2830895

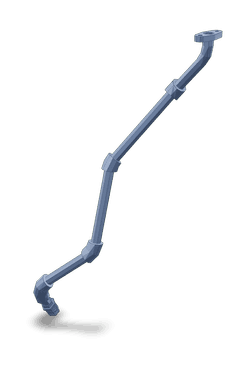

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The 2830895 Turbocharger Oil Drain Connection is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. Its purpose is to ensure that excess oil, which can accumulate during operation, is efficiently removed from the turbocharger system. This process is significant for maintaining the turbocharger’s performance and longevity, as well as ensuring the overall efficiency of the truck’s engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing oil that has lubricated the turbocharger’s moving parts to be drained away. This is important because oil accumulation can lead to increased pressure and temperature within the turbocharger, potentially leading to decreased efficiency and performance. By providing a means for oil to be drained, these connections help maintain optimal operating conditions for the turbocharger 1.

Role and Function in Truck Operation

The 2830895 Turbocharger Oil Drain Connection plays a role in the operation of a truck by contributing to the efficiency of the turbocharger. By ensuring that oil is regularly drained, it helps maintain the turbocharger’s ability to compress air entering the engine, which is vital for achieving higher engine performance. This, in turn, supports the overall efficiency and power output of the truck’s engine 2.

Key Features

The 2830895 Turbocharger Oil Drain Connection is characterized by its design and the materials used in its construction. It is engineered to be compatible with specific turbocharger models, ensuring a secure fit and effective drainage. The connection is made from durable materials that can withstand the high temperatures and pressures associated with turbocharger operation, enhancing its reliability and functionality.

Benefits

The advantages of the 2830895 Turbocharger Oil Drain Connection include improved turbocharger longevity, as regular oil drainage helps prevent the buildup of contaminants that can lead to wear and tear. Additionally, it contributes to enhanced engine performance by ensuring the turbocharger operates under optimal conditions. Furthermore, by reducing the need for frequent maintenance, it can lead to potential cost savings for truck operators 3.

Installation Process

Installing the 2830895 Turbocharger Oil Drain Connection requires following a step-by-step process to ensure a secure and effective fit. This involves using the necessary tools to connect the drain line to the turbocharger, ensuring all connections are tight and secure. Precautions should be taken to avoid damaging the turbocharger or the drain connection during installation. Best practices include verifying the compatibility of the connection with the turbocharger model and following the manufacturer’s guidelines for installation.

Maintenance Tips

To ensure the longevity and efficiency of the 2830895 Turbocharger Oil Drain Connection, regular maintenance practices are recommended. This includes inspecting the connection for signs of wear or damage at specified intervals and cleaning the drain line to prevent blockages. Adhering to these maintenance tips can help maintain the performance of the turbocharger and the overall efficiency of the truck’s engine.

Troubleshooting Common Issues

Common problems associated with turbocharger oil drain connections can include leaks or blockages in the drain line. Troubleshooting these issues involves identifying the source of the problem, whether it be a loose connection or a clogged drain line, and taking the appropriate steps to address it. Solutions may include tightening connections or cleaning the drain line to ensure proper functionality.

Compatibility and Applications

The 2830895 Turbocharger Oil Drain Connection is designed to be compatible with specific Cummins engines, ensuring it meets the requirements for efficient turbocharger operation. Its applications span across various heavy-duty truck models, providing a reliable solution for turbocharger oil drainage in these vehicles.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its diesel engines and components. With a rich history and a diverse product range, Cummins has established a reputation for quality and reliability in the production of engine parts and systems, including turbochargers and their associated components like the 2830895 Turbocharger Oil Drain Connection.

Understanding the Role of Part 2830895 Turbocharger Oil Drain Connection in Engine Systems

The 2830895 turbocharger oil drain connection is a vital component in the efficient operation of turbocharger plumbing within engine systems. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the oil drain connection plays a significant role by providing a dedicated pathway for oil to be returned from the turbocharger to the engine’s lubrication system. This is particularly important in high-performance and high-stress environments where the turbocharger is subjected to extreme temperatures and pressures.

Function within the Lubrication System

The oil drain connection ensures that the oil used to lubricate the turbocharger’s moving parts is efficiently circulated back into the engine’s oil sump. This continuous circulation helps maintain the viscosity and temperature of the oil, which is vital for the longevity and performance of the turbocharger.

Interaction with Other Components

-

Turbocharger Bearings: The drained oil often passes through or around the turbocharger bearings, which are critical for the smooth rotation of the turbine and compressor wheels. Efficient oil drainage helps prevent oil buildup, which could lead to increased friction and wear.

-

Oil Return Lines: The oil drain connection is typically linked to the oil return lines that guide the used oil back to the engine sump. This ensures that the oil can be re-filtered and re-lubricated before being recirculated.

-

Turbocharger Housing: The connection is usually mounted on the turbocharger housing, allowing for a secure and leak-free passage of oil. This mounting ensures that the oil drain process does not interfere with the turbocharger’s primary function of compressing intake air.

Maintenance and Efficiency

Regular maintenance of the oil drain connection is necessary to ensure that it remains free from blockages and leaks. A well-maintained connection contributes to the overall efficiency of the turbocharger system, reducing the risk of oil contamination and ensuring that the turbocharger operates within its designed parameters.

Conclusion

In summary, the 2830895 turbocharger oil drain connection is a vital component in the turbocharger plumbing system, facilitating the efficient return of oil to the engine’s lubrication system and contributing to the sustained performance and reliability of the turbocharger. Regular maintenance and proper installation are key to ensuring its effectiveness and the overall efficiency of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.