This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

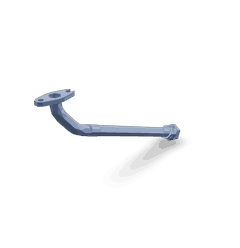

The Turbocharger Oil Drain Connection (4921913) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. This part ensures that oil does not accumulate within the turbocharger, which could lead to inefficiencies and potential damage. Its role is significant in maintaining the optimal performance and longevity of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the turbocharger system. They allow for the periodic removal of oil that has lubricated the turbocharger’s moving parts. This process helps prevent oil buildup, which can cause increased temperatures and reduced efficiency. The drain connection is typically located at the lowest point of the turbocharger to ensure that oil can be effectively removed 1.

Role of the Turbocharger Oil Drain Connection

The 4921913 Turbocharger Oil Drain Connection plays a specific role in the operation of a truck’s engine by providing a pathway for oil to be drained from the turbocharger. This part interacts with the turbocharger’s lubrication system, ensuring that excess oil is expelled regularly. Proper drainage helps maintain the turbocharger’s efficiency and prevents oil-related issues that could affect engine performance 2.

Key Features

The 4921913 Turbocharger Oil Drain Connection is characterized by several key features that enhance its functionality and durability. Its design incorporates a secure fitting that ensures a tight seal, preventing oil leaks. The material used is resistant to high temperatures and corrosion, ensuring longevity in harsh operating conditions. The construction is robust, capable of withstanding the pressures and vibrations inherent in heavy-duty truck engines 3.

Benefits

The 4921913 Turbocharger Oil Drain Connection offers several benefits. It contributes to improved engine performance by ensuring that the turbocharger operates efficiently without excess oil. This part enhances the reliability of the engine by preventing oil-related issues that could lead to turbocharger failure. Additionally, it simplifies maintenance by providing an easy-to-use drain point, reducing the time and effort required for oil drainage.

Installation Process

Installing the 4921913 Turbocharger Oil Drain Connection involves several steps. First, ensure the engine is cool and the turbocharger is free of pressure. Locate the drain connection on the turbocharger and connect the provided drain line to the connection. Use the appropriate tools to secure the fitting, ensuring a tight seal. Finally, perform a visual inspection to confirm there are no leaks and that the connection is properly installed.

Maintenance Tips

Regular maintenance of the 4921913 Turbocharger Oil Drain Connection is crucial for its longevity and optimal performance. Inspect the connection regularly for signs of wear or damage. Ensure that the fitting remains secure and that there are no leaks. Drain the oil at recommended intervals to prevent buildup. Keep the area around the connection clean to avoid contamination.

Troubleshooting Common Issues

Common issues with the 4921913 Turbocharger Oil Drain Connection may include leaks or blockages. If a leak is detected, inspect the fitting for proper tightness and ensure there is no damage to the connection. For blockages, check the drain line for obstructions and clear any debris. Regular maintenance can help prevent these issues.

Safety Considerations

When working with the 4921913 Turbocharger Oil Drain Connection, it is important to observe several safety guidelines. Ensure the engine is cool before attempting any maintenance or installation. Use appropriate personal protective equipment, such as gloves and safety glasses. Follow all manufacturer recommendations for tools and procedures to prevent accidents and ensure safe operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its high-quality products and innovative solutions in the heavy-duty truck industry. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the field.

Turbocharger Oil Drain Connection for ISM CM876 Engines

The Turbocharger Oil Drain Connection part number 4921913, manufactured by Cummins, is a critical component in the ISM CM876 engine series. This part is integral to the engine’s lubrication system, ensuring that the turbocharger is adequately supplied with oil while also facilitating the drainage of used oil back to the sump.

In the ISM CM876 engine family, the turbocharger oil drain connection is designed to interface seamlessly with the engine’s oil supply and return lines. This ensures that the turbocharger receives a consistent flow of oil for lubrication and cooling purposes. The connection is engineered to withstand the high pressures and temperatures typically encountered in the engine’s operating environment, ensuring reliability and longevity.

The part number 4921913 is specifically tailored to fit the ISM CM876 engines, which are known for their robust performance and efficiency. Cummins has ensured that this turbocharger oil drain connection is compatible with the unique design and specifications of the ISM CM876 engines, providing a precise fit and optimal functionality.

Role of Part 4921913 Turbocharger Oil Drain Connection in Engine Systems

The Part 4921913 Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharged engine systems. This component facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

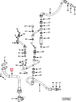

Integration with Turbocharger

In turbocharged engines, the turbocharger relies on a steady supply of oil for lubrication and cooling. The Turbocharger Oil Drain Connection allows for the periodic removal of used oil, which can become contaminated with particles and degrade over time. This process is vital for maintaining the turbocharger’s performance and longevity. The connection point is typically located at the lower part of the turbocharger housing, allowing gravity to assist in the drainage process.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines, filters, and the oil sump. When the drain connection is opened, oil flows through designated pathways back into the sump or a collection container. This ensures that the oil can be properly disposed of or recycled, depending on the maintenance protocol. The plumbing system must be designed to handle the flow rates and pressures associated with oil drainage, ensuring that no leaks occur and that the system remains sealed when not in use.

Maintenance Procedures

During routine maintenance, mechanics will use the Turbocharger Oil Drain Connection to perform oil changes. This involves disconnecting the drain line, allowing the oil to flow out, and then reconnecting the line once the drainage is complete. Proper sealing and reconnection are imperative to prevent oil leaks, which can lead to decreased lubrication efficiency and potential engine damage.

System Efficiency

Efficient drainage through the Turbocharger Oil Drain Connection contributes to the overall efficiency of the engine system. By ensuring that fresh, clean oil is circulated through the turbocharger, the risk of wear and tear is minimized. This, in turn, helps maintain the engine’s performance and extends the lifespan of both the turbocharger and the engine itself.

Conclusion

The 4921913 Turbocharger Oil Drain Connection is a meticulously designed component that plays a vital role in maintaining the health and performance of turbocharged engine systems. Its compatibility with engines like the ISM CM876 underscores Cummins’ commitment to providing high-quality, reliable parts for their engine lineup. Regular maintenance and proper installation of this part are crucial for ensuring the longevity and efficiency of the engine system.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.