3044929

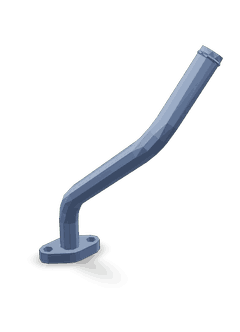

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #3044929, is a component manufactured by Cummins. This part plays a role in the turbocharger system, contributing to efficient operation and reliability. Cummins, a well-established name in the automotive and heavy-duty truck industry, is known for producing high-quality components that enhance engine performance and durability.

Basic Concepts of Turbocharger Oil Drain Connection

To understand the Turbocharger Oil Drain Connection, it is important to first grasp the fundamental principles behind turbochargers. A turbocharger is a device that increases an engine’s efficiency by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power output. The oil drain connection is a component in this system, responsible for facilitating the drainage of oil from the turbocharger. This ensures that the turbocharger remains lubricated and operates within optimal temperature ranges, thereby maintaining system efficiency and reliability 1.

Purpose and Function

The primary purpose of the Turbocharger Oil Drain Connection is to enable the drainage of oil from the turbocharger. During operation, the turbocharger experiences high temperatures and speeds, which necessitate consistent lubrication to prevent wear and damage. The oil drain connection allows used oil to be efficiently removed from the turbocharger, ensuring that fresh, clean oil is always available for lubrication. This process helps in maintaining the turbocharger’s performance and extending its operational lifespan.

Key Features

The Turbocharger Oil Drain Connection is designed with several key features that enhance its performance and durability. Constructed from high-quality materials, this component is built to withstand the high temperatures and pressures associated with turbocharger operation. Its design ensures a secure fit, preventing leaks and ensuring that oil is effectively drained from the system. Additionally, the connection may include features such as seals or gaskets to further enhance its reliability and performance.

Benefits

The Turbocharger Oil Drain Connection offers several advantages that contribute to improved engine performance and system reliability. By ensuring efficient oil drainage, this component helps maintain optimal lubrication within the turbocharger, which is vital for its smooth operation. Additionally, proper lubrication extends the turbocharger’s lifespan by reducing wear and tear. The enhanced reliability of the turbocharger system, in turn, contributes to overall engine performance, making the Turbocharger Oil Drain Connection a valuable component in any turbocharged engine setup.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is vital to ensure its effectiveness and compatibility with various turbocharger models. Installation procedures may vary depending on the specific turbocharger design, but generally involve securing the connection to the turbocharger housing and ensuring a tight seal to prevent leaks. It is important to follow manufacturer guidelines and recommendations to ensure compatibility and optimal performance. Specific requirements or considerations may include torque specifications for tightening bolts and the use of appropriate seals or gaskets.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important to ensure its continued reliability and performance. Regular inspections should be conducted to check for signs of wear, leaks, or blockages. If any issues are detected, such as oil leaks or restricted oil flow, prompt action should be taken to address them. Common troubleshooting steps may include cleaning the connection, replacing seals or gaskets, or, in more severe cases, replacing the connection itself. Adhering to a maintenance schedule and addressing issues promptly can help prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the industry for producing high-quality, reliable components. The company is committed to innovation and excellence, continually striving to enhance the performance and efficiency of its products. Cummins’ dedication to quality and customer satisfaction has made it a trusted name in the automotive and heavy-duty truck sectors.

Turbocharger Oil Drain Connection (Part 3044929) in Cummins Engines

The turbocharger oil drain connection, identified as part 3044929, is a component in the maintenance and operation of several Cummins engine models. This part is integral to the lubrication system, ensuring that the turbocharger operates efficiently and reliably.

N14 CELECT and N14 MECHANICAL Engines

In the N14 CELECT and N14 MECHANICAL engines, the turbocharger oil drain connection plays a role in the oil management system. These engines are known for their robust performance and are widely used in heavy-duty applications. The turbocharger oil drain connection ensures that excess oil is effectively removed from the turbocharger, preventing oil starvation and reducing the risk of bearing failure. This is particularly important in high-stress environments where the turbocharger operates under significant pressure and temperature variations.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the turbocharger oil drain connection is important for maintaining the integrity of the turbocharger’s lubrication system. These engines are designed for durability and efficiency, often used in various industrial and commercial applications. The part ensures that oil is properly drained from the turbocharger, which helps in maintaining optimal performance and longevity of the turbocharger components. This is crucial for engines that operate under heavy loads and varying conditions, where consistent lubrication is key to preventing wear and tear.

Grouping of Engines

The turbocharger oil drain connection (part 3044929) is compatible with the following Cummins engine models:

- N14 CELECT

- N14 MECHANICAL

- NH/NT 855

These engines, while differing in specific applications and configurations, share a common requirement for efficient oil management in their turbocharger systems. The part ensures that the turbocharger operates smoothly by facilitating the proper drainage of oil, which is vital for the overall health and performance of the engine.

Role of Part 3044929 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is a component in the maintenance and operation of turbocharger systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that any contaminants are removed from the oil.

Integration with Turbocharger

In the context of the turbocharger, the oil drain connection is positioned to allow for the periodic removal of oil that has circulated through the turbocharger’s bearings and other moving parts. This helps in maintaining the integrity of the lubrication, preventing the buildup of sludge and other impurities that could impair performance.

Role in Turbocharger Arrangement

Within the turbocharger arrangement, the oil drain connection is typically located at a low point in the system to ensure that it captures the maximum amount of oil. This is particularly important in arrangements where multiple turbochargers are used, as each unit will have its own oil drain connection to maintain individual turbocharger health.

Importance in Turbocharger Mounting

When considering turbocharger mounting, the oil drain connection must be accessible for regular maintenance. Proper mounting ensures that the connection is not obstructed and that oil can be drained efficiently. This is vital for the longevity of the turbocharger and the overall engine system.

Function in Turbocharger Plumbing

In the turbocharger plumbing, the oil drain connection is part of a broader system that includes oil supply lines, return lines, and filtration components. It works in conjunction with these elements to ensure a clean and consistent oil supply to the turbocharger. The efficient drainage of used oil helps in maintaining the pressure and flow characteristics of the lubrication system, which is essential for optimal turbocharger operation.

Conclusion

The Turbocharger Oil Drain Connection (Part 3044929) is a vital component in the maintenance and operation of turbocharger systems, particularly in Cummins engines. Its role in facilitating efficient oil drainage ensures that the turbocharger remains well-lubricated, operates within optimal temperature ranges, and maintains its performance and reliability over time. Proper installation, regular maintenance, and prompt troubleshooting are essential to maximize the benefits of this component and ensure the longevity and efficiency of the turbocharger and engine system.

-

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.