This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

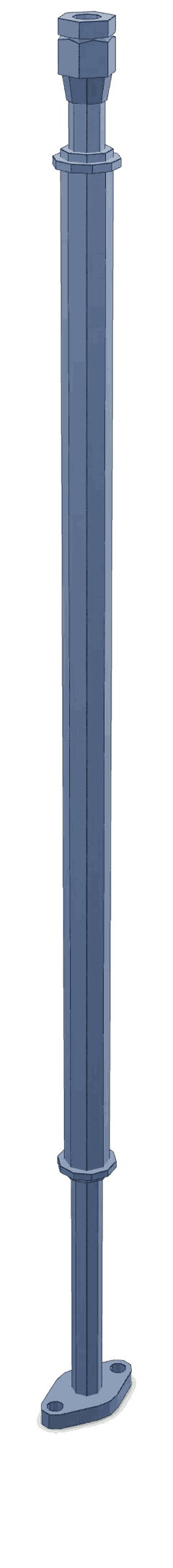

The Turbocharger Oil Drain Connection, identified by Part #4914197, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This part is integral to the turbocharger system in heavy-duty diesel engines, facilitating efficient oil circulation and drainage. Its role ensures the turbocharger operates within optimal parameters, contributing to the overall performance and reliability of the engine 1.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connection, it is important to first grasp the fundamentals of turbochargers. Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. In diesel engines, turbochargers play a pivotal role in enhancing efficiency and power. Oil lubrication is vital for turbocharger operation, as it reduces friction between moving parts, dissipates heat, and removes contaminants, thereby prolonging the turbocharger’s lifespan 2.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It is designed to facilitate the circulation and drainage of oil, ensuring that the turbocharger remains lubricated and cool. This connection allows for the periodic removal of oil, which may contain impurities or have degraded over time, thus maintaining the efficiency and reliability of the turbocharger 3.

Key Features

The Turbocharger Oil Drain Connection is engineered with precision, utilizing high-quality materials to withstand the harsh conditions within a diesel engine. Its design includes specific connection types that ensure a secure fit within the turbocharger system. Unique design elements may include anti-leak features and easy-access points for maintenance, enhancing the part’s functionality and ease of use.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a turbocharger system offers several advantages. It contributes to improved engine performance by ensuring optimal turbocharger lubrication. Additionally, it enhances the reliability of the turbocharger, reducing the likelihood of failures due to inadequate lubrication. From a maintenance perspective, this part simplifies the oil change process, making it more efficient and less time-consuming.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail. The process involves securing the connection to the turbocharger, ensuring a leak-free seal. Specific tools or equipment may be necessary to achieve a proper installation, emphasizing the importance of following manufacturer guidelines to maintain the integrity of the turbocharger system.

Troubleshooting and Maintenance

Common issues with Turbocharger Oil Drain Connections can include leaks or blockages, which may affect turbocharger performance. Diagnostic procedures involve inspecting the connection for signs of wear or damage and ensuring it is securely fitted. Regular maintenance, including checking for leaks and ensuring the connection is free from obstructions, is crucial for optimal performance and longevity of the turbocharger system.

Cummins Overview

Cummins Inc. has a rich history in the automotive industry, known for its commitment to producing high-quality engine components. The company’s reputation is built on a foundation of innovation, reliability, and excellence in manufacturing. Cummins’ dedication to quality is evident in their wide range of engine parts, including the Turbocharger Oil Drain Connection, which is designed to meet the demanding requirements of heavy-duty diesel engines.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection, part number 4914197, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

NH/NT 855 Engines

The NH/NT 855 engines are part of the Cummins engine family that benefit from the Turbocharger Oil Drain Connection. This part is integral to the maintenance and operational integrity of these engines. The NH/NT 855 engines are known for their robust design and are commonly used in heavy-duty applications, including industrial and transportation sectors.

The Turbocharger Oil Drain Connection ensures that any excess oil is effectively removed from the turbocharger, preventing oil build-up that could lead to overheating and potential damage. This part is engineered to withstand the high pressures and temperatures associated with these engines, ensuring longevity and reliability.

Grouping of Engines

The Turbocharger Oil Drain Connection is compatible with a range of Cummins engines beyond the NH/NT 855. This part is designed to fit seamlessly into the lubrication systems of various Cummins engine models, ensuring that the oil drainage process is efficient and effective.

By using the Turbocharger Oil Drain Connection, engine operators can maintain optimal performance and extend the lifespan of their turbochargers. This part is a testament to Cummins’ commitment to providing high-quality components that enhance engine reliability and efficiency.

Role of Part 4914197 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 4914197, is an essential component in the maintenance and operation of turbocharged engine systems. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger is a high-speed component that requires consistent lubrication to reduce friction and wear. The Turbocharger Oil Drain Connection is strategically positioned to allow for the periodic removal of oil that has been circulated through the turbocharger. This process helps in maintaining the cleanliness and viscosity of the oil, which is vital for the turbocharger’s longevity and performance.

Connection to Plumbing Systems

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines and filters. This connection point allows for the safe and controlled release of oil from the turbocharger housing. Proper integration with the plumbing ensures that the oil can be efficiently drained without causing spills or contamination, which could otherwise lead to engine damage or inefficient operation.

Maintenance and Operational Efficiency

Regular drainage of oil from the turbocharger, facilitated by the Turbocharger Oil Drain Connection, is a key maintenance practice. It helps in identifying any contaminants or metal particles that may have entered the oil, indicating potential wear or damage within the turbocharger. This proactive approach to maintenance can prevent more severe issues down the line, ensuring the turbocharger and the entire engine system operate smoothly.

Enhanced Performance and Reliability

By ensuring that the turbocharger is properly lubricated and that old oil is regularly removed, the Turbocharger Oil Drain Connection contributes to the overall performance and reliability of the engine. It allows the turbocharger to spin at high speeds with minimal friction, which is essential for achieving the desired boost levels and engine performance.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 4914197) plays a significant role in the maintenance and operational efficiency of turbocharged engine systems. Its proper integration with the turbocharger and the engine’s plumbing system is essential for ensuring optimal performance, reliability, and longevity of the engine components.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.