4932490 Turbo Oil Drain Tube is designed to facilitate the drainage of oil from the turbocharger. It ensures that oil used for lubricating the turbocharger’s moving parts is efficiently returned to the engine’s oil sump. This process helps maintain the turbocharger’s operational temperature, reducing the risk of overheating and ensuring that the turbocharger operates within its designed parameters 2.

Key Features

The Turbo Oil Drain Tube is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. Its construction is tailored to withstand the high pressures and temperatures associated with turbocharger operation. The tube’s design ensures a secure fit within the turbocharger system, minimizing the risk of leaks and ensuring efficient oil drainage.

Benefits

Utilizing the Cummins 4932490 Turbo Oil Drain Tube offers several advantages. It contributes to improved turbocharger performance by ensuring efficient oil management. This, in turn, enhances engine reliability by reducing the risk of turbocharger-related issues. Additionally, the tube’s design and functionality can lead to potential cost savings through reduced maintenance needs, as it helps maintain the turbocharger’s optimal condition over time 3.

Installation Process

Installing the Cummins 4932490 Turbo Oil Drain Tube requires careful attention to ensure proper fitting and functionality. The process involves securing the tube within the turbocharger system, ensuring all connections are tight and leak-free. It is important to follow manufacturer guidelines for installation to ensure the tube operates as intended. Tools and equipment required may include wrenches for securing connections and possibly a torque wrench to ensure bolts are tightened to the specified torque.

Maintenance and Troubleshooting

Maintaining the Cummins 4932490 Turbo Oil Drain Tube involves regular inspection to ensure it remains in good condition and functions correctly. Common issues may include leaks or blockages, which can be addressed through routine checks and cleaning. Troubleshooting tips include verifying connections are secure, ensuring there are no obstructions in the tube, and checking for signs of wear or damage that may affect its performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company’s product range includes engines for on-highway, off-highway, and power generation applications, demonstrating its commitment to providing reliable and efficient power solutions across various industries.

Turbo Oil Drain Tube for Cummins Engines

The Turbo Oil Drain Tube, part number 4932490, is a critical component in the maintenance and operation of certain Cummins engines. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the system remains clean and free from contaminants that could lead to performance issues or damage.

Application in Cummins Engines

The Turbo Oil Drain Tube is compatible with a range of Cummins engines, including but not limited to, the 4B3.9 engine. This part is essential in maintaining the efficiency and longevity of the turbocharger by allowing the oil to be drained out effectively. The design of the tube ensures that it fits seamlessly with the engine’s architecture, providing a reliable pathway for oil to exit the turbocharger.

Grouping of Compatible Engines

While the Turbo Oil Drain Tube is specifically mentioned for the 4B3.9 engine, it is also applicable to other Cummins engines within the same family or those that share similar design characteristics. This includes engines that are part of the same production line or those that have been engineered to use interchangeable parts. The compatibility extends to engines that have been designed with similar maintenance requirements and specifications.

Importance of the Turbo Oil Drain Tube

The Turbo Oil Drain Tube plays a vital role in the overall health of the engine. By ensuring that the turbocharger is free from excess oil, it helps to prevent oil from entering the combustion chamber, which can lead to increased emissions and reduced engine efficiency. Additionally, the proper drainage of oil helps to maintain the correct oil levels within the turbocharger, which is crucial for its optimal performance.

Installation and Maintenance

When installing the Turbo Oil Drain Tube, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be performed to verify that the tube is not clogged or damaged, as this could impede the oil drainage process and lead to potential engine issues. Replacement of the tube should be considered if any signs of wear or damage are detected.

Role of Part 4932490 Turbo Oil Drain Tube in Engine Systems

The Turbo Oil Drain Tube, part 4932490, is an essential component in the maintenance and operation of turbocharged engine systems. Its primary function is to facilitate the efficient drainage of oil from the turbocharger, ensuring that the lubrication system remains clean and free from contaminants.

Integration with Turbocharger

In turbocharged engines, the turbocharger operates at extremely high speeds and temperatures. This intense environment necessitates a robust lubrication system to maintain the turbocharger’s bearings and other moving parts. The Turbo Oil Drain Tube is strategically positioned to connect the turbocharger to the engine’s oil return system. This connection allows for the continuous circulation of oil, which is vital for cooling and lubricating the turbocharger.

Interaction with Plumbing

The Turbo Oil Drain Tube is part of the engine’s plumbing system, which includes a network of hoses, pipes, and fittings designed to manage the flow of fluids. The tube is typically connected to the turbocharger’s oil feed line and the oil return line. This setup ensures that used oil is efficiently drained back into the sump, where it can be filtered and recirculated. The proper installation of the Turbo Oil Drain Tube is essential to prevent oil leaks and maintain system integrity.

Maintenance and Efficiency

Regular maintenance of the Turbo Oil Drain Tube is necessary to ensure the turbocharger operates efficiently. Over time, the tube may become clogged with debris or develop leaks, which can lead to oil starvation in the turbocharger. By facilitating the smooth drainage of oil, the Turbo Oil Drain Tube helps maintain optimal turbocharger performance and extends the lifespan of the turbocharger and associated components.

Conclusion

The Cummins 4932490 Turbo Oil Drain Tube plays a significant role in the turbocharged engine system by ensuring efficient oil drainage, maintaining lubrication, and supporting the overall performance and reliability of the turbocharger. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.