This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Oil Drain Connection, identified by part number 3819373, is a component manufactured by Cummins, a leader in diesel engine technology. This part plays a role in the maintenance and operation of heavy-duty truck engines. Its design and function are integral to the efficient operation of turbochargers, which are vital for enhancing engine performance and fuel efficiency in heavy-duty applications.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are designed to facilitate the removal of oil from the turbocharger. This process is fundamental to maintaining the efficiency and longevity of the turbocharger. By ensuring that oil is properly drained, these connections help prevent oil buildup, which can lead to inefficiencies or damage within the turbocharger system. Proper oil management is crucial for the turbocharger’s lubrication system, which reduces friction and wear on moving parts, thereby enhancing overall engine performance 1.

Role and Function in Truck Operation

The Turbocharger Oil Drain Connection serves a specific purpose in the operation of a truck. It allows for the periodic drainage of oil from the turbocharger, which is necessary to maintain optimal performance. By facilitating the removal of oil, this component helps prevent the accumulation of contaminants and ensures that the turbocharger operates within its designed parameters. This, in turn, contributes to the truck’s overall efficiency, reliability, and longevity.

Key Features

The Cummins Turbocharger Oil Drain Connection is characterized by several key features that enhance its functionality and durability. Its design incorporates elements that ensure a secure connection, minimizing the risk of leaks. Additionally, the connection is engineered for ease of maintenance, allowing for straightforward oil drainage procedures. These features contribute to the component’s reliability and efficiency in heavy-duty truck applications.

Benefits

Utilizing the Cummins Turbocharger Oil Drain Connection offers several benefits. It contributes to improved turbocharger performance by ensuring efficient oil management. This, in turn, can extend the lifespan of the turbocharger and other related components. Furthermore, by facilitating easy maintenance, it reduces the overall maintenance requirements for the turbocharger system, leading to cost savings and increased uptime for the vehicle.

Troubleshooting and Maintenance Suggestions

To ensure the reliable operation of the Turbocharger Oil Drain Connection, it is important to be aware of common issues and their signs. Regular inspection for leaks or signs of wear can help identify potential problems early. Maintenance practices should include periodic checks of the connection for tightness and integrity, as well as ensuring that oil drainage procedures are performed according to manufacturer recommendations. These practices help maintain the efficiency and reliability of the turbocharger system.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. It is designed to be compatible with various Cummins turbocharger models, ensuring a seamless integration into the engine system. Specific installation guidelines should be followed to ensure that the connection is secure and functions as intended. These guidelines may include torque specifications and alignment requirements to ensure optimal performance and durability.

Common Myths and Misconceptions

There are several myths and misconceptions surrounding turbocharger oil drain connections. One common misconception is that these connections are not critical to the operation of the turbocharger. In reality, they play a role in maintaining the efficiency and longevity of the turbocharger by ensuring proper oil management. Another myth is that frequent oil drainage can harm the turbocharger. On the contrary, regular maintenance, including oil drainage, is important for the turbocharger’s optimal performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in engine design and manufacturing is reflected in its comprehensive range of components and systems, including the Turbocharger Oil Drain Connection.

Application in L10 MECHANICAL Engines

In the L10 MECHANICAL engine series, the Turbocharger Oil Drain Connection plays a role in maintaining the health of the turbocharger. This part is integral to the oil management system, allowing for the controlled drainage of oil from the turbocharger. Proper oil drainage is crucial to prevent oil accumulation, which can lead to increased wear and potential damage to the turbocharger.

Grouping of Engines

The Turbocharger Oil Drain Connection is compatible with a variety of Cummins engines, ensuring that it can be used across multiple platforms. While the specific engines that utilize this part may vary, it is designed to fit seamlessly into the oil management systems of these engines. The compatibility of this part with different engine models underscores its versatility and importance in maintaining engine performance.

Role of Part 3819373 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 3819373, is integral to the efficient operation of turbochargers in engine systems. This component facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that contaminants are regularly removed.

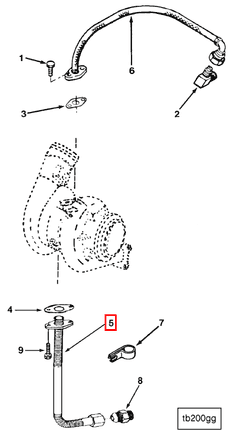

Integration with Turbocharger

In the context of a turbocharger, the oil drain connection is positioned to allow the used oil, which has lubricated the turbocharger’s bearings and other moving parts, to be expelled from the system. This process is essential for maintaining the turbocharger’s performance and longevity. The drained oil is typically returned to the engine’s lubrication system, where it can be filtered and recirculated, promoting a closed-loop lubrication process that conserves oil and reduces waste.

Interaction with Plumbing

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines, filters, and the oil sump. This connection point is designed to ensure a secure and leak-free transfer of oil. The plumbing system must be meticulously designed to handle the pressures and temperatures associated with turbocharger oil, necessitating the use of high-quality materials and precise engineering.

Overall System Functionality

Within the broader engine system, the Turbocharger Oil Drain Connection plays a supportive yet significant role. It ensures that the turbocharger receives consistent lubrication while allowing for the efficient removal of used oil. This balance is vital for the turbocharger’s operation, as it prevents oil buildup that could lead to performance issues or component failure.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3819373) is a key component in the maintenance of turbocharger health and the overall efficiency of the engine system. Its proper function is dependent on its integration with both the turbocharger and the engine’s plumbing system, highlighting the importance of careful design and installation in engine maintenance practices.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.