This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

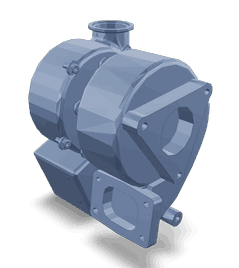

The Cummins 5370734 turbocharger is designed to enhance the performance of commercial truck engines by increasing efficiency and power output through the compression of intake air, allowing more air to enter the combustion chamber. This results in more efficient fuel combustion and improved overall engine performance. The significance of this Cummins part in the operation of commercial trucks lies in its ability to optimize engine performance, making it a valuable component for fleet operators looking to maximize efficiency and power 1.

Basic Concepts of Turbocharging

Turbocharging is a technology that increases an engine’s power output by forcing extra air into the combustion chamber. This is achieved through a turbocharger, which consists of a turbine and a compressor connected by a shaft. As exhaust gases exit the engine, they spin the turbine, which in turn spins the compressor. The compressor draws in and compresses ambient air, which is then fed into the engine’s intake system. The benefits of using a turbocharger include increased power output, improved fuel efficiency, and enhanced engine responsiveness 2.

Role of the 5370734 Turbocharger in Truck Operation

The 5370734 turbocharger enhances engine performance and efficiency by compressing the intake air, allowing for more efficient fuel combustion, resulting in increased power output and improved fuel economy. This turbocharger is designed to work seamlessly with Cummins engines, ensuring optimal performance and reliability in demanding commercial truck applications 3.

Key Features of the 5370734 Turbocharger

The 5370734 turbocharger incorporates advanced materials and engineering techniques to ensure durability and performance. Its design features a robust housing, precision-machined compressor and turbine wheels, and a high-efficiency bearing system. These features contribute to its reliability and efficiency, making it a preferred choice for commercial truck applications 4.

Benefits of Using the 5370734 Turbocharger

The use of the 5370734 turbocharger offers several benefits for commercial truck operators, including improved engine performance, increased fuel efficiency, and enhanced durability. The turbocharger’s ability to compress intake air results in more efficient fuel combustion, leading to increased power output and better fuel economy. Additionally, its robust design and high-quality materials ensure long-term reliability and performance, reducing the need for frequent maintenance and repairs 1.

Installation and Integration

When installing the 5370734 turbocharger into a commercial truck engine, it is important to consider compatibility with various engine models and configurations. Proper installation ensures optimal performance and longevity of the turbocharger. Guidelines for installation include ensuring a proper seal between the turbocharger and the engine, verifying the correct orientation of the turbocharger, and checking for any obstructions or interferences that may affect its operation 2.

Performance Enhancements

The 5370734 turbocharger contributes to performance enhancements in commercial trucks by increasing horsepower, torque, and overall engine responsiveness. Its efficient compression of intake air allows for more complete fuel combustion, resulting in increased power output. Additionally, the turbocharger’s design ensures smooth and responsive engine operation, enhancing the driving experience for commercial truck operators 3.

Maintenance and Troubleshooting

Maintaining and troubleshooting the 5370734 turbocharger is essential for ensuring optimal performance and longevity. Common issues may include oil leaks, compressor wheel damage, or turbine wheel imbalance. Diagnostic procedures involve inspecting the turbocharger for signs of wear or damage, checking oil levels and quality, and performing a visual inspection of the compressor and turbine wheels. Recommended maintenance practices include regular oil changes, inspecting and replacing worn or damaged components, and following the manufacturer’s guidelines for maintenance intervals 4.

Cummins Corporation

Cummins Corporation is a renowned manufacturer of diesel engines, with a strong reputation in the industry for innovation and quality. Founded in 1919, Cummins has a long history of producing reliable and efficient engines for a variety of applications, including commercial trucks, construction equipment, and power generation. The company is committed to advancing technology and improving the performance and efficiency of its products, making it a trusted choice for fleet operators and engine manufacturers alike 1.

Turbocharger Part 5370734 by Cummins

The turbocharger part 5370734, manufactured by Cummins, is engineered to fit seamlessly with the F2.8 CM2620 F135B and ISF2.8 CM2220 F117 engines, ensuring optimal efficiency and power output. For the F2.8 CM2620 F135B engine, the turbocharger is specifically tailored to meet the engine’s unique requirements, providing the necessary boost to enhance fuel efficiency and power. Similarly, the ISF2.8 CM2220 F117 engine benefits from the turbocharger, which is engineered to fit perfectly within the engine’s system, ensuring efficient and reliable operation. The turbocharger’s design allows it to work in harmony with the engine, providing the necessary boost to improve performance and reduce emissions 2.

Role of Part 5370734 Turbocharger in Engine Systems

Part 5370734, a turbocharger, significantly enhances the performance of engine systems by increasing efficiency and power output. When integrated into an engine, this component works in conjunction with several other parts to optimize overall functionality.

Integration with the Intake System

The turbocharger is positioned between the engine’s intake manifold and the air filter. Its primary function is to compress the incoming air before it enters the combustion chamber. This compressed air allows for more fuel to be burned, resulting in increased power output. The turbocharger is connected to the intake system via a series of hoses and pipes, ensuring a smooth flow of air 3.

Connection to the Exhaust System

On the exhaust side, the turbocharger is linked to the exhaust manifold. The turbine within the turbocharger is driven by the exhaust gases, which spin the compressor turbine on the intake side. This setup creates a symbiotic relationship where the exhaust gases provide the necessary energy to compress the intake air 4.

Interaction with the Intercooler

In many engine systems, an intercooler is used in conjunction with the turbocharger. The intercooler cools the compressed air from the turbocharger before it enters the engine. This cooling process increases the air density, allowing even more air (and thus more fuel) to be combusted, further enhancing engine performance 1.

Role in the Fuel Injection System

The turbocharger’s ability to increase air intake directly influences the fuel injection system. With more air available, the fuel injectors can deliver a greater amount of fuel, optimizing the air-fuel ratio for combustion. This results in more efficient burning and increased power 2.

Impact on the Engine Control Unit (ECU)

The turbocharger also interacts with the Engine Control Unit (ECU). Sensors monitor the turbocharger’s performance, providing data to the ECU. The ECU then adjusts various parameters such as fuel delivery, ignition timing, and boost pressure to ensure optimal engine performance and protection 3.

Contribution to the Overall Engine Efficiency

By increasing the amount of air and fuel that can be combusted, the turbocharger plays a key role in improving the engine’s overall efficiency. This not only results in higher power output but also enhances the engine’s responsiveness and torque, making it more suitable for a variety of driving conditions 4.

Conclusion

The Cummins 5370734 turbocharger is a critical component for enhancing the performance and efficiency of commercial truck engines. Its advanced design and features ensure reliable and efficient operation, contributing to increased power output, improved fuel economy, and enhanced engine responsiveness. Proper installation, maintenance, and troubleshooting are essential for ensuring the longevity and optimal performance of this turbocharger in demanding commercial truck applications.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ ↩ ↩ ↩ -

Automotive Systems Principles and Practice, G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, CRC Press, 2011

↩ ↩ ↩ ↩ -

The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Giancarlo Genta and Lorenzo Morello, Springer, 2019

↩ ↩ ↩ ↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.