This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

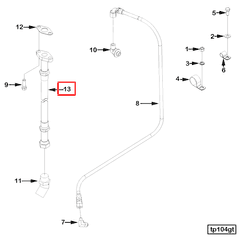

The Turbocharger Oil Drain Connection, identified by Part #4914582, is a component manufactured by Cummins, a leading name in diesel engine technology. This part is integral to the maintenance and operation of turbochargers in heavy-duty truck engines. Its role is to facilitate the draining of used oil from the turbocharger, ensuring that the lubrication system remains efficient and the turbocharger operates within optimal parameters.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connection, it is important to first grasp the fundamentals of turbochargers. Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This compression is achieved through a turbine driven by the engine’s exhaust gases.

Oil lubrication is vital for the operation of turbochargers. It reduces friction between moving parts, dissipates heat, and helps to seal the clearances between the turbine and compressor wheels. Proper lubrication is essential for the longevity and performance of the turbocharger 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It allows for the periodic draining of used oil from the turbocharger. This process is important for several reasons: it removes contaminants that may have accumulated in the oil, it ensures that fresh oil is circulated, and it helps maintain the efficiency of the lubrication system. By facilitating the draining process, this connection plays a role in preserving the turbocharger’s performance and extending its operational life.

Key Features

The design and construction of the Turbocharger Oil Drain Connection are tailored to meet the demanding requirements of heavy-duty applications. It is typically made from durable materials that can withstand high temperatures and pressures. The connection type is designed to ensure a secure fit, preventing leaks and ensuring that the draining process is efficient. Unique attributes may include anti-corrosion coatings and precision-machined surfaces to enhance performance and durability.

Benefits

Incorporating the Turbocharger Oil Drain Connection into the turbocharger system offers several advantages. It contributes to improved turbocharger longevity by ensuring that the lubrication system operates efficiently. Enhanced engine performance is another benefit, as well-lubricated turbochargers can operate more effectively. Additionally, the connection simplifies maintenance procedures by providing a straightforward method for draining used oil, reducing downtime and facilitating regular maintenance checks.

Installation Process

Proper installation of the Turbocharger Oil Drain Connection is important for its effective function. The process involves several steps: first, ensuring that the turbocharger is cool and the engine is off to prevent any injury or damage. Next, the old connection, if present, should be removed carefully. The new Turbocharger Oil Drain Connection should then be fitted, ensuring a secure and leak-free connection. Tools required may include wrenches and possibly a torque wrench to ensure proper tightening. It is important to follow manufacturer guidelines to ensure correct fitting and function.

Troubleshooting Common Issues

Typical problems associated with the Turbocharger Oil Drain Connection may include leaks or blockages. Leaks can often be traced to improper installation or wear and tear on the connection. Blockages may occur due to contaminants in the oil or debris within the system. Diagnostic procedures involve inspecting the connection for signs of wear, ensuring it is securely fitted, and checking for any obstructions in the oil drain path. Repair may involve cleaning the connection, replacing gaskets or seals, or in some cases, replacing the connection itself.

Maintenance Tips

Regular maintenance of the Turbocharger Oil Drain Connection is important to ensure it remains in optimal condition. This includes periodic inspection for signs of wear or damage, ensuring that the connection remains secure, and cleaning as necessary to remove any buildup of contaminants. Inspection intervals should be in line with the manufacturer’s recommendations or based on the operating conditions of the vehicle. Adhering to these practices helps to prolong the life of the turbocharger and maintain engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the diesel engine and component manufacturing industry. The company’s commitment to advancing technology and meeting the needs of its customers is evident in its extensive product line and ongoing research and development efforts.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection part number 4914582, manufactured by Cummins, is a critical component in the lubrication system of certain Cummins engines. This part ensures that oil is properly drained from the turbocharger, maintaining optimal performance and longevity of the turbocharger and engine.

NH/NT 855 Engines

The NH/NT 855 engines are part of the Cummins engine family that benefit from the Turbocharger Oil Drain Connection part 4914582. This part is integral to the engine’s lubrication system, facilitating the removal of oil from the turbocharger. Proper oil drainage is essential to prevent oil accumulation, which can lead to excessive wear and potential failure of the turbocharger.

The Turbocharger Oil Drain Connection part 4914582 is designed to fit seamlessly into the NH/NT 855 engines, ensuring a reliable and efficient oil drainage system. This part is engineered to meet the specific requirements of these engines, providing a secure and leak-free connection that is crucial for maintaining engine health.

Role of Part 4914582 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 4914582) is an essential component in the maintenance and operation of turbocharged engine systems. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger relies on a steady supply of oil for lubrication of its bearings and other moving parts. Over time, this oil can become contaminated with soot and other particles, which can impair its lubricating properties. The Turbocharger Oil Drain Connection allows for the periodic removal of this used oil, ensuring that fresh, clean oil is always available for lubrication. This helps in maintaining the turbocharger’s efficiency and longevity.

Connection to Plumbing Systems

The Turbocharger Oil Drain Connection is typically integrated into the engine’s plumbing system. This involves connecting it to the oil return lines that lead back to the oil sump or the oil filtration system. By doing so, the drained oil is efficiently routed away from the turbocharger and back into the engine’s oil circulation system, where it can be filtered and re-used. This closed-loop system ensures that oil is conserved and that the engine’s lubrication system remains balanced.

Maintenance and Operational Benefits

Regular use of the Turbocharger Oil Drain Connection is beneficial for several reasons. It helps in preventing the build-up of contaminants within the turbocharger, which can lead to increased wear and potential failure. Additionally, by ensuring that the oil remains clean, the turbocharger can operate more efficiently, contributing to better overall engine performance.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part 4914582) plays a significant role in the maintenance and operational efficiency of turbocharged engine systems. Its proper integration and regular use are key to ensuring the turbocharger and the engine as a whole perform optimally.

-

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.