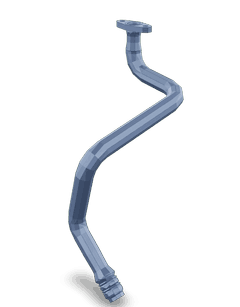

3287818

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #3287818, is a component manufactured by Cummins, a leading provider of diesel engines and powertrain technologies. This part is integral to the maintenance and operation of turbochargers in heavy-duty truck engines. Its design and function are tailored to ensure efficient turbocharger performance and longevity.

Basic Concepts

Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This compression enhances the air density, allowing more fuel to be burned and thus producing more power. Oil lubrication is vital for turbocharger operation, as it reduces friction and wear on moving parts, dissipates heat, and removes contaminants 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It facilitates the draining of oil from the turbocharger, which is necessary to maintain optimal performance. By allowing for periodic oil removal, this connection helps in preventing the buildup of contaminants and ensures that the turbocharger operates within its designed parameters.

Key Features

The Turbocharger Oil Drain Connection is engineered with specific design and construction features to enhance its functionality. It is typically made from durable materials that can withstand the high temperatures and pressures within the turbocharger system. The connection type is designed for secure attachment, ensuring a reliable seal to prevent oil leaks. Unique attributes may include anti-corrosion coatings and precision machining to ensure a perfect fit.

Benefits

Incorporating the Turbocharger Oil Drain Connection into the turbocharger system offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger operates with clean oil. This, in turn, reduces maintenance requirements, as clean oil leads to less wear on turbocharger components. Additionally, the connection enhances turbocharger longevity by facilitating regular oil changes, which is crucial for sustained performance.

Installation Process

Proper installation of the Turbocharger Oil Drain Connection is critical for its effective function. The process involves several steps: first, ensuring the turbocharger is cool and the engine is off to prevent injury. Next, the old connection, if present, is removed using appropriate tools. The new connection is then installed, ensuring a secure fit. Safety precautions include wearing protective gear and following manufacturer guidelines to avoid damage to the turbocharger or injury to the installer.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is necessary to ensure its continued reliable operation. This includes regular inspections for signs of wear or damage, cleaning the connection to remove any debris, and checking for proper sealing. Common issues that may arise include oil leaks or blockages, which can often be addressed by re-tightening the connection or cleaning the area around it. More significant problems may require professional assessment and repair.

Cummins Overview

Cummins Inc. has a long-standing reputation as a leading manufacturer of diesel engines and powertrain technologies for commercial vehicles. Founded in 1919, the company has grown to become a global leader in the industry, known for its innovation, quality, and commitment to customer satisfaction. Cummins’ product lineup includes a wide range of engines, components, and technologies designed to meet the diverse needs of the commercial vehicle market.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection, part number 3287818, is a critical component in the lubrication system of various Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that excess oil is removed and does not accumulate, which could lead to overheating and potential damage.

ISB/ISD4.5 CM2150 B119 and ISD4.5 CM2220 D108

The Turbocharger Oil Drain Connection is compatible with the ISB/ISD4.5 CM2150 B119 and ISD4.5 CM2220 D108 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The part ensures that the turbocharger’s oil is efficiently drained, maintaining optimal operating conditions.

ISBE CM800 and ISB/ISD4.5 CM850

For the ISBE CM800 and ISB/ISD4.5 CM850 engines, the Turbocharger Oil Drain Connection is essential for maintaining the integrity of the turbocharger’s lubrication system. These engines are typically found in medium-duty applications, where reliability and efficiency are paramount. The part’s design ensures that oil is effectively drained, preventing any potential issues related to oil accumulation.

ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, and ISF4.5 CM2220 F123

The Turbocharger Oil Drain Connection is also suitable for the ISF3.8 CM2220 AN, ISF3.8 CM2220 F103, and ISF4.5 CM2220 F123 engines. These engines are part of Cummins’ lineup of high-performance, fuel-efficient engines, often used in both on-highway and off-highway applications. The part’s role in these engines is to ensure that the turbocharger’s oil is drained properly, contributing to the engine’s overall efficiency and longevity.

QSB4.5 CM850 (CM2850)

Lastly, the Turbocharger Oil Drain Connection fits the QSB4.5 CM850 (CM2850) engine. This engine is known for its versatility and is used in a variety of applications, from agricultural to industrial. The part ensures that the turbocharger’s oil is drained effectively, maintaining the engine’s performance and reliability.

Role of Part 3287818 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an integral component within the turbocharger plumbing system of an engine. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

-

Oil Supply Line: The turbocharger oil drain connection interfaces with the oil supply line, which delivers pressurized oil to the turbocharger. This oil is essential for lubricating the turbocharger’s bearings and maintaining its mechanical integrity.

-

Bearing Housing: Within the turbocharger, the oil drain connection is strategically positioned to allow oil that has lubricated the bearing housing to be efficiently drained. This prevents oil accumulation, which could lead to increased temperatures and potential bearing failure.

-

Drainage Path: The connection creates a clear drainage path for used oil to exit the turbocharger. This oil, having served its purpose in lubrication, is routed back to the engine’s oil sump for filtration and recirculation.

-

Sealing Mechanism: To ensure that the turbocharger’s internal components remain sealed from contaminants, the oil drain connection incorporates a sealing mechanism. This prevents any external debris from entering the turbocharger system while allowing smooth oil drainage.

-

Maintenance Access: The design of the oil drain connection also provides easy access for maintenance purposes. Engineers and mechanics can quickly disconnect and reconnect the component for routine checks or replacements, minimizing downtime.

-

Temperature Regulation: By allowing the efficient drainage of oil, the connection helps in regulating the temperature within the turbocharger. Proper oil drainage prevents overheating, which can adversely affect the turbocharger’s performance and longevity.

-

System Pressure Balance: The oil drain connection plays a role in maintaining the pressure balance within the turbocharger system. Efficient oil drainage ensures that the system operates under the correct pressure conditions, enhancing overall performance.

Conclusion

In summary, the Turbocharger Oil Drain Connection is a key element in the turbocharger plumbing, ensuring that the lubrication system functions smoothly, maintaining the turbocharger’s efficiency, and contributing to the engine’s overall performance. Regular maintenance and proper installation of this Cummins part are essential for optimal turbocharger operation and longevity.

References

-

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.